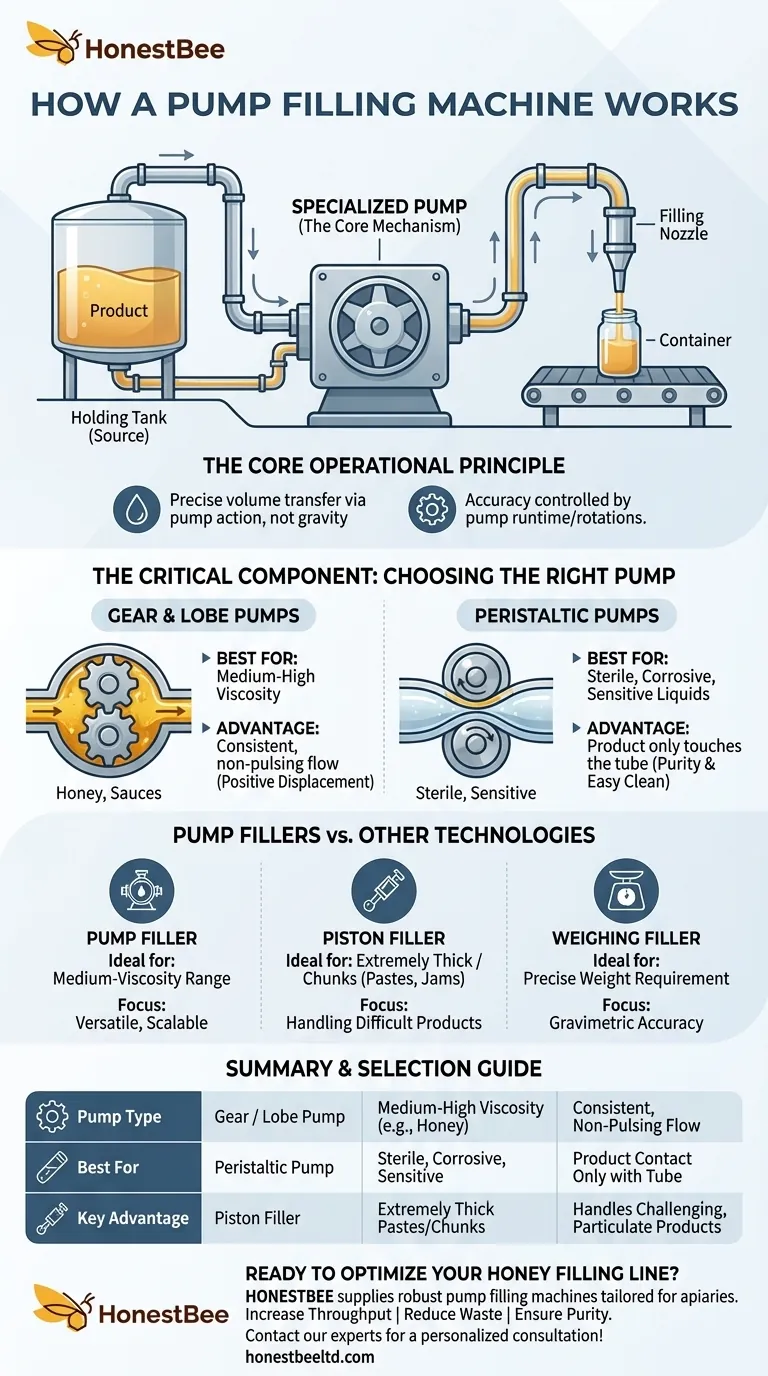

At its core, a pump filling machine works by using a specialized pump to transfer a precise volume of liquid from a holding tank directly into a container. Unlike other methods that rely on pistons or gravity, the pump itself is the primary mechanism for moving and measuring the product, making the choice of pump technology the most critical factor in the machine's operation.

The key takeaway is that pump filling isn't a single technology, but a category of machines. The effectiveness of a pump filler depends entirely on matching the right type of pump—such as a gear, lobe, or peristaltic pump—to the specific characteristics of your liquid.

The Core Operational Principle

The process is straightforward but highly controllable. It involves a simple, continuous path from product source to final container, managed entirely by the pump's action.

The Flow of Liquid

A pump draws the product from a bulk source, like a hopper or tank. It then forces that liquid through tubing or pipes to one or more filling nozzles positioned over the containers.

Achieving Fill Accuracy

Accuracy is controlled by the pump's operation. The machine can be programmed to run the pump for a specific amount of time or for a set number of rotations, which corresponds to a precise and repeatable volume of liquid being dispensed.

The Critical Component: Choosing the Right Pump

The "pump" in a pump filler is not one-size-fits-all. The type of pump used defines the machine's capabilities and its ideal applications.

Gear and Lobe Pumps: The Workhorses for Viscosity

These pumps operate on a positive displacement principle. Interlocking gears or lobes rotate to create a consistent, non-pulsing flow, which is highly effective for moving medium- to high-viscosity liquids like sauces, creams, and honey.

Peristaltic Pumps: The Choice for Purity and Precision

Peristaltic pumps use rollers to squeeze a flexible tube, pushing the liquid through it. The major advantage is that the product only ever touches the inside of the tube.

This makes them perfect for sterile, corrosive, or sensitive liquids. It also allows for incredibly fast and easy clean-up and product changeover, as you can simply replace the tube for the next production run.

Pump Fillers vs. Other Technologies

Understanding when to choose a pump filler requires comparing it to other common filling methods.

When to Choose a Pump Filler

Pump fillers excel with a wide range of medium-viscosity liquids. They are a popular and scalable choice for operations where the product's characteristics are well-matched to a specific pump technology (e.g., honey with a gear pump, or pharmaceutical liquids with a peristaltic pump).

When to Consider a Piston Filler

A piston filler uses a cylinder and piston to draw in and dispense a product. This mechanism is exceptionally versatile and is often superior for handling extremely thick products like pastes or liquids containing large particles (e.g., salsa or jams).

When to Use a Weighing Filler

Both pump and piston fillers are volumetric, meaning they dispense a set volume. A weighing filler is gravimetric—it dispenses product until a target weight is reached. This method is essential when product density varies or when precise weight is a legal or quality requirement.

Understanding the Trade-offs

While versatile, pump fillers are not without their specific limitations and considerations.

Flexibility vs. Specificity

The machine's flexibility is dictated by its pump. A machine configured with a gear pump for thick sauces will not be suitable for filling a thin, sterile liquid, which would require a peristaltic setup.

Maintenance and Cleaning

Peristaltic pumps are the easiest to clean, often requiring only a tube change. Gear and lobe pumps, however, must be fully disassembled and sanitized between product runs, which requires more downtime.

Making the Right Choice for Your Product

Selecting the correct filling technology is about aligning the machine's capabilities with the unique properties of your product.

- If your primary focus is medium- to high-viscosity liquids like honey or gels: A gear or lobe pump filler is your most direct and efficient solution.

- If your primary focus is sterile, corrosive, or sensitive products: A peristaltic pump filler offers unmatched product isolation and rapid, sanitary changeovers.

- If your primary focus is extremely thick pastes or products with chunks: You should evaluate a piston filler, as it is often better suited for these challenging applications.

- If your primary focus is achieving precise package weight regardless of volume: A weighing filler is the correct technology for your goal.

Ultimately, understanding how the pump dictates the machine's function is the key to mastering your filling process.

Summary Table:

| Pump Type | Best For | Key Advantage |

|---|---|---|

| Gear / Lobe Pump | Medium- to high-viscosity liquids (e.g., honey, sauces) | Positive displacement for consistent, non-pulsing flow |

| Peristaltic Pump | Sterile, corrosive, or sensitive liquids | Product only touches the tube; easy clean-up and changeover |

| Piston Filler | Extremely thick pastes or products with chunks | Superior for handling challenging, particulate-laden products |

Ready to Optimize Your Honey Filling Line?

As a commercial beekeeper or beekeeping equipment distributor, precise and efficient filling is critical for your honey and hive product operations. HONESTBEE supplies robust, high-performance pump filling machines and equipment tailored for the unique demands of apiaries.

We can help you:

- Increase throughput with accurate, high-speed filling systems.

- Reduce product waste with precise volume control for honey and other viscous liquids.

- Ensure product purity with equipment designed for easy sanitation.

Let's discuss the best filling solution for your specific products. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- What are the capacity options for stainless steel screw honey pumps? Choose the Right Flow for Your Apiary

- What are the advantages of using an electric vacuum pump for Melipona subnitida honey? Precision Harvesting Solutions

- What role do honey pumps play in the honey processing workflow? Optimize Efficiency and Preserve Quality

- What are the advantages of using a honey suction pump vs squeezing? Boost Stingless Bee Honey Purity & Hive Health

- What is the primary role of the Honey Suction Pump? Boost Efficiency in Stingless Bee Honey Harvesting

- Who are the typical users of stainless steel screw honey pumps? From Commercial Beekeepers to Hobbyists

- What role do industrial-scale mixing and pumping machines play in honey bee feeding management? Enhance Apiary Efficiency

- Why is the use of professional extraction tools like low-pressure suction pumps necessary for harvesting honey? Learn More