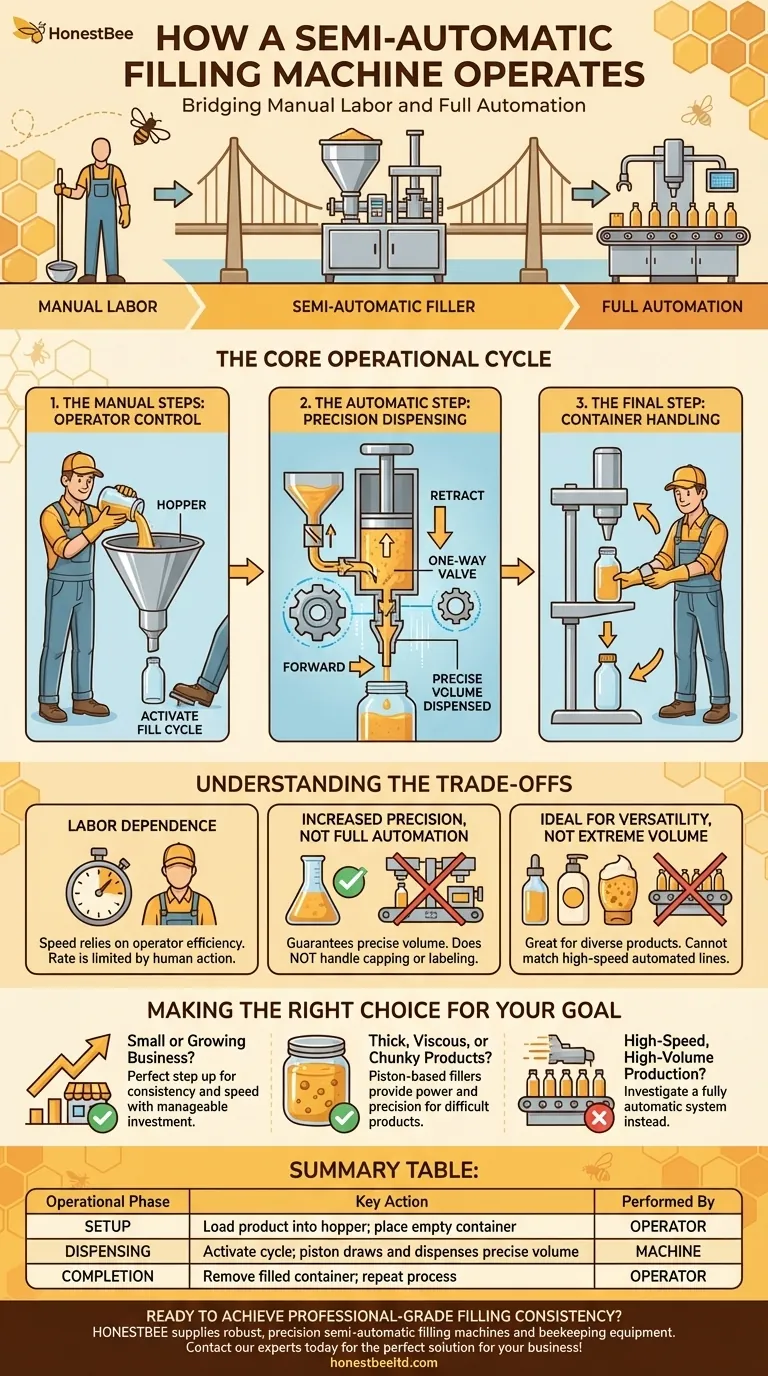

In essence, a semi-automatic filling machine bridges the gap between manual labor and full automation. An operator manually loads the bulk product into a hopper and places containers for filling, while the machine uses a precise, automated mechanism to dispense a consistent amount of product every time.

The core principle is a division of labor: a human performs the preparatory steps, and the machine executes the repetitive, precision-critical task of filling. This offers a significant upgrade in consistency and speed over manual methods without the complexity of a fully automated system.

The Core Operational Cycle

A semi-automatic filler operates on a simple, repeatable cycle that combines human action with machine precision. Understanding this workflow is key to seeing its value.

The Manual Steps: Operator Control

The "semi" in semi-automatic refers to the essential role of the human operator.

The operator is responsible for loading the bulk product, whether it's a liquid, cream, or powder, into the machine's main hopper. They also place each empty container under the filling nozzle and activate the fill cycle, often with a foot pedal or button.

The Automatic Step: Precision Dispensing

Once activated, the machine takes over the most critical task: dispensing the exact amount of product.

A common and highly versatile mechanism for this is the piston filler. A piston inside a cylinder retracts, drawing a precise volume of product from the hopper through a valve.

When the piston moves forward, the valve switches, and the product is pushed out through a nozzle and into the waiting container. This mechanical action ensures each fill is virtually identical.

The Final Step: Container Handling

After the machine completes its fill cycle, the operator removes the filled container and replaces it with an empty one to begin the process again. This is the final manual component of the cycle.

Understanding the Trade-offs

While powerful, this technology is designed for a specific scale of operation. It’s crucial to understand its limitations to determine if it’s the right fit.

Labor Dependence

The machine's output speed is entirely dependent on the operator's efficiency. The rate at which an operator can place and remove containers directly dictates the production throughput.

Increased Precision, Not Full Automation

The machine guarantees a precise fill volume, but it does not handle tasks like container feeding, capping, or labeling. These remain separate, often manual, processes.

Ideal for Versatility, Not Extreme Volume

These fillers excel at handling a wide range of product types, from thin liquids to thick pastes with particulates. However, they cannot match the sheer speed of a fully integrated, automated production line designed for a single product at massive scale.

Making the Right Choice for Your Goal

Selecting the right equipment depends entirely on your production needs, product type, and business scale.

- If your primary focus is moving beyond manual filling for a small or growing business: A semi-automatic filler is the perfect next step, offering consistency and speed at a manageable investment.

- If your primary focus is handling thick, viscous, or chunky products: Piston-based semi-automatic fillers provide the power and precision needed for products that are difficult to fill by hand.

- If your primary focus is high-speed, high-volume production with minimal labor: You should bypass this category and investigate a fully automatic filling system.

By combining human oversight with mechanical precision, a semi-automatic filler empowers growing businesses to achieve professional-grade consistency.

Summary Table:

| Operational Phase | Key Action | Performed By |

|---|---|---|

| Setup | Load product into hopper; place empty container | Operator |

| Dispensing | Activate cycle; piston draws and dispenses precise volume | Machine |

| Completion | Remove filled container; repeat process | Operator |

Ready to achieve professional-grade filling consistency? HONESTBEE supplies robust, precision semi-automatic filling machines and beekeeping equipment to commercial apiaries and distributors. Our wholesale-focused operations ensure you get the reliable equipment you need to scale your production efficiently. Contact our experts today to find the perfect solution for your business!

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Manual Honey Filling Machine Bottling Machine for Honey

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

People Also Ask

- In what way do automated honey filling and processing machines increase beekeeping value? Boost Plantation ROI

- How do automatic quantitative filling systems ensure consistency in honey? Achieve Perfect Flavored Honey Precision

- How do specialized honey-filling machines contribute to the processing stage? Elevate Your Branding and Hygiene

- How does automated honey filling and sealing equipment contribute to product quality control? Ensure Stability & Purity

- What is the working principle of a honey stick packing machine? Automate Your Honey Production Line

- What are the advantages of integrating professional-grade honey-filling machines? Scaling Your Production for Growth

- What are the best practices for achieving professional-looking honey bottling results? Master the Art of Honey Packaging

- Why is honey filling and processing machinery essential for cooperatives? Scaling Success with HONESTBEE Technology