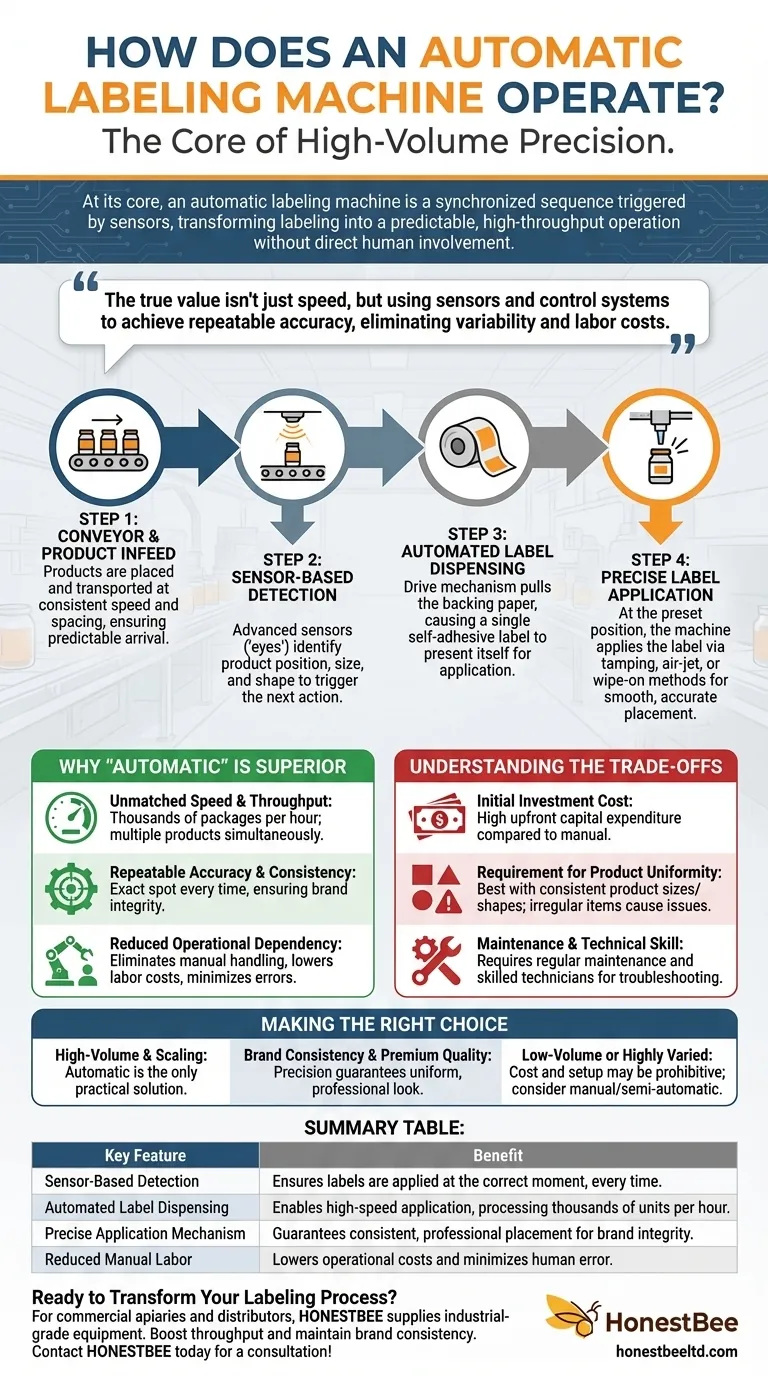

At its core, an automatic labeling machine operates through a synchronized sequence of events triggered by sensors. As a product moves along a conveyor belt, a sensor detects its presence, signaling the machine to dispense a single label from a roll and apply it with high precision to a predetermined spot on the product, all without any direct human involvement.

The true value of an automatic labeling machine isn't just its speed, but its ability to use sensors and control systems to achieve repeatable accuracy. This eliminates the variability and labor costs associated with manual processes, transforming labeling into a predictable, high-throughput operation.

The Core Mechanism: From Detection to Application

To understand how these machines achieve such efficiency, it's best to break down the process into four distinct, automated steps. Each stage is perfectly timed and controlled by the machine's central system.

Step 1: The Conveyor and Product Infeed

Products are placed onto a conveyor belt, which transports them at a consistent speed and spacing. This controlled movement is the foundation for the entire process, ensuring each item arrives at the labeling station in a predictable manner.

Step 2: Sensor-Based Detection

As the product enters the labeling zone, one or more sensors detect its arrival. These advanced sensors can identify the product's position, and sometimes even its size and shape, serving as the trigger for the next action. This is the "eyes" of the operation.

Step 3: Automated Label Dispensing

Once the sensor is triggered, the machine's drive mechanism instantly pulls on the label roll backing paper. This action causes a single self-adhesive label to peel away and present itself, ready for application.

Step 4: Precise Label Application

The moment the product is in the correct preset position, the machine applies the dispensed label. This can be done using a variety of methods, such as a tamping arm, an air-jet system, or by wiping the label onto the product as it passes by, ensuring it is affixed smoothly and accurately.

What Makes "Automatic" Labeling Superior?

The switch from manual or semi-automatic methods to a fully automatic system is driven by clear operational advantages that impact efficiency, quality, and cost.

Unmatched Speed and Throughput

An automatic labeler can process thousands of packages per hour, a rate impossible to sustain manually. Some systems can even label multiple products simultaneously, dramatically increasing overall production capacity.

Repeatable Accuracy and Consistency

The combination of sensors and control systems ensures that every label is placed in the exact same spot on every product. This level of consistency is critical for brand integrity and professional appearance, eliminating the human error common in manual application.

Reduced Operational Dependency

By automating the entire process, you remove the need for an operator to handle each individual item. This reduces direct labor costs, minimizes the risk of repetitive strain injuries, and frees up personnel for more complex tasks.

Understanding the Trade-offs

While powerful, automatic labeling systems are not a universal solution. An objective assessment requires understanding their limitations.

Initial Investment Cost

A significant drawback is the high upfront capital expenditure. Fully automatic systems are a major investment compared to far less expensive manual or semi-automatic alternatives.

Requirement for Product Uniformity

These machines perform best with consistent product sizes, shapes, and spacing on the conveyor. Highly irregular products or inconsistent feeding can lead to application errors and require more complex, and thus more expensive, handling systems.

Maintenance and Technical Skill

Automatic labelers are sophisticated machines with mechanical and electronic components that require regular maintenance. Troubleshooting and changeovers for different products often demand a higher level of technical skill than simpler equipment.

Making the Right Choice for Your Operation

Choosing the correct labeling method depends entirely on your production goals, product characteristics, and budget.

- If your primary focus is high-volume production and scaling: An automatic labeling machine is the only practical solution to meet demand efficiently.

- If your primary focus is brand consistency and premium quality: The machine's precision guarantees a uniform, professional look across your entire product line.

- If your primary focus is low-volume runs or highly varied products: The cost and setup time of an automatic system may be prohibitive, making a semi-automatic or manual approach more sensible.

Ultimately, selecting the right technology is about aligning the tool's capabilities with the scale and quality demands of your business.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Sensor-Based Detection | Ensures labels are applied at the correct moment, every time. |

| Automated Label Dispensing | Enables high-speed application, processing thousands of units per hour. |

| Precise Application Mechanism | Guarantees consistent, professional placement for brand integrity. |

| Reduced Manual Labor | Lowers operational costs and minimizes human error. |

Ready to Transform Your Labeling Process?

For commercial apiaries and distributors, accurate and efficient product labeling is non-negotiable. HONESTBEE supplies industrial-grade beekeeping equipment and supplies through wholesale-focused operations. An automatic labeling machine from our product line can ensure your honey jars, propolis containers, and other goods are labeled with the speed and precision your business demands.

Let us help you boost your production throughput and maintain impeccable brand consistency. Contact HONESTBEE today for a consultation on the right labeling solution for your operation!

Visual Guide

Related Products

- Automatic In-Line Flat Surface Labeling Machine

- Semi Automatic Round Bottle Labeling Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

- HONESTBEE Professional Bee Frame Machine for Side Bar Shaping

- Queen Bee Catcher Plastic Bee Marker Bottle with Piston Marking Tube

People Also Ask

- Why are professional product labeling and packaging design tools indispensable? Elevate Your Beekeeping Brand Identity

- How does an automatic labeling machine reduce labor costs? Slash Overhead & Boost Productivity

- What is the significance of automated filling and labeling systems in honey quality? Build Consumer Trust with Precision

- How do professional packaging designs and labeling materials affect the marketing of honey products? Boost brand value!

- How do quality labels function as critical consumables for premium honey? Elevate Brand Trust and Market Position

- What is the function of a labeling machine? Automate Your Product Identification and Branding

- How do automated labeling systems contribute to building consumer trust for honey producers? Gain Brand Credibility

- What factors influence the choice of material for honey labels? Optimize Your Packaging for Maximum Shelf Impact