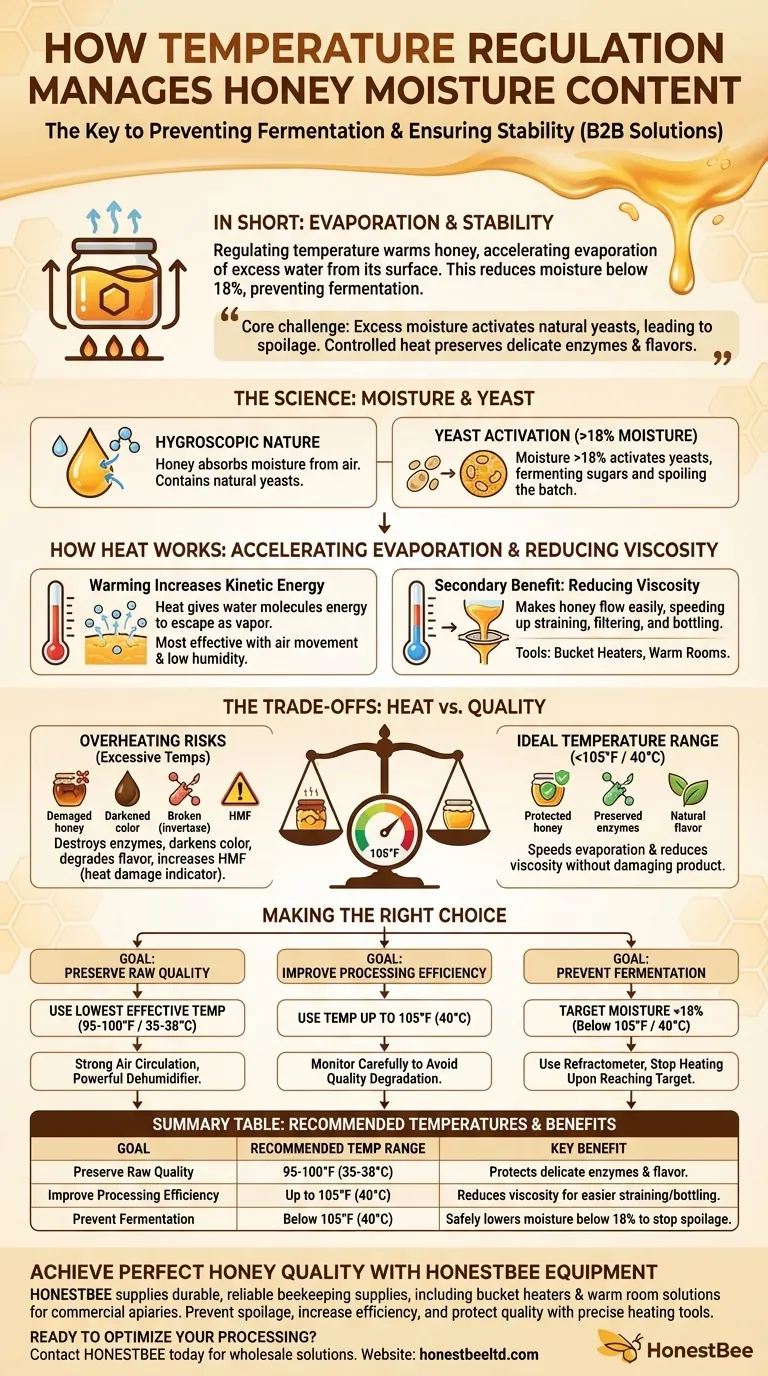

In short, regulating temperature allows you to carefully warm honey, which accelerates the evaporation of excess water from its surface. This process is the primary method for reducing honey's moisture content to a safe level, preventing fermentation and ensuring its long-term stability.

The core challenge with honey is that excess moisture activates natural yeasts, leading to spoilage. Applying controlled, gentle heat is the most effective tool for driving off this moisture while preserving the delicate enzymes and flavors that define high-quality honey.

The Science of Honey and Water Content

Why Moisture Content is Critical

Honey is hygroscopic, meaning it can absorb moisture from the surrounding air. It also naturally contains osmophilic yeasts.

When the water content in honey rises above approximately 18%, these dormant yeasts can become active and begin to ferment the sugars, spoiling the batch.

How Temperature Accelerates Evaporation

Warming honey increases the kinetic energy of its water molecules. This gives them enough energy to escape the honey's surface as water vapor.

This process is most effective when combined with air movement and low ambient humidity, which helps carry the evaporated moisture away from the honey.

Practical Impacts of Temperature Control

Reducing Viscosity for Processing

A significant secondary benefit of warming honey is the dramatic reduction in its viscosity. Cold honey is thick and difficult to work with.

By raising the temperature, honey flows much more easily. This makes essential processing steps like straining, filtering, and bottling significantly faster and more efficient.

The Role of Heaters and Warm Rooms

Beekeepers and processors commonly use tools like bucket heaters or dedicated "warm rooms."

These methods apply gentle, consistent heat to the honey containers. When used with a dehumidifier and fans for air circulation, they create an ideal environment to safely and efficiently lower the moisture content.

Understanding the Trade-offs: Heat vs. Quality

The Risk of Overheating

Applying too much heat is highly detrimental to honey quality. Excessive temperatures can destroy beneficial enzymes, such as diastase and invertase.

Overheating also darkens the honey, degrades its delicate flavor profile, and increases the levels of Hydroxymethylfurfural (HMF), an indicator of heat damage.

The Ideal Temperature Range

To reduce moisture without damaging the product, most professionals keep temperatures below 105°F (40°C).

This range is warm enough to significantly speed up evaporation and reduce viscosity but low enough to protect the honey's natural enzymes and flavor compounds.

Making the Right Choice for Your Goal

By understanding the principles, you can apply heat strategically to achieve your specific objective.

- If your primary focus is preserving raw honey quality: Use the lowest effective temperature (around 95-100°F or 35-38°C) combined with strong air circulation and a powerful dehumidifier to do the heavy lifting.

- If your primary focus is processing efficiency: A temperature closer to 105°F (40°C) will make honey flow much faster for bottling, but requires careful monitoring to avoid degrading its quality.

- If your primary focus is preventing fermentation: Your non-negotiable goal is to get moisture below 18%; use a refractometer to measure your progress and stop the heating process as soon as you reach your target.

By carefully managing temperature, you take direct control over your honey's stability, quality, and longevity.

Summary Table:

| Goal | Recommended Temperature Range | Key Benefit |

|---|---|---|

| Preserve Raw Quality | 95-100°F (35-38°C) | Protects delicate enzymes and flavor. |

| Improve Processing Efficiency | Up to 105°F (40°C) | Reduces viscosity for easier straining/bottling. |

| Prevent Fermentation | Below 105°F (40°C) | Safely lowers moisture below 18% to stop spoilage. |

Achieve Perfect Honey Quality and Stability with the Right Equipment

Mastering temperature control is essential for commercial-scale honey production. HONESTBEE supplies durable, reliable beekeeping supplies and equipment—including bucket heaters and warm room solutions—designed specifically for the needs of commercial apiaries and beekeeping equipment distributors.

We help you:

- Prevent spoilage with equipment that enables precise, gentle heating.

- Increase processing efficiency with tools that reduce honey viscosity.

- Protect your product's quality by avoiding the risks of overheating.

Ready to optimize your honey processing? Contact HONESTBEE today to discuss wholesale solutions for your operation.

Visual Guide

Related Products

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

People Also Ask

- What are the technical requirements for honey liquefaction? Ensure Quality with Precise Temperature Control

- What are the key characteristics to look for in a honey warming source? Preserve Quality with Gentle Heat Control

- What core values does a precision constant temperature water bath system provide in low-heat honey processing? Guide

- How hot can you heat honey without damaging it? Preserve Flavor & Enzymes

- What is the function of thermostatic heating equipment in honey analysis? Optimize Sample Accuracy and Consistency

- How to use honey that has hardened? Safely Restore Its Liquid Form with Gentle Heat

- How do you make Crystallised honey runny again? The Safe & Simple Guide to Restoring Liquid Honey

- What are the benefits of precise temperature control in honey heating tanks? Preserve Quality and Efficiency