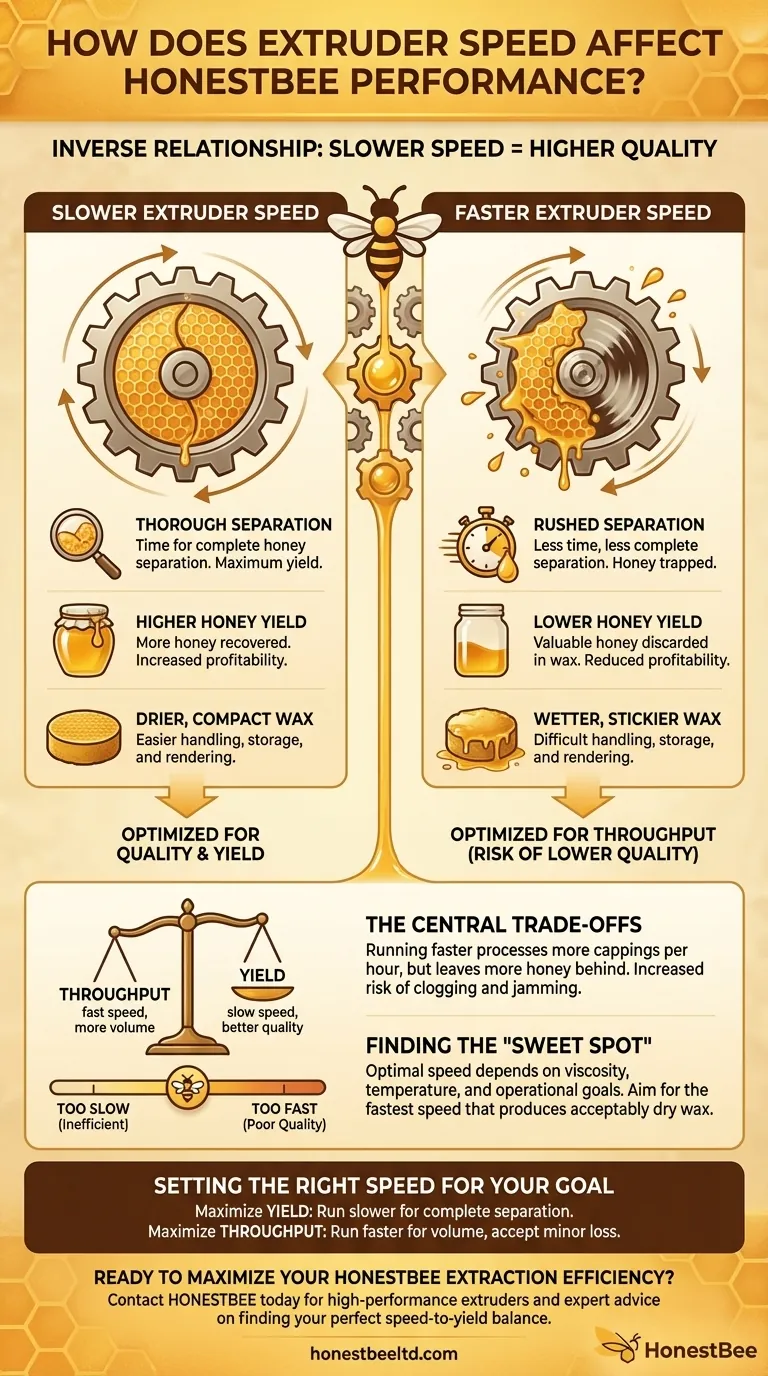

In short, the speed of a honey extruder has an inverse relationship with its performance quality. A slower operational speed allows the machine to more precisely and completely separate the honey from the wax cappings.

The central trade-off in honey extrusion is between speed and quality. While faster speeds increase throughput, they reduce the efficiency of separation, leaving more valuable honey trapped in the discarded wax.

The Core Principle: Time and Pressure

Why Slower is More Precise

A honey extruder works by applying mechanical pressure to a mixture of honey and wax cappings. This forces the liquid honey out through filters or screens while compacting the solid wax.

The process is fundamentally dependent on time. Honey, being a viscous fluid, requires a certain amount of time to flow away from the compressed wax and navigate the exit channels.

The Sponge Analogy

Think of squeezing a water-logged sponge. A quick, forceful squeeze will get a lot of water out, but the sponge remains quite damp. A slow, steady squeeze gives the water time to travel from the center to the outside, resulting in a much drier sponge.

An extruder operates on the same principle. Slower speeds provide the necessary time for a more complete extraction.

How Speed Directly Impacts Key Performance Metrics

Separation Quality

Slower speeds allow for a more thorough separation. The steady, prolonged pressure ensures that the maximum amount of honey is gently pressed from the wax matrix before the wax is ejected.

Higher speeds rush this process. The wax is compacted and ejected before all the entrapped honey has a chance to escape, leading to a "wetter" end product.

Total Honey Yield

This directly correlates with separation quality. When less honey is left in the discarded wax cappings, your overall honey yield increases.

Even a small percentage improvement in extraction efficiency can result in a significant amount of recovered honey over the course of a large batch.

Wax Dryness

The effectiveness of the separation is most visible in the final wax pucks or extrusions. A slow, precise process results in drier, more compact wax.

This "dry" wax is easier to handle, store, and melt down for rendering. Wet, sticky wax is a clear indicator that the extruder is running too fast for the conditions.

Understanding the Trade-offs

The Speed vs. Quality Dilemma

The primary trade-off is simple: throughput vs. yield.

Running the extruder faster processes more cappings per hour, which is tempting for large-scale operations. However, this increased throughput comes at the direct cost of leaving honey behind in the waste product.

Risk of Clogging and Jamming

Pushing the material through the extruder too quickly can increase the risk of clogging and mechanical jams.

This forces a complete shutdown of the operation to clear the blockage, negating any time saved by the higher speed and potentially damaging the equipment.

Finding the "Sweet Spot"

There is no single "best" speed. The optimal speed is a "sweet spot" that depends on the honey's viscosity, the ambient temperature, and your specific operational goals.

The goal is to find the fastest possible speed that still produces acceptably dry wax and maximizes your net efficiency, factoring in both throughput and yield.

Setting the Right Extruder Speed for Your Goal

Ultimately, your operational priority determines the correct approach. The key is to be intentional about the speed you choose.

- If your primary focus is maximizing honey yield and quality: Run the extruder at the slower end of its operational range to ensure the most complete separation possible.

- If your primary focus is maximizing throughput for a large volume: Find the fastest speed that still produces acceptably dry wax without causing clogs, accepting a minor loss in total yield for a major gain in processing time.

Mastering your extruder is about deliberately controlling its speed to strike the perfect balance between efficiency and quality for your specific goals.

Summary Table:

| Speed Setting | Impact on Honey Yield | Impact on Wax Dryness | Best For |

|---|---|---|---|

| Slower Speed | Higher Yield | Drier, Compact Wax | Maximizing quality and total honey recovery |

| Faster Speed | Lower Yield | Wetter, Stickier Wax | Maximizing throughput for large volumes |

Ready to maximize your honey extraction efficiency?

As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the durable, high-performance extruders and equipment you need to precisely control your process. Our experts can help you select the right machine to find your operation's perfect speed-to-yield balance.

Contact HONESTBEE today to discuss your needs and boost your profitability.

Visual Guide

Related Products

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

People Also Ask

- How long does it take to extract honey with an electric extractor? Cut extraction time to minutes.

- How long does an electric honey extractor take? Drastically Cut Your Harvest Time & Effort

- What are the key steps to follow when using a honey extractor? Expert Tips for a Perfect Harvest

- What are the features of a motorized honey extractor? Boost Efficiency and Precision in Your Honey Harvest

- How do automated honey extractors reduce physical strain for beekeepers? Boost Efficiency & Prevent Burnout