Immediately following pasteurization, honey is moved into a highly controlled packaging stage. Modern facilities use specialized, automated equipment to fill containers, with distinct production lines often dedicated to different end markets, such as glass jars for retail consumers and larger formats for industrial or food service use.

The choice of honey packaging is not just about the container; it is a strategic decision that balances product protection, market appeal, and logistical efficiency for a specific end-user.

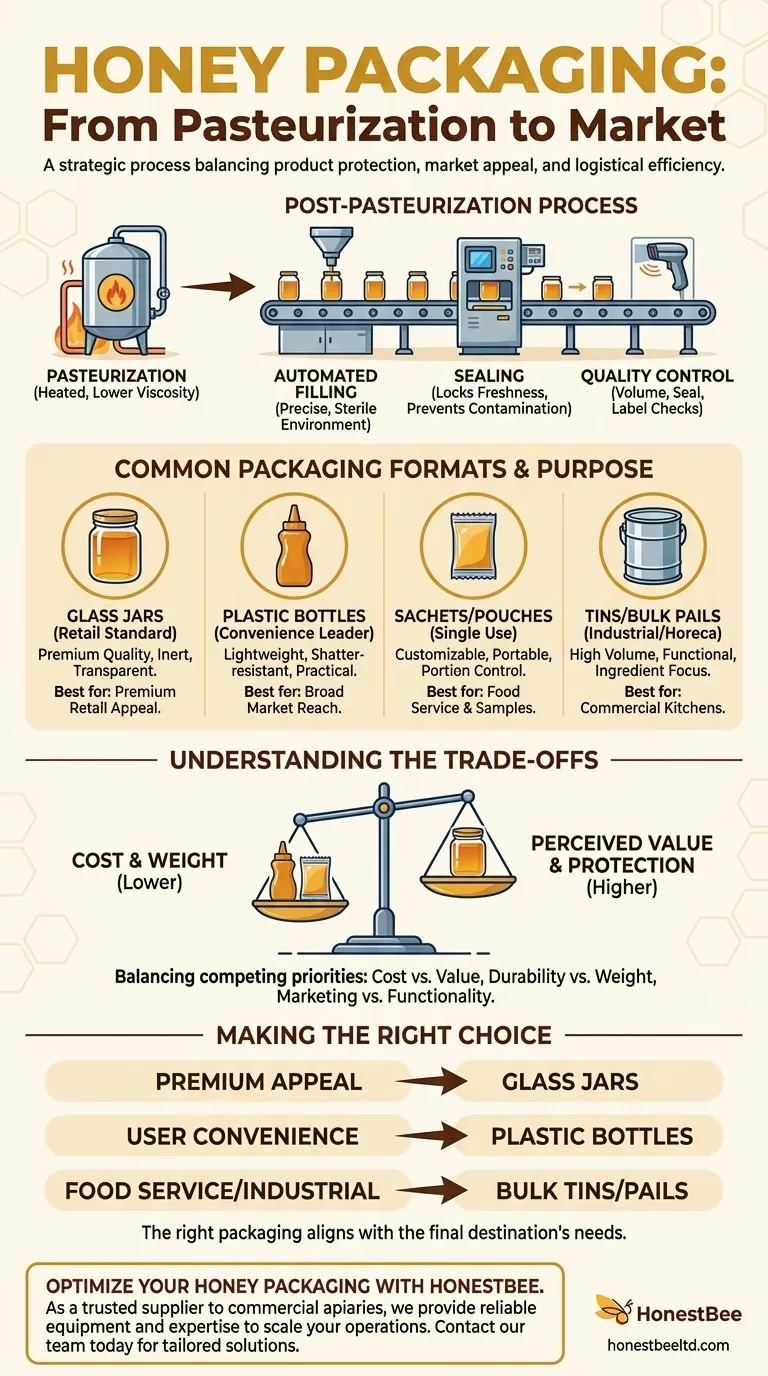

The Mechanics of Post-Pasteurization Packaging

After pasteurization, the primary goal is to package the honey quickly and safely, preserving its quality and preventing any re-contamination. This is achieved through a precise, automated process.

Automated Production Lines

Large-scale operations utilize multiple dedicated packaging lines. For example, a facility might have several lines exclusively for filling consumer-facing glass jars, while other lines are set up to handle plastic bottles, sachets, or bulk containers for commercial clients.

Maintaining Flow and Sterility

Pasteurization heats the honey, which also lowers its viscosity. The honey is often kept warm as it is transferred to the filling machines, ensuring it flows smoothly and fills containers efficiently without introducing air bubbles. The entire environment is designed to be sterile to maintain the benefits of pasteurization.

Filling, Sealing, and Quality Control

Automated fillers dispense a precise amount of honey into each container. Immediately after filling, the containers are sealed to lock in freshness and prevent contamination. This process is followed by quality checks for fill volume, seal integrity, and proper labeling.

Common Packaging Formats and Their Purpose

The type of packaging used is directly related to the honey's intended market and use case. Each material offers distinct advantages.

Glass Jars: The Standard for Quality

Glass is the classic choice for retail honey. It is inert, meaning it won't react with the honey or affect its flavor. Its transparency allows consumers to see the product's color and clarity, conveying a sense of high quality and purity.

Plastic Bottles: The Leader in Convenience

Plastic, particularly in squeezable bottle form, offers unmatched convenience for the end consumer. These containers are lightweight, shatter-resistant, and less expensive to transport, making them a highly practical choice for everyday use.

Sachets and Pouches: Designed for Single Use

Flexible pouches and small sachets are lightweight and highly customizable. They are ideal for single-serving portions in the food service industry (like restaurants and hotels), for product samples, or for on-the-go consumer products.

Tins and Bulk Pails: For Industrial and Horeca

"Horeca" (Hotels, Restaurants, Catering) and other industrial food producers buy honey as an ingredient. For this market, honey is packaged in large, functional containers like metal tins or plastic pails that prioritize volume and ease of use in a commercial kitchen.

Understanding the Trade-offs

Choosing a packaging material involves balancing competing priorities. There is no single "best" option; the right choice depends on the strategic goal.

Cost vs. Perceived Value

Glass jars are more expensive to produce and ship but create a premium image that can command a higher price. Plastic is more cost-effective but may not convey the same level of quality to all consumers.

Durability vs. Weight

Plastic's lightweight and shatterproof nature dramatically reduces shipping costs and losses from breakage. Glass is heavy and fragile but offers superior protection against oxygen and moisture over very long periods.

Marketing vs. Functionality

A uniquely shaped glass jar can be a powerful marketing tool on a crowded shelf. Conversely, a simple, squeezable plastic bottle with a no-drip cap focuses purely on user functionality and convenience.

Making the Right Choice for Your Goal

The final packaging decision should be driven by your primary objective.

- If your primary focus is premium retail appeal: Glass jars are the proven standard for showcasing honey's quality and justifying a higher price point.

- If your primary focus is user convenience and broad market reach: Squeezable plastic bottles provide the best balance of cost, safety, and ease of use for the average consumer.

- If your primary focus is the food service or industrial market: Bulk tins or pails offer the most cost-effective and practical solution for clients using honey as an ingredient.

Ultimately, the right packaging protects the integrity of the pasteurized honey while perfectly aligning with the needs of its final destination.

Summary Table:

| Packaging Format | Primary Market | Key Advantage |

|---|---|---|

| Glass Jars | Retail Consumers | Premium quality, inert, preserves flavor |

| Plastic Bottles | Broad Retail | Convenience, lightweight, cost-effective |

| Sachets/Pouches | Food Service | Single-serving, customizable, portable |

| Tins/Bulk Pails | Industrial/Horeca | High volume, functional, ingredient-focused |

Optimize Your Honey Packaging with HONESTBEE

As a trusted supplier of beekeeping supplies and equipment to commercial apiaries and distributors, HONESTBEE understands that efficient, high-quality packaging is critical to preserving your product's value. Whether you need durable containers for bulk shipping or retail-ready solutions, we provide the reliable equipment and expertise to scale your operations.

Contact our team today to discuss packaging solutions tailored to your commercial or distribution needs!

Visual Guide

Related Products

- Hexagonal Glass Honey Jars with Metal Lug Caps Elegant Versatile Packaging

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

- Classic Honey Bear Jars with Flip Top Dispensing Cap for Liquid Sweeteners

- Premium Diamond-Faceted Glass Honey Dispenser

- Honeycomb Style Drip Free Honey Dispenser

People Also Ask

- How does a piston filling machine work for honey packaging? Achieve Precise, Drip-Free Filling

- Why is sachet packaging frequently utilized for honey distribution in institutional nutrition programs? Key Benefits

- What are the advantages of using industrial honey-filling machines over manual processing? Preserving Product Efficacy

- Why exclude container weight in honey filling? Master Net Mass Accuracy with Industrial Machinery

- What are the benefits of using high-precision honey-filling machines? Boost Quality and Efficiency in Honey Packaging

- How do automated honey-filling machines contribute to the market value of honey? Enhance Your Brand and Profit Margins

- Why is advanced Honey Packaging Technology essential for commercial honey? Secure Quality and Brand Value

- How do automatic honey filling and packaging machines impact branding? Scale Your Business for Global Markets