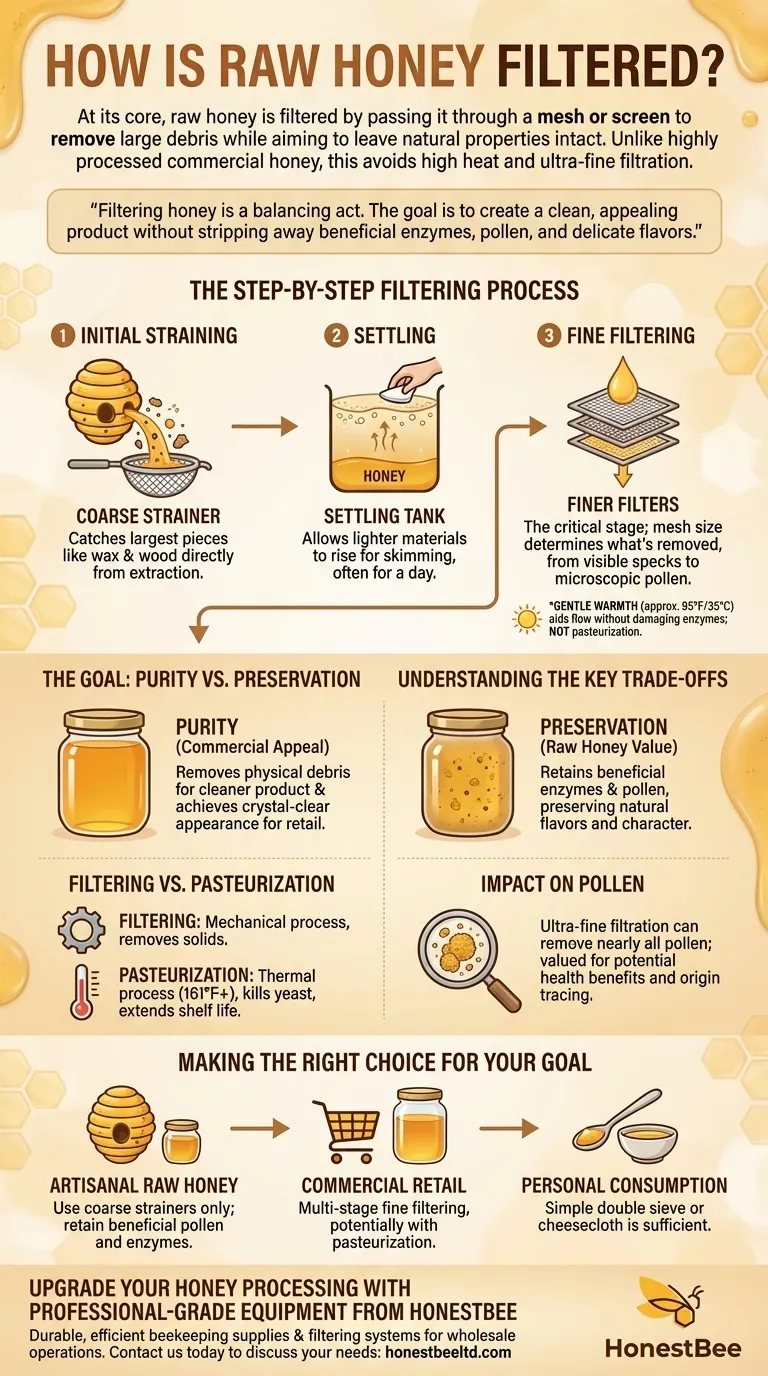

At its core, raw honey is filtered by passing it through a mesh or screen. This simple mechanical process is designed to remove large physical debris—such as beeswax, propolis, and other particles from the hive—while aiming to leave the honey's natural properties intact. Unlike highly processed commercial honey, this method avoids high heat and ultra-fine filtration that can alter the honey's fundamental character.

Filtering honey is a balancing act. The goal is to create a clean, appealing product by removing unwanted hive debris without stripping away the beneficial enzymes, pollen, and delicate flavors that define raw honey.

The Goal of Filtering: Purity vs. Preservation

The decision to filter honey, and how aggressively to do so, is driven by a conflict between achieving commercial purity and preserving the honey's natural state.

Removing Physical Debris

The primary purpose of filtering is to create a cleaner product. During extraction, it's inevitable that bits of beeswax, propolis (a resinous bee glue), and even parts of bees will mix with the honey. Filtering removes these impurities for a more palatable final product.

The Appeal of Clarity

For many consumers, crystal-clear honey is a sign of quality. Filtering helps achieve this transparent, golden appearance, which is often a key factor in a retail setting. A clear product is visually appealing and signals that it is free from foreign matter.

Preserving Natural Components

Proponents of raw honey aim to preserve its natural components. This includes beneficial enzymes, which can be damaged by heat, and trace amounts of pollen. Minimal, gentle filtering helps retain these elements, which are considered a key part of raw honey's value.

The Step-by-Step Filtering Process

Filtering is just one step in the larger honey processing workflow, which begins with harvesting frames from the hive and ends with bottling.

Step 1: Initial Straining

Immediately after honey is extracted from the comb, it's often passed through a coarse strainer. This is typically a wide-mesh metal or nylon screen that catches the largest pieces of debris, like chunks of wax or wood from the frame.

Step 2: Settling

Some beekeepers let the honey sit in a tank for a day or more after the initial strain. During this time, lighter materials like fine wax particles and air bubbles will naturally rise to the top, where they can be skimmed off.

Step 3: Fine Filtering

For a cleaner product, the honey is then passed through one or more finer filters. This is the most critical stage. The mesh size determines what is removed and what remains. A standard filter might remove most visible specks, while an ultra-fine filter can strip out even microscopic pollen grains.

The Role of Gentle Warmth

Honey is highly viscous and can be difficult to filter when cool. To aid the process, some processors gently warm the honey, but this is not pasteurization. This slight warming, often just to hive temperature (around 95°F or 35°C), makes the honey flow more easily through the filter without damaging its natural enzymes.

Understanding the Key Trade-offs

The term "filtered" can be misleading. The critical distinction lies in the intensity of the process and whether heat is applied.

Filtering vs. Pasteurization

These are two distinct processes that are often confused.

- Filtering is a mechanical process that removes solids.

- Pasteurization is a thermal process that involves heating honey to high temperatures (typically 161°F / 72°C or higher) to kill yeast cells, which prevents fermentation and extends shelf life.

Intense commercial filtering is often combined with pasteurization for maximum clarity and stability, but this is not characteristic of raw honey production.

The Impact on Pollen

Pollen is a natural component of honey and is often valued by consumers for its potential health benefits and ability to trace the honey's floral and geographic origin. Ultra-fine filtration, a process used in many large-scale commercial operations, can remove nearly all pollen from the honey.

Equipment and Maintenance

For beekeepers, proper equipment care is crucial for quality. All filtering components—tanks, pipes, and screens—must be washed with warm water and a mild detergent after use. Thoroughly drying all parts prevents corrosion and residue buildup, ensuring the system functions efficiently.

Making the Right Choice for Your Goal

The "best" filtering method depends entirely on the desired outcome for the honey.

- If your primary focus is artisanal raw honey: Use only coarse strainers to remove large debris, ensuring beneficial pollen and enzymes are fully retained.

- If your primary focus is maximum clarity for commercial retail: A multi-stage process with finer filters, potentially combined with pasteurization, is the standard approach.

- If your primary focus is personal consumption: A simple pass through a double sieve or cheesecloth is often sufficient to produce clean, delicious honey for your own use.

Ultimately, understanding the filtering process empowers you to make a conscious choice about the type of honey you produce or purchase.

Summary Table:

| Filtering Stage | Purpose | Typical Equipment |

|---|---|---|

| Initial Straining | Remove large debris (wax, wood) | Coarse metal/nylon screen |

| Settling | Allow fine particles to rise | Settling tank |

| Fine Filtering | Achieve clarity, remove specks | Fine mesh filters |

| Gentle Warming (Optional) | Improve honey flow | Temperature-controlled tank |

Upgrade Your Honey Processing with Professional-Grade Equipment from HONESTBEE

Whether you're a commercial apiary focused on artisanal raw honey or a distributor supplying retailers with crystal-clear products, the right filtering equipment makes all the difference. HONESTBEE supplies durable, efficient beekeeping supplies and equipment designed for wholesale operations. Our filtering systems help you maintain honey quality while scaling your production.

Contact us today to discuss your specific needs and discover how our solutions can enhance your honey processing workflow.

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Professional Stainless Steel Honey Filter with Support Handle

- Two-Stage Plastic Honey Filter for Buckets

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

People Also Ask

- Why is filtering honey an important step in honey processing? Ensure Purity, Clarity & Marketability

- Why is it important to inspect and replace filters in honey filtering equipment? Protect Your Honey Quality & Equipment

- What does the level of water-insoluble solids in honey indicate? Measure Filtration and Processing Efficiency

- Why is precision filtration equipment essential in black honey processing? Achieve Premium Quality & Clarity

- Why are squeezing and multi-layer filtration systems necessary for processing honey from wild sources like Apis dorsata?

- How does the use of food-grade fine filtration equipment affect the color and clarity of processed honey? Master Purity

- What are the functions of professional filtration equipment in stingless bee honey processing? Ensure Purity & Quality

- What is the industrial significance of high-precision honey filtration? Elevate Purity and Value for Dark Honey.