The primary method for removing honey from uncapped frames is through centrifugal force using a device called a honey extractor. This machine, often called a spinner, spins the frames at a high speed, forcing the honey out of the hexagonal wax cells where it can be collected. The process is designed to be efficient and to preserve the delicate honeycomb structure for the bees to reuse.

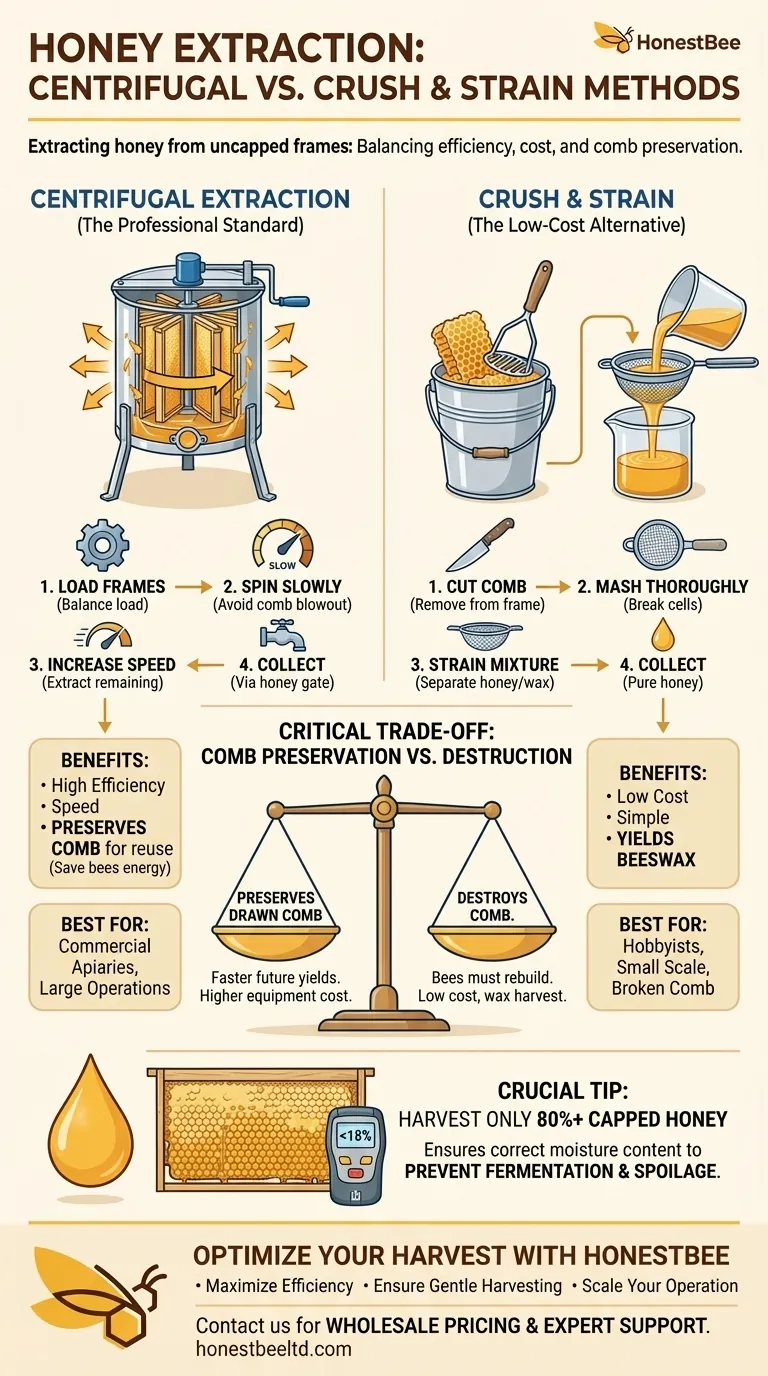

At its core, honey extraction is a choice between mechanical efficiency and manual simplicity. While a centrifugal extractor is the standard for preserving comb and processing large quantities, the simpler "crush and strain" method is a viable, low-cost alternative, especially for hobbyists.

The Principle of Centrifugal Extraction

The most common method for honey harvesting relies on a simple principle of physics. By spinning the frames, the honey, which is dense and liquid, is flung outward against the wall of the extractor drum.

How a Honey Extractor Works

An extractor is essentially a large drum, typically made of stainless steel, with a basket inside that holds the honey frames. A crank or an electric motor rotates this basket.

Think of it like a salad spinner. As the basket spins, the honey is forced out of the open cells and splatters against the inner wall of the drum. It then slides down the wall and pools at the bottom.

A spigot, or honey gate, at the bottom of the extractor allows you to drain the collected honey into a bucket for filtering and bottling.

The Step-by-Step Extraction Process

-

Load the Frames: Place your uncapped frames vertically into the slots of the extractor basket. Try to balance the load by placing frames of similar weight opposite each other.

-

Begin Spinning Slowly: Start cranking or turn the motor on at a very low speed. This is critical, especially with new or foundationless frames, as spinning too fast initially can cause the fragile wax comb to "blow out" and be destroyed by the weight of the honey.

-

Increase the Speed: Once some of the honey has been extracted and the frames are lighter, you can gradually increase the speed to remove the remaining honey.

-

Flip and Repeat (If Necessary): Some extractors (tangential models) only extract honey from one side of the frame at a time. If you have one of these, you'll need to spin out about half the honey, flip each frame to face the other way, extract that side completely, then flip them back one last time to finish the first side. More advanced radial extractors spin honey from both sides simultaneously.

An Alternative: The Crush and Strain Method

For beekeepers with only one or two hives, or for those dealing with delicate foundationless comb, a mechanical extractor may not be practical. The crush and strain method is a perfectly effective, low-tech alternative.

When to Choose Crush and Strain

This method is ideal if you are a small-scale hobbyist, if your comb is not built on a sturdy foundation, or if a piece of comb has broken. It requires no expensive equipment.

How It Works

The process involves cutting the entire honeycomb out of the frame and placing it into a large, food-grade bucket. The comb is then mashed up using a tool like a potato masher, which breaks open all the wax cells.

The resulting mixture of honey and wax is then poured through a series of strainers or cheesecloth to separate the pure honey from the solid beeswax particles.

Understanding the Trade-offs

Choosing a method is about balancing efficiency, cost, and your beekeeping goals. There is no single "best" way; there is only the best way for your specific situation.

Extraction: Speed and Reusability

The primary advantage of using an extractor is that it preserves the drawn comb. The frames can be returned to the hive, giving the bees a massive head start for the next honey flow. This saves the bees an enormous amount of energy, as producing wax is very resource-intensive. Extractors are fast and clean, making them ideal for larger apiaries. The main drawback is the significant cost and storage space required for the equipment.

Crush and Strain: Simplicity and Wax Harvest

The crush and strain method is inexpensive and simple, requiring only basic kitchen equipment. A major benefit is that you are left with all the beeswax, which is a valuable product in its own right. The significant downside is that the comb is destroyed. Your bees must work to completely rebuild every cell before they can store more honey, which can impact your hive's total honey production.

A Critical Note on Honey Readiness

Regardless of the method you choose, only harvest frames that are at least 80% capped. Capped honey, covered with a white waxy layer, has been dehydrated by the bees to the correct moisture content (~18%). Extracting "unripe" or uncapped honey with higher moisture content will result in a harvest that ferments and spoils.

Choosing the Right Extraction Method for Your Apiary

Your choice should be guided by the scale of your operation and your long-term goals.

- If your primary focus is efficiency and a large honey yield: An electric extractor is the best investment because it allows you to process many frames quickly while preserving the comb for reuse.

- If you are a hobbyist with a few hives: A manual hand-crank extractor offers a good balance of cost and comb preservation, but the crush and strain method is perfectly adequate and highly cost-effective.

- If you use foundationless frames or have broken comb: The crush and strain method is often the safest and most practical choice to avoid destroying delicate combs in a high-speed extractor.

Ultimately, selecting the right technique is about aligning your equipment and process with your personal beekeeping philosophy.

Summary Table:

| Method | Best For | Key Advantage | Key Consideration |

|---|---|---|---|

| Centrifugal Extractor | Commercial apiaries, larger operations | Preserves comb for bee reuse; high efficiency | Higher initial equipment cost and storage needs |

| Crush and Strain | Hobbyists, small-scale beekeepers, broken comb | Low cost, simple; yields pure beeswax | Destroys comb; bees must rebuild, impacting yield |

Ready to Optimize Your Honey Harvest?

Whether you're a commercial apiary scaling up or a distributor supplying the beekeeping community, having the right equipment is key to a successful harvest. HONESTBEE supplies professional-grade honey extractors and essential beekeeping supplies through our wholesale-focused operations.

We help you:

- Maximize Efficiency: Process large quantities of honey quickly while preserving valuable comb.

- Ensure Gentle Harvesting: Our equipment is designed to protect delicate frames and maximize honey yield.

- Scale Your Operation: Get the reliable, durable tools you need for a productive season.

Let's discuss the best extraction solution for your needs. Contact HONESTBEE today for wholesale pricing and expert support.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- What are the core functions of an industrial 12-frame honey extractor? Boost Efficiency and Hive Resource Conservation

- How many frames can different types of honey extractors hold? Maximize Your Harvest Efficiency

- What are the main types of honey extractors available? A Guide to Choosing the Right Model

- What is the value of professional honey harvesting and weighing equipment? Optimize Your Queen Rearing Data

- What is the technical function of an extraction basket in traditional honey processing? Master Natural Honey Filtration

- Why is precise speed control critical for centrifugal honey extractors? Maximize Yields and Protect Your Honeycombs

- What are the characteristics of diesel-powered honey extractors? High Torque Solutions for Off-Grid Operations

- What are the benefits of using honey extractors for beekeepers? Boost Efficiency & Honey Quality