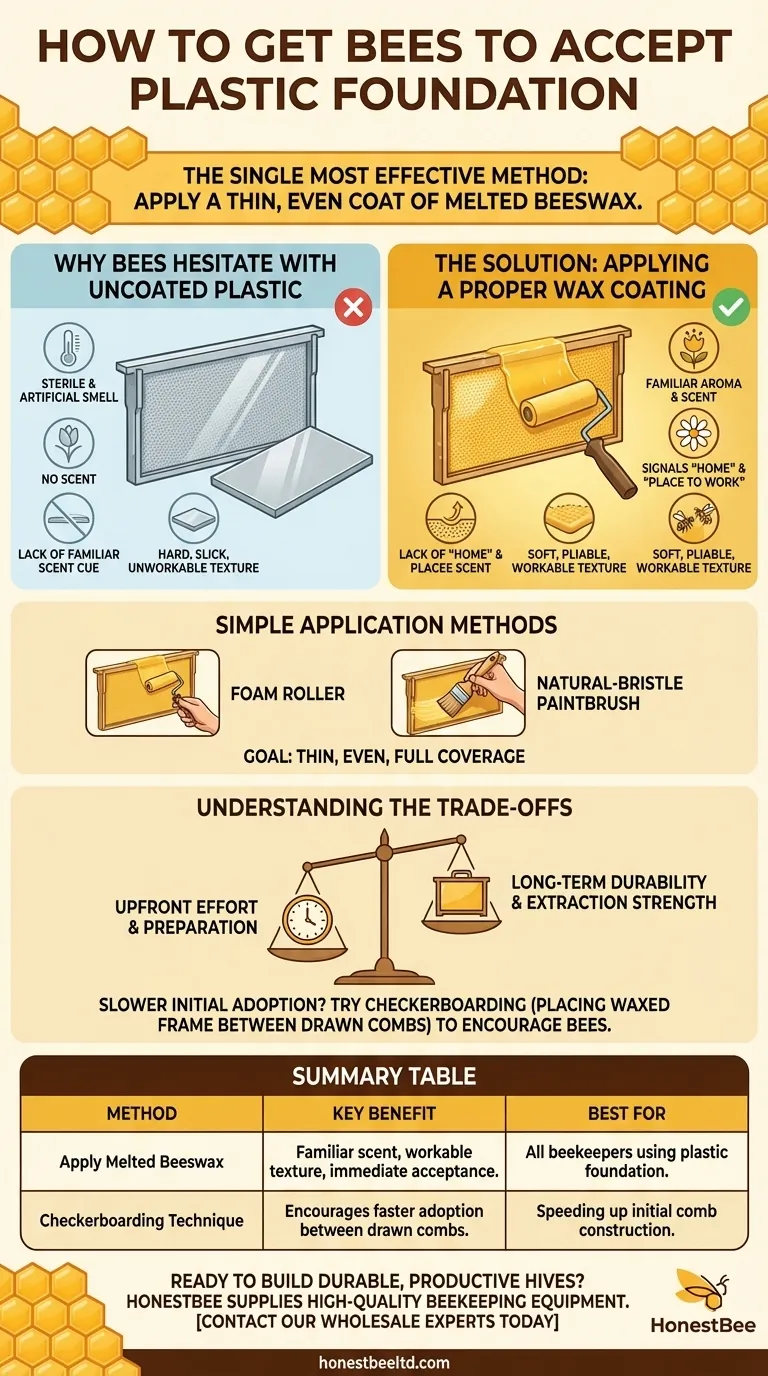

The single most effective method to get bees to accept plastic foundation is to apply a thin, even coat of melted beeswax. Bees are instinctively driven by scent and texture, and the foreign nature of uncoated plastic is often a deterrent for them. By adding a layer of familiar beeswax, you provide the crucial sensory cues they need to begin their work.

Bees operate on instinct, driven by scent and texture. Uncoated plastic is a foreign object they will often ignore. By applying a layer of real beeswax, you provide the familiar aroma and workable surface they need to recognize the foundation as a place to build comb.

Why Bees Hesitate with Uncoated Plastic

To solve this problem, we first need to understand the bees' perspective. A beehive is a finely tuned environment governed by chemical signals and natural materials.

The Critical Importance of Scent

Bees communicate and operate within a world of pheromones and familiar smells. Pure beeswax has a distinct, attractive aroma that signals "home" and "a place to work."

Plastic, on the other hand, is sterile and smells artificial. This lack of a familiar scent cue means bees often treat it as an unworkable, foreign wall within their hive.

The Need for a Workable Texture

Bees don't just build on a flat surface; they manipulate the wax, adding to the embossed cell pattern to draw it out.

The hard, slick surface of raw plastic offers no purchase and is difficult for them to manipulate. A thin layer of beeswax gives them a soft, pliable material to immediately begin working.

The Solution: Applying a Proper Wax Coating

The reference is clear: applying wax is the key. Even foundations that come "pre-waxed" from the factory can benefit from a fresh coat.

Why an Extra Coat Matters

Factory wax coatings can be extremely thin, inconsistent, or may have lost their scent during storage and shipping.

A fresh coat of clean, melted beeswax restores that powerful, attractive aroma that encourages bees to investigate and start building.

Simple Application Methods

You do not need complex equipment. The most common method is using a small foam roller or a natural-bristle paintbrush.

Simply dip the roller or brush in melted beeswax and apply a thin, even layer across the entire surface of the plastic foundation. The goal is full coverage, not a thick, drippy coat.

Understanding the Trade-offs

While effective, using plastic foundation involves balancing benefits and drawbacks. Understanding them allows you to make an informed decision.

Upfront Effort vs. Long-Term Durability

The primary trade-off is your time. Waxing frames is an extra step that requires preparation and effort.

However, the benefit is a much more durable frame that can withstand the force of honey extraction and last for many seasons, unlike delicate pure wax foundation which can easily be damaged.

Slower Initial Adoption

Even when properly waxed, a colony may sometimes take slightly longer to start working on plastic foundation compared to pure beeswax, especially if they have other options available.

Placing a waxed plastic frame between two already drawn-out combs (a technique called "checkerboarding") can significantly encourage bees to start working on it faster.

Making the Right Choice for Your Hive

Your decision should be guided by your specific beekeeping goals.

- If your primary focus is the fastest possible comb construction: Apply a fresh, generous coat of beeswax to your plastic foundation to make it as attractive as possible to the bees.

- If your primary focus is long-term durability and ease of honey extraction: Plastic foundation is an excellent choice, but be prepared for the necessary time investment of waxing it properly to guarantee acceptance.

Properly preparing your foundation respects the bees' natural instincts and sets your hive up for a productive season.

Summary Table:

| Method | Key Benefit | Best For |

|---|---|---|

| Apply Melted Beeswax | Provides familiar scent and workable texture for immediate bee acceptance. | All beekeepers using plastic foundation. |

| Checkerboarding Technique | Encourages faster adoption by placing waxed frame between drawn combs. | Speeding up initial comb construction. |

Ready to build durable, productive hives? Properly prepared plastic foundation is key for commercial apiaries and distributors seeking long-lasting, easy-to-extract frames. HONESTBEE supplies the high-quality beekeeping equipment and supplies you need for success. Contact our wholesale experts today to discuss your needs!

Visual Guide

Related Products

- Food Grade Plastic bee Foundation for Bee Frames

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- HONESTBEE Pneumatic Dual Wire Embedder for W-Pattern Foundation Wiring

People Also Ask

- What is the purpose of using pre-installed plastic foundations? Boost Beekeeping Research & Commercial Efficiency

- What are the advantages of using plastic foundation in hives? Boost Apiary Efficiency & Durability

- What are the pros and cons of using plastic foundation? Balance Durability and Bee Acceptance

- Why are plastic frames popular in commercial beekeeping? Boost Efficiency & Durability at Scale

- When is it advantageous to use plastic foundation in beehive frames? Enhance Durability and Extraction Efficiency

- Why are plastic frames considered a better long-term investment for beekeepers with many hives? Maximize Efficiency & Durability

- What are the benefits of coating a plastic foundation with beeswax? Boost Acceptance and Hive Health

- What methods can be used to coat plastic foundation sheets with beeswax? Optimize Your Hive Acceptance