In short, a honey vacuum thickener offers significant advantages in operational efficiency, cost-effectiveness, and product quality. The equipment is specifically designed for small to medium-sized honey producers who need a reliable method to improve honey concentration without compromising its natural characteristics.

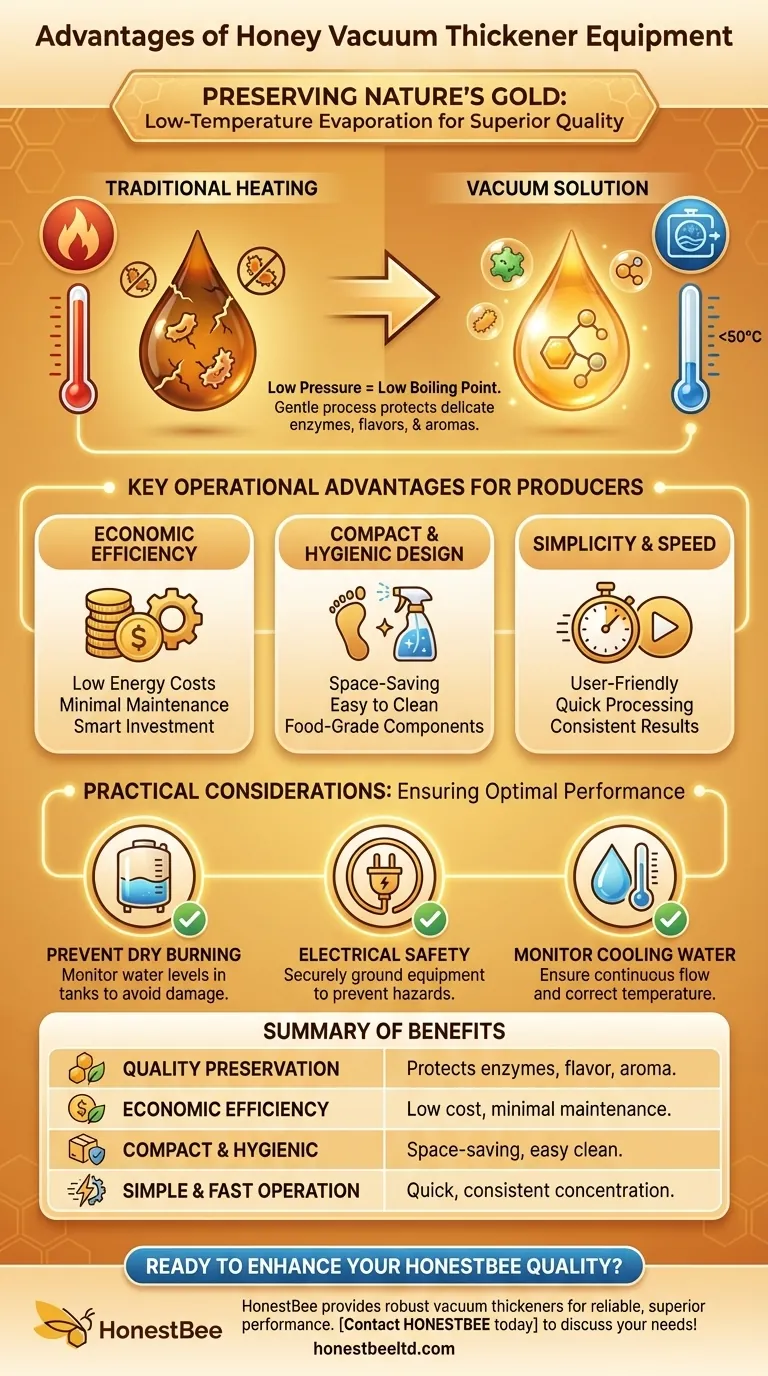

The core value of a honey vacuum thickener lies in its ability to remove excess water at a low temperature. This preserves the honey's delicate enzymes, flavors, and aromas, which are often damaged by traditional heating methods, resulting in a higher-quality, shelf-stable final product.

How Vacuum Concentration Protects Honey Quality

To understand the equipment's benefits, we must first understand the fundamental challenge of processing honey. Honey with high water content is prone to fermentation and has a shorter shelf life.

The Problem with Traditional Heating

Traditionally, excess water is removed by heating the honey to evaporate the moisture. However, high temperatures can degrade the honey's quality, destroying beneficial enzymes and altering its delicate flavor profile.

The Vacuum Solution: Low-Temperature Evaporation

A honey vacuum thickener solves this problem by using a simple principle of physics: water's boiling point decreases as pressure drops.

By creating a vacuum, the equipment allows water to evaporate from the honey at a much lower temperature than its normal boiling point. This gentle process removes moisture efficiently while keeping the honey's natural composition intact.

Key Operational Advantages for Producers

For small and medium-sized enterprises, the practical benefits of this technology translate directly to the bottom line and the quality of the final product.

Economic Efficiency

The system is designed for economical operation. It boasts minimal energy costs, low initial investment, and low maintenance expenses, making it an accessible technology for growing businesses.

Compact and Hygienic Design

With a compact footprint, the equipment is suitable for facilities where space is a premium. Its design also prioritizes hygiene, ensuring components are easy to clean and maintain, which is critical for food-grade processing.

Simplicity and Speed

The equipment is noted for its simple operation and high efficiency. It allows producers to process honey quickly, saving valuable time and labor while achieving consistent results.

Understanding the Practical Considerations

While highly effective, operating a honey vacuum thickener requires attention to detail to ensure safety and optimal performance. These are not disadvantages, but necessary operational procedures.

Preventing Dry Burning

The operator must constantly monitor the water level in the preheating and concentration tanks. Allowing the tanks to run dry can damage the heating elements and the equipment itself.

Ensuring Electrical Safety

Proper safety protocols are paramount. The equipment's outer shell must be securely grounded to prevent the risk of electrical shock or hazards during operation.

Monitoring Cooling Water

During the concentration process, the condenser requires a flow of cooling water to function. The temperature of this water must be monitored to ensure the system is operating efficiently.

Is a Vacuum Thickener Right for Your Operation?

Choosing the right equipment depends entirely on your specific goals, budget, and scale. A honey vacuum thickener is an excellent investment, but only when it aligns with your operational needs.

- If your primary focus is preserving artisanal quality: The low-temperature processing is the single most important feature for protecting the unique flavor and enzymatic properties of your honey.

- If your primary focus is operational efficiency for an SME: The combination of low cost, simple operation, and fast processing makes this equipment a strong choice for scaling production without a massive investment.

- If your primary focus is creating a standardized, shelf-stable product: This machine provides a reliable method for achieving the ideal water content, ensuring product consistency and preventing fermentation.

Ultimately, this equipment empowers producers to create a superior and more stable product efficiently and affordably.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Quality Preservation | Low-temperature evaporation protects honey's natural enzymes, flavor, and aroma. |

| Economic Efficiency | Low energy costs, minimal maintenance, and affordable initial investment. |

| Compact & Hygienic | Space-saving design with easy-to-clean, food-grade components. |

| Simple & Fast Operation | User-friendly system for quick, consistent honey concentration. |

Ready to enhance your honey's quality and your operation's efficiency?

As a trusted supplier for commercial apiaries and beekeeping equipment distributors, HONESTBEE provides robust honey vacuum thickeners designed for reliability and superior performance. Our equipment helps you achieve a stable, high-quality product while optimizing your production costs.

Contact HONESTBEE today to discuss your needs and discover the right solution for your business!

Visual Guide

Related Products

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

People Also Ask

- What are the generally recommended drying conditions for honey? Maintain Quality with Optimal Heat and Moisture

- What is the technical purpose of moisture control and heating in honey? Master Post-Harvest Quality and Stability

- What is the primary function of professional dehumidification equipment in honey processing? Stability & Quality

- How does the internal ventilation management of a beehive affect the efficiency of honey dehydration?

- How does industrial honey filtering and dehydration equipment improve product quality? Boost Your Commercial Honey Yield