In practice, honey mixer capacities are not standardized and vary significantly based on the manufacturer and intended operational scale. While specific liter or kilogram options differ between suppliers, they generally fall into categories ranging from small tabletop units for hobbyists to large industrial vats for commercial processors.

The most critical factor is not the specific capacity number itself, but how that capacity aligns with your batch size, workflow, and operational goals. Choosing the correct size is a balance between processing efficiency and preserving the quality of your honey.

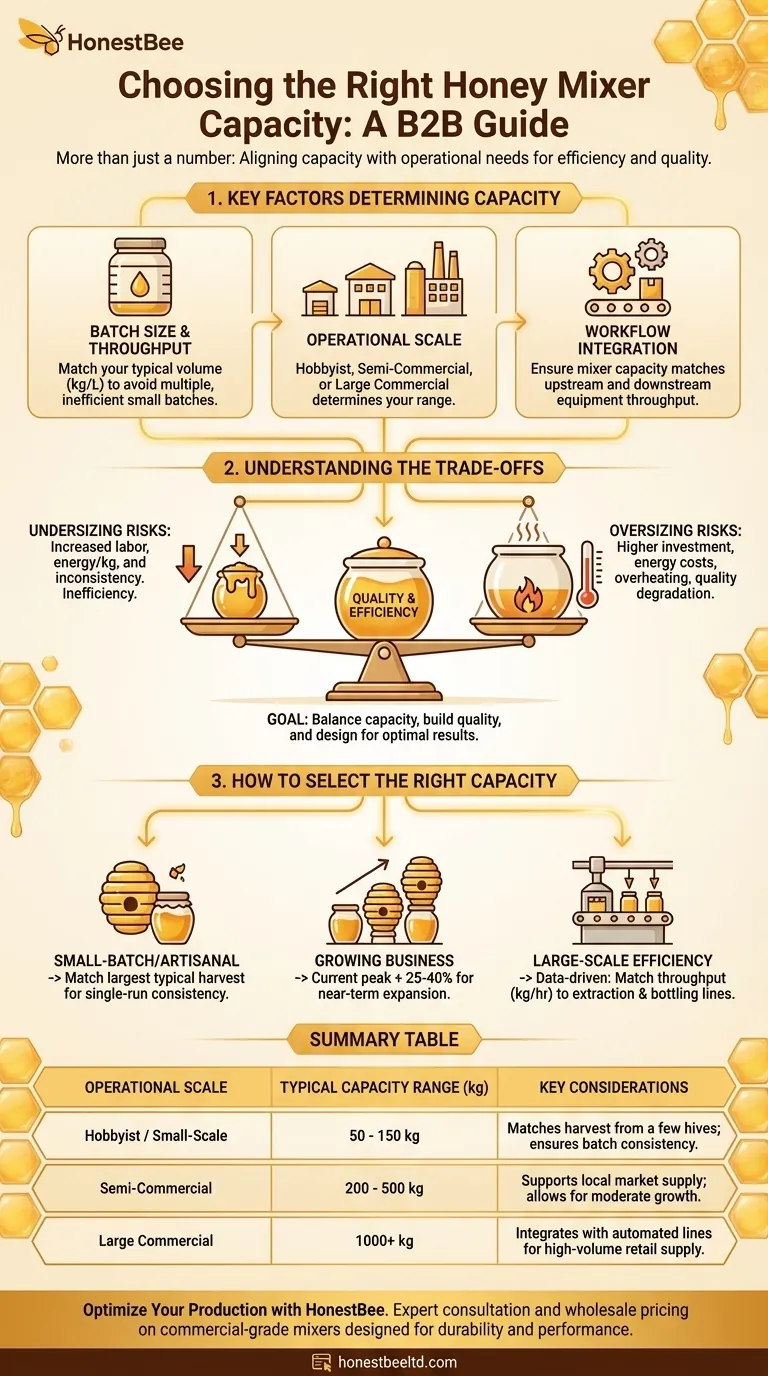

Key Factors That Determine Your Required Capacity

To select the right mixer, you must first analyze your production needs. The ideal capacity is a direct function of your operational realities.

Batch Size and Throughput

Your primary consideration is the volume of honey you process at one time. This is often dictated by the output of your extractors or the size of your settling tanks.

Measure your typical or maximum batch in kilograms or liters. The mixer's capacity should comfortably accommodate this volume without running multiple, inefficiently small batches.

Operational Scale: Hobbyist to Commercial

The appropriate capacity is directly tied to the scale of your operation.

- Hobbyist/Small-Scale: Typically processes honey from a few hives. Capacities in the range of 50 to 150 kg (approx. 35 to 105 liters) are common.

- Semi-Commercial: A growing business that supplies local markets. These users often require mixers from 200 to 500 kg (approx. 140 to 350 liters).

- Large Commercial: Industrial-scale processors supplying major retailers. These operations use vats that can hold 1000 kg or more, often integrated into a fully automated line.

Workflow Integration

Consider how the mixer fits into your entire production chain. A mixer that is too large can create a bottleneck if your bottling equipment is slow, leaving honey heated for extended periods.

Conversely, a mixer that is too small will starve a high-speed bottling line, forcing frequent and costly downtime. The capacity must be matched to the throughput of the steps before and after it.

Understanding the Trade-offs

Choosing a capacity is not just about matching your batch size; it involves balancing initial cost, operating expense, and potential risks to your product.

The Pitfall of Undersizing

Opting for a mixer that is too small leads to significant operational inefficiencies. You will be forced to run multiple batches, which increases labor costs, energy consumption per kilogram, and the risk of inconsistency between batches.

The Hidden Costs of Oversizing

A mixer that is too large is not a "future-proof" solution; it is a liability. You face a higher upfront investment and increased energy costs to heat a larger volume (or surface area) than necessary.

Most importantly, processing a small batch in a huge tank can lead to overheating, as the heating elements are designed for a full load. This can raise HMF levels and degrade the quality of your honey.

Build Quality vs. Pure Capacity

Do not fixate solely on the capacity number. A well-constructed 200 kg mixer with an efficient heating jacket and a properly designed mixing blade is far superior to a poorly made 300 kg mixer that heats unevenly or is difficult to clean. Prioritize build quality, material (e.g., 304 stainless steel), and design.

How to Select the Right Capacity

Base your decision on a clear-eyed assessment of your current and near-future needs.

- If your primary focus is small-batch, artisanal production: Choose a capacity that matches your largest typical harvest to ensure consistency in a single run.

- If your primary focus is growing your business: Select a mixer that can handle your current peak batch size with an additional 25-40% capacity to accommodate near-term growth without over-investing.

- If your primary focus is large-scale commercial efficiency: Your decision must be driven by data, matching the mixer's throughput (kg/hour) directly to the capacity of your extraction and bottling lines.

Ultimately, the right mixer is the one that streamlines your workflow, protects the delicate quality of your honey, and provides a reliable return on your investment.

Summary Table:

| Operational Scale | Typical Capacity Range (kg) | Key Considerations |

|---|---|---|

| Hobbyist / Small-Scale | 50 - 150 kg | Matches harvest from a few hives; ensures batch consistency. |

| Semi-Commercial | 200 - 500 kg | Supports local market supply; allows for moderate growth. |

| Large Commercial | 1000+ kg | Integrates with automated lines for high-volume retail supply. |

Optimize Your Honey Production with the Perfectly Sized Mixer

Choosing the right honey mixer capacity is critical for your operational efficiency and the final quality of your product. At HONESTBEE, we specialize in supplying durable, high-performance beekeeping equipment to commercial apiaries and distributors. Our range of honey mixers is designed with the precise needs of professional beekeepers in mind, ensuring even heating, easy cleaning, and reliable performance batch after batch.

Let our experts help you analyze your workflow and select a mixer that perfectly balances your batch size, throughput, and growth plans. Avoid the pitfalls of undersizing or oversizing—invest in equipment that delivers a clear return.

Contact HONESTBEE today for a personalized consultation and wholesale pricing on commercial-grade honey mixers.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- 10L Stainless Steel Electric Honey Press Machine

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- Why is high-precision extraction and mixing equipment critical? Unlock 400x Value in Pharmaceutical Honey

- How does the integration of additives like nuts or chocolate into honey affect market value? Maximize Your Profit

- Why is high-precision mixing and filling equipment necessary for composite honey? Ensure Product Stability & Quality

- What is the function of an industrial-grade electric mixer in beekeeping pest control? Master Botanical Extraction

- Why is a constant temperature stirring device necessary for the thermal processing of honey-apple jam? Expert Insights

- Why are specialized mixers required for blending bee bread with honey? Preserve Quality and Texture

- Why is specialized honey emulsification or stirring equipment utilized to produce cream honey? Elevate Your Honey Value

- What are the technical benefits of homogenization during the mixing and preparation process of bee feed?