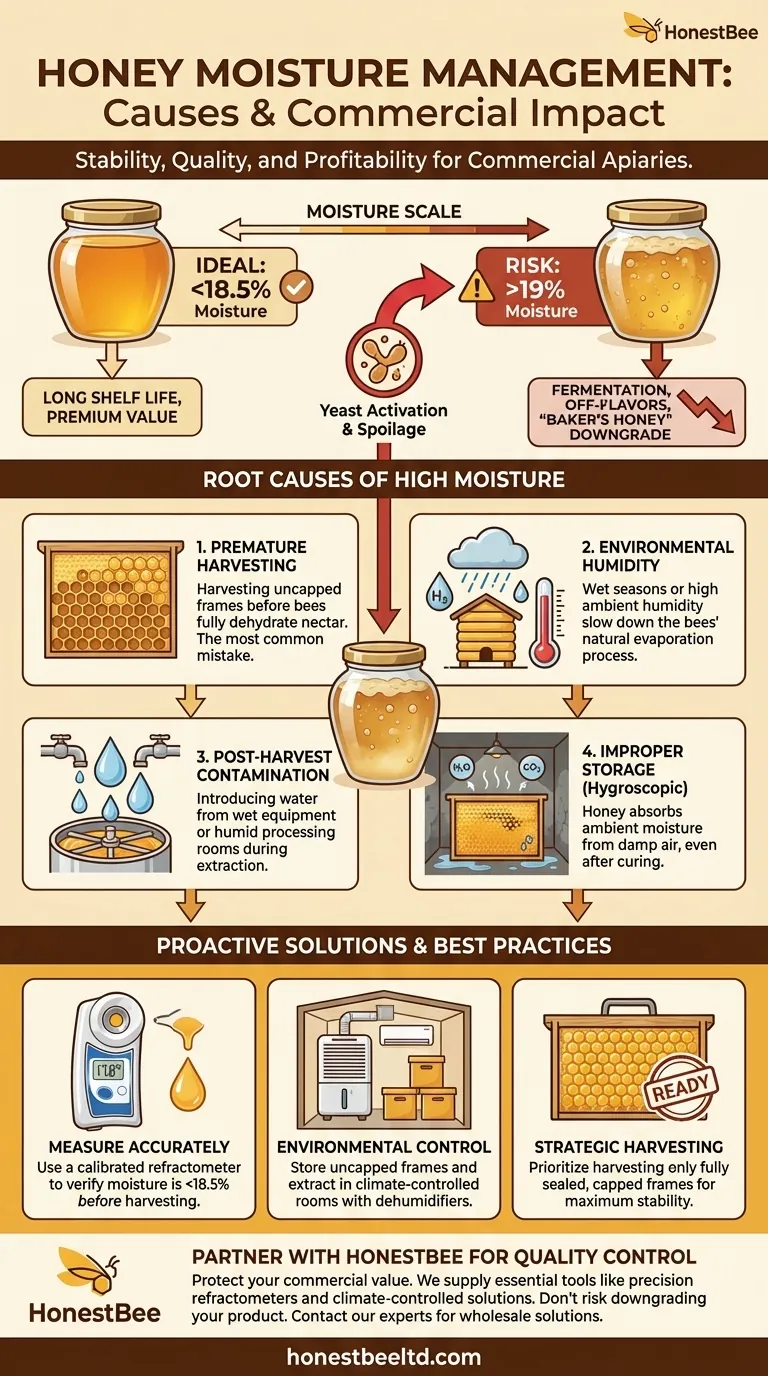

The stability and quality of your honey are directly tied to its moisture content. High moisture is primarily caused by harvesting honey before the bees have fully dehydrated it, but it can also result from environmental factors like high humidity, or procedural errors such as introducing water during extraction or storing uncapped frames improperly.

The central challenge is that honey with high moisture content—typically above 19%—is unstable. It creates a breeding ground for yeast, leading to fermentation that spoils the honey's flavor, aroma, and commercial value.

Why Moisture Content is the Critical Factor in Honey Quality

Understanding the "why" behind moisture control is the first step toward producing a superior, shelf-stable product. It is not an arbitrary metric; it is the single most important variable for honey longevity.

The Threshold for Fermentation

Honey is naturally resistant to spoilage due to its low water activity and high sugar concentration. However, when the moisture content rises above the 18-19% range, dormant osmophilic yeasts present in the honey can activate and multiply.

This yeast activity initiates fermentation, converting the honey's sugars into alcohol and carbon dioxide, resulting in a sour taste and bubbly appearance.

Impact on Flavor and Shelf Life

Properly cured honey with low moisture can last for decades, even centuries. Its flavor profile remains stable and complex.

High-moisture honey, even if it doesn't fully ferment, will have a shorter shelf life and a less concentrated flavor. It can also cause practical issues, like sticking to packaging and being difficult to dispense.

From Premium Product to "Baker's Honey"

Fermented honey is considered spoiled and is unsuitable for sale as table honey. At best, it can be downgraded to "baker's honey," a much lower-value product used in commercial baking where its off-flavors can be masked. This represents a significant financial loss for the producer.

Diagnosing the Root Causes of High Moisture

High moisture is rarely due to a single cause. It is usually a combination of environmental conditions and beekeeper decisions. Pinpointing the source is key to preventing it.

Environmental Factors: The Starting Point

Bees make honey from nectar, which can have a water content of 80% or more. Regional climate and weather play a significant role.

A wet spring or a prolonged humid season means the air itself is saturated with moisture. This makes it much harder for bees to evaporate water from the nectar, slowing down the ripening process.

Premature Harvesting: The Most Common Mistake

This is the most frequent and preventable cause. Bees perform the critical job of dehydrating the nectar inside the hive by fanning their wings to create airflow. Once the moisture level is right (typically below 18.5%), they seal the cell with a wax cap.

Harvesting frames with a high percentage of uncapped cells is a direct indicator that the honey is not "ripe" or fully cured. The bees have not finished their work, and the honey's moisture content is almost certainly too high.

Post-Harvest Contamination

Water can be introduced accidentally during the extraction and bottling process. Using wet equipment, cleaning with water without thorough drying, or working in a highly humid room can all increase the final moisture content of your honey.

Improper Storage

Honey is hygroscopic, meaning it will absorb moisture from the surrounding air. Storing uncapped frames of honey for any length of time in a damp basement or humid environment will cause the honey to draw in water, raising its moisture level even after it was perfectly cured in the hive.

Understanding the Trade-offs and Best Practices

Managing moisture isn't just about avoiding mistakes; it's about making informed decisions. The best tool for this is a honey refractometer.

The Importance of Measurement

Do not rely on guesswork or visual cues alone. A honey refractometer is an essential tool that provides an instant, accurate measurement of moisture content.

Testing honey from uncapped cells before you decide to harvest is the most effective quality control measure you can take. This simple step tells you definitively whether the honey is ready.

The Risk of Post-Harvest Correction

While you can reduce moisture after extraction using dehumidifiers or gentle warming, this comes with risks. Heating honey, in particular, can destroy its delicate enzymes and volatile aromatic compounds, degrading its quality and flavor. Prevention is always superior to correction.

A Proactive Strategy for Moisture Management

Your goal should be to ensure honey is perfect at the moment of harvest. Use the following guidelines to inform your process.

- If your primary focus is maximum quality and stability: Only harvest fully capped frames and use a refractometer to verify that moisture is below 18.5% before you begin extracting.

- If you must harvest in a humid environment: Prioritize testing uncapped cells and consider leaving frames on the hive longer; if you must pull them, immediately store them in a climate-controlled room with a dehumidifier.

- If you suspect high moisture after extraction: Act immediately. Use a dehumidifier in a small, sealed room or a specialized honey warmer with precise, low-temperature controls to gently reduce moisture, testing frequently with a refractometer.

Ultimately, managing moisture is the defining skill that separates good beekeepers from great ones, ensuring every jar is a stable, high-quality product.

Summary Table:

| Cause of High Moisture | Key Impact on Honey |

|---|---|

| Premature Harvesting (Uncapped Frames) | High risk of fermentation, leading to spoilage and off-flavors. |

| High Environmental Humidity | Slows bee dehydration, resulting in unstable honey from the start. |

| Post-Harvest Water Contamination | Introduces moisture during extraction or bottling, raising final levels. |

| Improper Storage (Hygroscopic) | Honey absorbs ambient moisture, increasing content even after curing. |

Protect your honey's quality and commercial value with the right equipment. High moisture content is a primary cause of spoilage and financial loss for commercial apiaries. HONESTBEE supplies the essential tools—like precision honey refractometers and climate-controlled storage solutions—to help you accurately measure moisture, prevent fermentation, and ensure every batch meets premium standards. Don't let unstable honey downgrade your product to 'baker's grade.' Contact our experts today to discuss wholesale solutions for your operation.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Plastic Honey Gate Spout with Wing Nut for Beekeeping Honey Bucket

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- Why is Postharvest Drying Equipment critical in the stingless bee honey supply chain? Prevent Spoilage & Boost Quality

- What is the ease of use of the honey dryer's controller? Master Honey Drying with Intuitive Control

- What is the purpose of using industrial drying or dehydration equipment after honey extraction? Secure Honey Stability

- What is the typical humidity reduction rate of the honey dryer? Optimize Your Honey Processing Speed

- How do industrial heating and dehumidification processes control Small Hive Beetle? Expert SHB Sterilization Guide

- Why is moisture control important during honey drying? Prevent Fermentation & Ensure Quality

- What are the benefits of using a honey dryer for honey production? Boost Yield & Quality

- How does a honey dryer remove water from honey? A Guide to Hygienic, Efficient Moisture Control