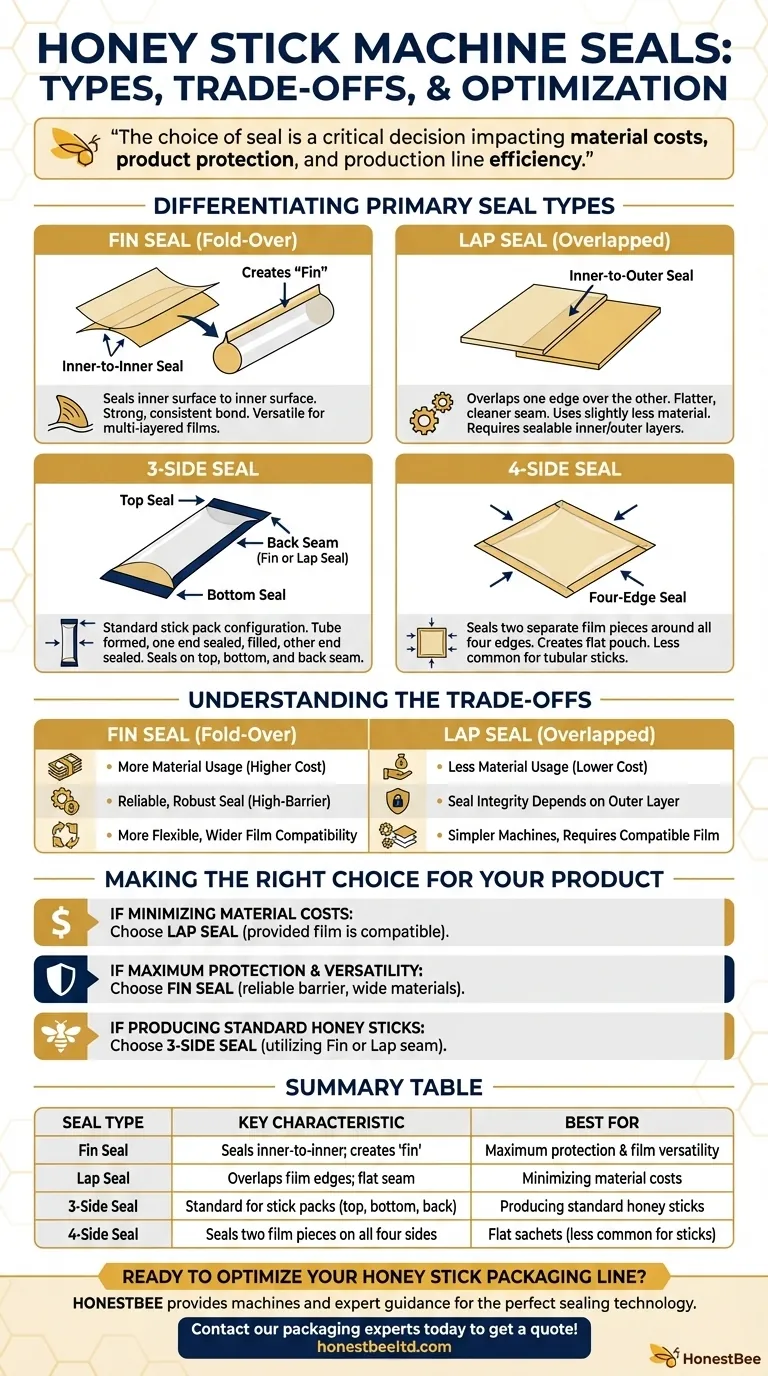

A honey stick machine primarily creates four distinct types of seals to form and secure the package. The most common configurations are the fin seal (or fold-over seal), the lap seal (or overlapped seam), the 3-side seal, and the 4-side seal, each serving a different purpose in packaging efficiency and product integrity.

The choice of seal is not merely about closing a stick pack; it is a critical decision that directly impacts material costs, the level of product protection, and the overall efficiency of your production line.

Differentiating the Primary Seal Types

Understanding how each seal is formed is key to selecting the right machine and film for your product. The primary difference lies in how the longitudinal (vertical) seam of the stick is created before the ends are sealed.

The Fin Seal (Fold-Over Seal)

A fin seal is created by bringing the two inside edges of the packaging film together and sealing them flat. This creates a small "fin" that runs along the back of the stick.

This method is highly versatile because it always seals the inner surface to the inner surface, ensuring a strong, consistent bond even with multi-layered films.

The Lap Seal (Overlapped Seam)

A lap seal is formed by overlapping one edge of the film over the other. The machine then seals the inner surface of one edge to the outer surface of the other.

This technique creates a flatter, cleaner-looking seam and uses slightly less material than a fin seal. However, it requires that the film's inner and outer layers are compatible for sealing.

The 3-Side Seal

This is the standard configuration for most stick packs, including honey sticks. The process forms a tube of film (using either a fin or lap seal for the back), seals one end, fills the stick with product, and then seals the other end.

The name refers to the finished pack having seals on three sides: the top, the bottom, and the vertical back seam.

The 4-Side Seal

Less common for stick packs, a 4-side seal creates a flat pouch by sealing two separate pieces of film together around all four edges. This is more typical for flat sachets rather than the tubular shape of a honey stick.

Understanding the Trade-offs

Choosing a seal type is an exercise in balancing cost, performance, and aesthetics. Each method comes with distinct advantages and disadvantages.

Material Consumption and Cost

The most significant difference between fin and lap seals is material usage. Because a lap seal overlaps the film, it requires less material per stick than a fin seal, which can lead to considerable cost savings at high production volumes.

Seal Integrity and Barrier Properties

A fin seal generally provides a more reliable and robust seal. Since it fuses the sealant layers (inner-to-inner), it's often the preferred choice for products that require a high-barrier package to protect against oxygen or moisture. A lap seal's integrity depends on the outer film layer being heat-sealable.

Machine Complexity and Film Compatibility

Lap seal machines can be simpler, but they place a critical constraint on your packaging material. You must use a film where the inner layer can seal to the outer layer. Fin seal machines are more flexible and can run a wider variety of film structures without issue.

Making the Right Choice for Your Product

Your product and production goals should dictate the type of seal you choose.

- If your primary focus is minimizing material costs: A lap seal is the most efficient choice, provided your packaging film is compatible.

- If your primary focus is maximum product protection and film versatility: A fin seal offers the most reliable barrier and works with the widest range of materials.

- If you are producing standard honey sticks: A 3-side seal machine, which will utilize either a fin or lap seal for the vertical seam, is the industry-standard equipment for this application.

Ultimately, understanding these sealing fundamentals empowers you to make a more informed packaging decision that benefits both your product and your bottom line.

Summary Table:

| Seal Type | Key Characteristic | Best For |

|---|---|---|

| Fin Seal | Seals inner-to-inner; creates a 'fin' | Maximum product protection & film versatility |

| Lap Seal | Overlaps film edges; flat seam | Minimizing material costs |

| 3-Side Seal | Standard for stick packs (top, bottom, back) | Producing standard honey sticks |

| 4-Side Seal | Seals two film pieces on all four sides | Flat sachets (less common for sticks) |

Ready to optimize your honey stick packaging line?

As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the honey stick machines and expert guidance to help you select the perfect sealing technology for your needs. Whether your priority is reducing material costs with a lap seal or ensuring superior product protection with a fin seal, we have the equipment and knowledge to maximize your production efficiency and protect your brand.

Contact our packaging experts today to discuss your specific requirements and get a quote.

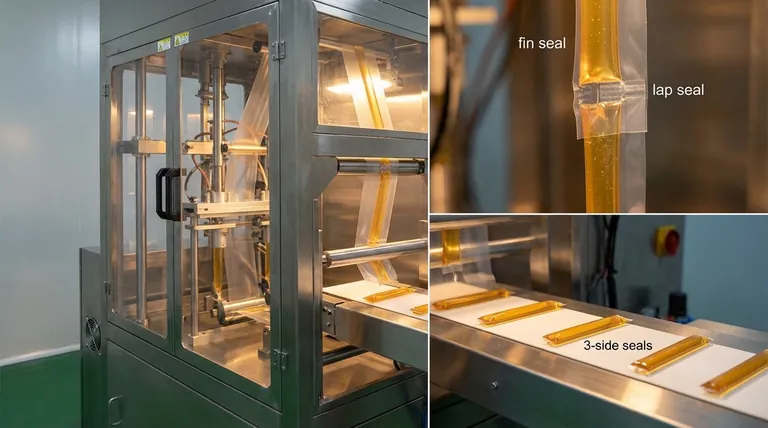

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Stainless Steel Jack Type Honey Comb Press Machine Wax and Honey Separator

- Electric Double Wall Honey Filtering Machine Purifier Equipment for Honey Processing Plant

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- How do modern honey extraction and automated filling equipment contribute to honey export competitiveness?

- What primary technical challenges are addressed by automated honey-filling machinery? Boost Your Commercial API Precision

- Why is high-precision filling and packaging equipment critical for honey? Elevate Your Brand to High-End Markets

- Why is specialized Honey Extraction and Filling Machinery critical? Unlock Scalability for Your Apiary

- What is the role of industrial-grade honey filling machines in standardized production? Expert Guide to PDO/PGI Quality

- What are the types of bottling machines used for honey? Find the Right Filler for Your Scale

- What are the options for packing honey in a processing plant? Match Your Machine to Your Production Scale

- How does automated honey sampling and filling equipment assist in safety evaluations? Ensure Lab-Grade Data Integrity