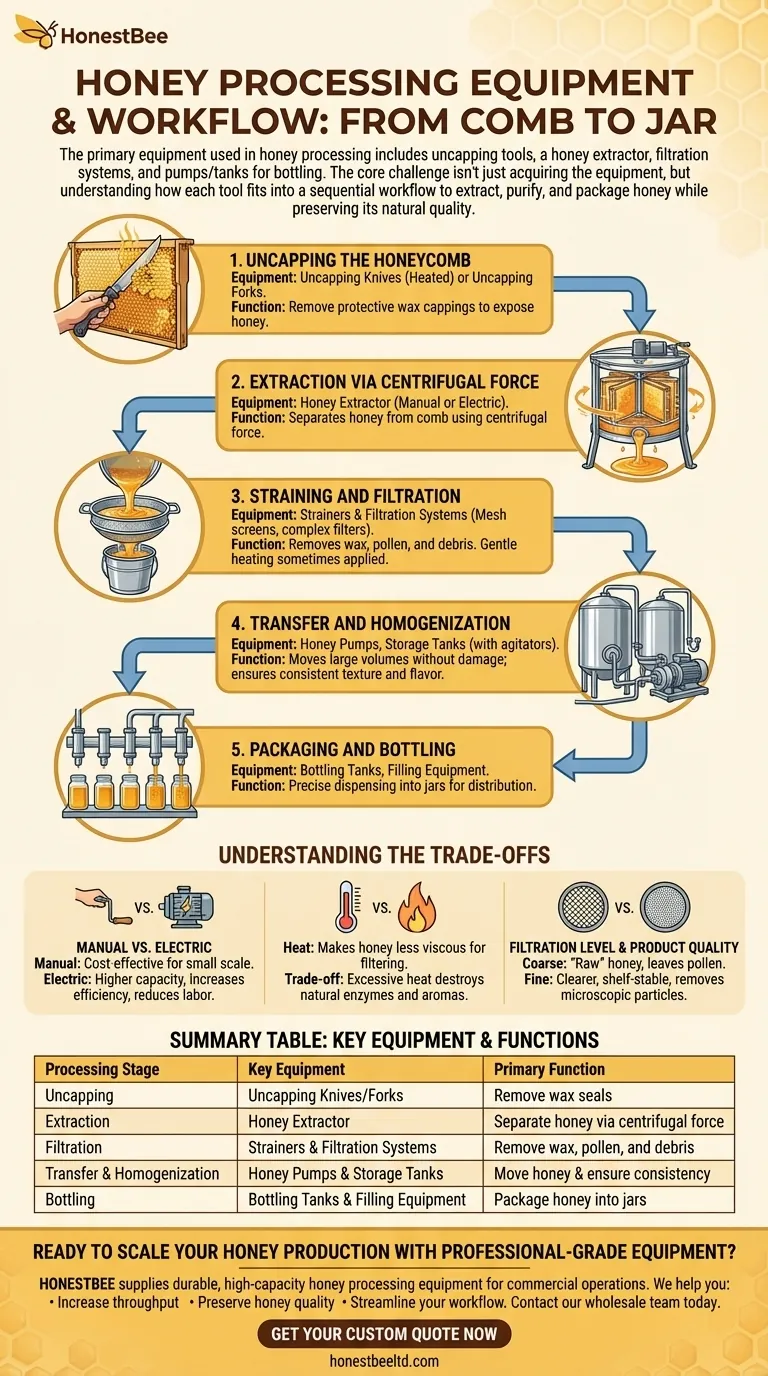

The primary equipment used in honey processing includes uncapping tools to open the honeycomb, a honey extractor to separate the honey using centrifugal force, a filtration or straining system to remove wax and debris, and pumps and tanks for transferring and bottling the final product. Each piece of equipment corresponds to a specific stage in the journey from raw honeycomb to a jar of pure honey.

The core challenge in honey processing isn't just acquiring the equipment, but understanding how each tool fits into a sequential workflow designed to extract, purify, and package honey while preserving its natural quality.

The Honey Processing Workflow: From Comb to Jar

The transformation of honey from its raw state in the comb to a marketable product follows a clear, multi-step process. Each stage requires specific equipment to ensure efficiency and maintain the honey's integrity.

Step 1: Uncapping the Honeycomb

Before honey can be extracted, the protective wax cappings that bees place over each cell must be removed.

Specialized tools like uncapping knives (which can be heated) or uncapping forks are used to slice or lift these wax caps off the frame, exposing the honey within.

Step 2: Extraction via Centrifugal Force

This is the heart of the process, where honey is separated from the wax comb.

Frames of uncapped honeycomb are placed inside a honey extractor. This device spins the frames at high speed, using centrifugal force to sling the honey out of the cells and onto the inner wall of the extractor drum, where it collects at the bottom.

Step 3: Straining and Filtration

Raw extracted honey contains particles of beeswax, pollen, and other hive debris that must be removed.

The collected honey is passed through a strainer or filtration system. This can range from a simple mesh screen for coarse filtering to more complex systems. Gentle heating is sometimes applied to reduce the honey's viscosity, allowing it to pass through filters more easily.

Step 4: Transfer and Homogenization

For commercial operations, moving large volumes of sticky honey efficiently is a significant challenge.

Honey pumps, such as sanitary positive displacement pumps, are used to transfer the filtered honey to storage or bottling tanks without introducing air or damaging its delicate structure. Large tanks may also use agitators for homogenization, ensuring a consistent texture and flavor across an entire batch.

Step 5: Packaging and Bottling

The final step is to package the purified honey for consumers.

This involves a bottling tank, which holds the finished honey, and filling equipment that dispenses a precise amount into jars or containers, preparing it for distribution.

Understanding the Trade-offs

Selecting the right equipment involves more than just knowing the steps; it requires understanding the key trade-offs that impact both the final product and the efficiency of your operation.

Manual vs. Electric Equipment

For hobbyists or small-scale producers, manual extractors and simple uncapping forks are cost-effective and sufficient.

For medium to large-scale operations, electric extractors are essential. Their higher capacity and automated operation drastically increase efficiency and reduce manual labor.

The Critical Role of Heat

Applying gentle heat makes honey less viscous, which is crucial for efficient filtering and pumping.

However, this presents a significant trade-off. Excessive heat can destroy the natural enzymes and delicate aromas that define high-quality honey. The goal is to use the lowest possible temperature that achieves the necessary fluidity.

Filtration Level and Product Quality

Coarse straining removes visible impurities like wax while leaving beneficial components like pollen. This is often characteristic of honey labeled as "raw."

Finer filtration produces a clearer, more shelf-stable product but can remove pollen and other microscopic particles, which some consumers value. The choice of filtration directly impacts the final product's characteristics and market position.

Making the Right Choice for Your Scale

Your operational goals—from a small hobby to a commercial enterprise—should dictate your equipment choices.

- If your primary focus is hobbyist beekeeping: A manual uncapping fork, a small two-frame manual extractor, and a simple bucket-top strainer are all you need.

- If your primary focus is small-scale commercial production: Invest in an electric extractor, a dedicated uncapping tank, and a quality honey pump to streamline your workflow and improve efficiency.

- If your primary focus is a large-scale packing operation: An automated line with industrial uncappers, large-capacity radial extractors, controlled heating and filtration systems, and a complete bottling line is required.

Choosing the right equipment is about matching the technology to your specific processing goals, ensuring both quality and efficiency.

Summary Table:

| Processing Stage | Key Equipment | Primary Function |

|---|---|---|

| Uncapping | Uncapping Knives/Forks | Remove wax seals from honeycomb cells |

| Extraction | Honey Extractor (Manual/Electric) | Separate honey from comb using centrifugal force |

| Filtration | Strainers & Filtration Systems | Remove wax, pollen, and debris from honey |

| Transfer & Homogenization | Honey Pumps & Storage Tanks | Move honey efficiently and ensure batch consistency |

| Bottling | Bottling Tanks & Filling Equipment | Package honey into jars for distribution |

Ready to Scale Your Honey Production with Professional-Grade Equipment?

As a commercial apiary or beekeeping equipment distributor, you understand that efficiency and product quality are paramount. HONESTBEE supplies the durable, high-capacity honey processing equipment—from industrial extractors to sanitary pumps and bottling lines—that commercial operations rely on.

We help you:

- Increase throughput with equipment designed for heavy-duty use.

- Preserve honey quality with temperature-controlled systems that protect delicate flavors.

- Streamline your workflow with integrated solutions that reduce labor and waste.

Contact our wholesale team today to discuss your specific needs and get a quote on the professional equipment that will power your growth.

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Honey Press Wax Press with Tank

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- What are the unique characteristics of honey presses? Maximize Honey Yield for Small-Scale Beekeeping

- How does pressed honey compare to extracted or crush-and-strain? Unlock the Full Flavor of the Hive

- What are the main differences between centrifugal extractors and honey presses? A Guide for Commercial Apiaries

- What are the typical features and working principles of a bucket honey press? Optimize Your Honey Extraction

- What are the benefits of the screw design in a stainless steel honey pump? Preserve Honey Quality and Integrity