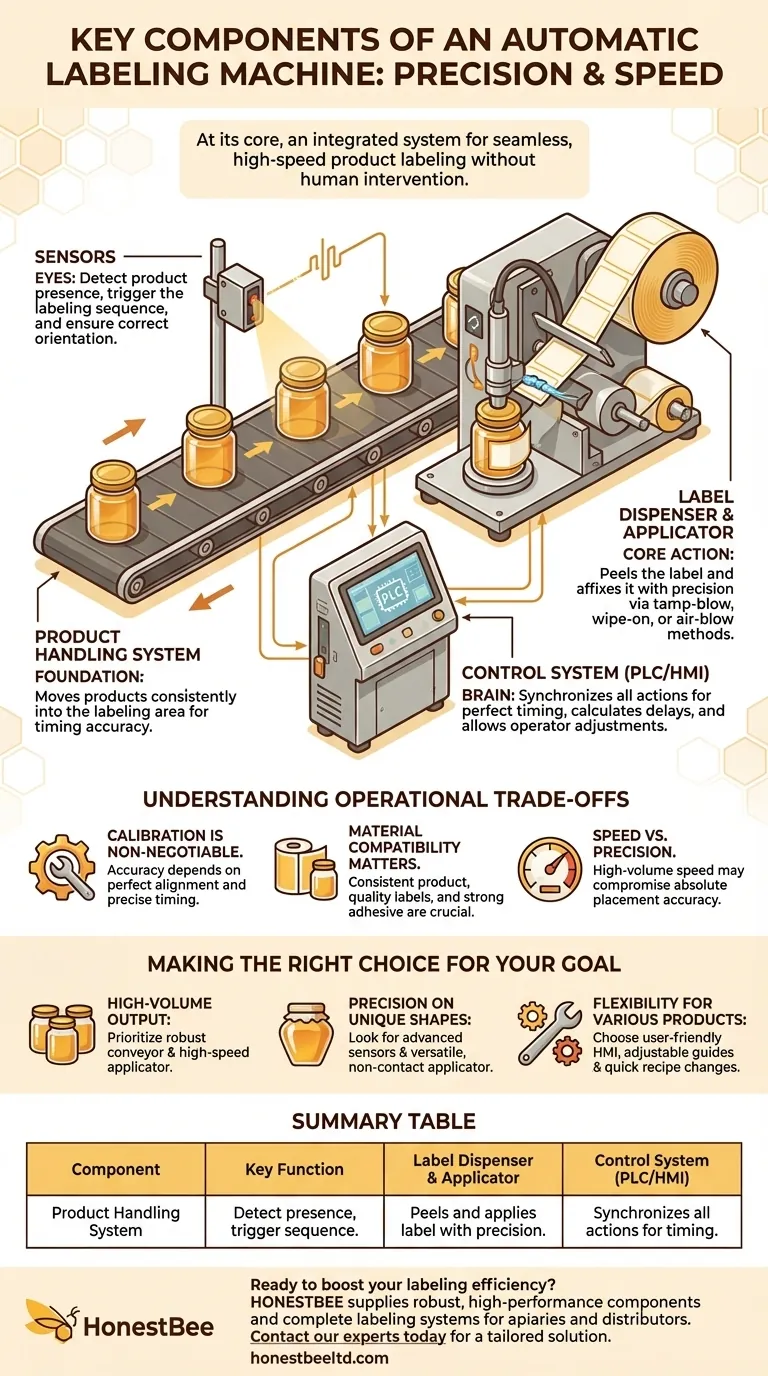

At its core, an automatic labeling machine is an integrated system designed for precision and speed. Its key components are a product handling system (like a conveyor), sensors to detect the product, a label dispensing and application head to place the label, and a central control system to synchronize every action. These parts work in a seamless, high-speed sequence to take a product, sense its position, and affix a label exactly where it needs to go without human intervention.

An automatic labeling machine isn't just a collection of parts; it's a precisely orchestrated system where each component performs a specific task in a high-speed chain of events, transforming a manual process into a highly efficient, automated workflow.

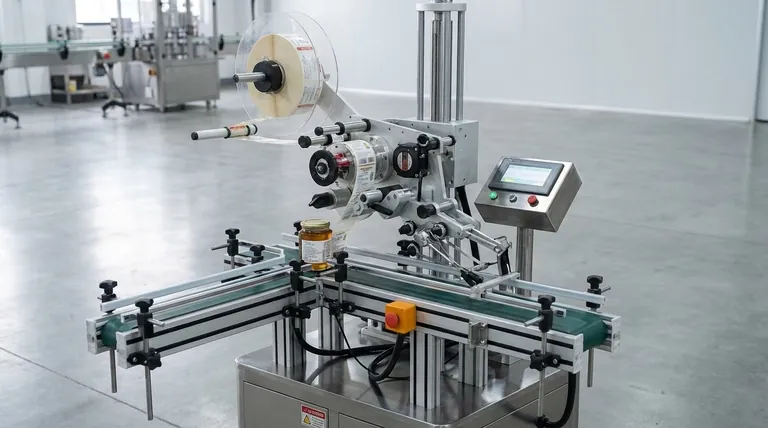

The System in Motion: A Component-by-Component Breakdown

To truly understand an automatic labeling machine, it's best to follow the path a product takes as it moves through the system. Each component plays a critical, time-sensitive role.

The Foundation: Product Handling and Transport

The journey begins with the conveyor belt or another product handling mechanism. Its job is to move products into the labeling area at a consistent speed and spacing.

This consistency is fundamental. Any variation in speed or position can throw off the timing for the rest of the system, leading to misplaced labels.

The Eyes: Sensors for Detection and Timing

As the product travels on the conveyor, it passes one or more sensors. These are the eyes of the machine.

A primary sensor, often a photoelectric sensor, detects the leading edge of the product. This detection acts as a trigger, signaling the control system that a product has arrived and is ready for a label.

More advanced systems may use sensors to verify the product's shape, orientation, or size, ensuring the correct label is applied to the correct item.

The Core Action: The Label Dispenser and Applicator

Once the sensor triggers the action, the label head activates. This unit is responsible for the two most critical steps in the process.

First, the dispenser pulls the label's backing paper around a sharp plate, causing the adhesive label to peel away and present itself.

Second, the applicator affixes the separated label to the product. Common methods include a tamp-blow (a pad extends and blows the label on), a wipe-on (the product brushes past a roller that applies the label), or an air-blow (a jet of air blows the label onto the product without contact).

The Brain: The Control System

The control system, typically a Programmable Logic Controller (PLC), is the brain that synchronizes everything.

It receives the signal from the product sensor, calculates the timing based on conveyor speed, and sends precise commands to the label head to dispense and apply the label at the exact right moment. Modern machines use a Human-Machine Interface (HMI) screen to allow operators to adjust these settings easily.

Understanding the Operational Trade-offs

While highly efficient, the performance of an automatic labeling machine depends on a delicate balance of factors. Understanding these trade-offs is key to successful operation.

Calibration is Non-Negotiable

The machine's accuracy is entirely dependent on its setup and calibration. The sensors must be perfectly aligned, and the timing delay between product detection and label application must be precisely configured. Even a small misalignment can result in skewed or misplaced labels, especially at high speeds.

Material Compatibility Matters

The system is only as reliable as the materials it runs. Inconsistent product dimensions, low-quality label stock, or weak adhesive can cause frequent jams, misfeeds, and application failures. The machine, products, and labels must all be compatible to work as an effective system.

Speed vs. Precision

The references highlight the ability to label thousands of packages per hour. However, there is often a trade-off between maximum operational speed and placement accuracy. Pushing a machine to its absolute speed limit can sometimes introduce slight inconsistencies in label placement that may not be acceptable for premium products.

Making the Right Choice for Your Goal

Understanding these components allows you to select or optimize a machine based on your specific production needs.

- If your primary focus is high-volume output: Prioritize a machine with a robust conveyor system and a high-speed applicator head designed for simple, repeatable tasks.

- If your primary focus is precision on unique shapes: Look for advanced sensor packages and a versatile, non-contact applicator like an air-blow system.

- If your primary focus is flexibility for various products: Choose a machine with a user-friendly HMI for quick recipe changes and easily adjustable guide rails and sensor positions.

Ultimately, knowing how these components function together empowers you to move beyond the specifications on a sheet and evaluate how a machine will perform in your real-world operational environment.

Summary Table:

| Component | Key Function |

|---|---|

| Product Handling System | Moves products consistently into the labeling area. |

| Sensors | Detect product presence and trigger the labeling sequence. |

| Label Dispenser & Applicator | Peels and applies the label with precision. |

| Control System (PLC/HMI) | The brain that synchronizes all actions for perfect timing. |

Ready to boost your labeling efficiency?

HONESTBEE supplies the robust, high-performance components and complete labeling systems that commercial apiaries and distributors rely on. Whether you need a reliable conveyor, precise sensors, or a durable label applicator head for high-volume honey jar labeling, we provide the wholesale-focused solutions to keep your operation running smoothly.

Contact our experts today to discuss your specific needs and get a tailored solution that delivers precision and speed.

Visual Guide

Related Products

- Automatic In-Line Flat Surface Labeling Machine

- HONESTBEE Pneumatic Flat Surface Labeling Machine

- Semi Automatic Round Bottle Labeling Machine

- Professional Durable Customizable Blister Packing Machine

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

People Also Ask

- What is the importance of high-quality printing and documentation in honey production? Elevate Your Brand & Value

- What is the technical significance of terminal product labeling systems? Build Trust in Sustainable Beekeeping

- How does container shape influence the efficiency of the honey labeling process? Choose the Best Jar for Automation

- In what ways do advanced honey packaging and labeling equipment enhance the market reputation of honey products?

- What are the advantages and disadvantages of manually applying honey labels? Expert Comparison for Your Brand

- What is the importance of modern labeling and coding machines in honey distribution? Secure Compliance & Market Trust

- How does diverse labeling equipment for honey products enhance marketability? Boost Traceability & Premium Branding

- What is the function of batch coding and traceability systems in honey supply chain management? Build Trust & Safety