The most critical features of a honey warming source are its ability to provide slow, even heat and maintain a precise temperature. An ideal system keeps the honey between ambient temperature and a maximum of 100°F (37.8°C), ensuring it can liquefy over 12 to 24 hours without creating damaging hot spots.

The fundamental goal is not simply to melt crystallized honey, but to gently return it to a liquid state while preserving the delicate enzymes, aromas, and flavors that define its quality. True success is measured by what you don't do: overheat or damage the product.

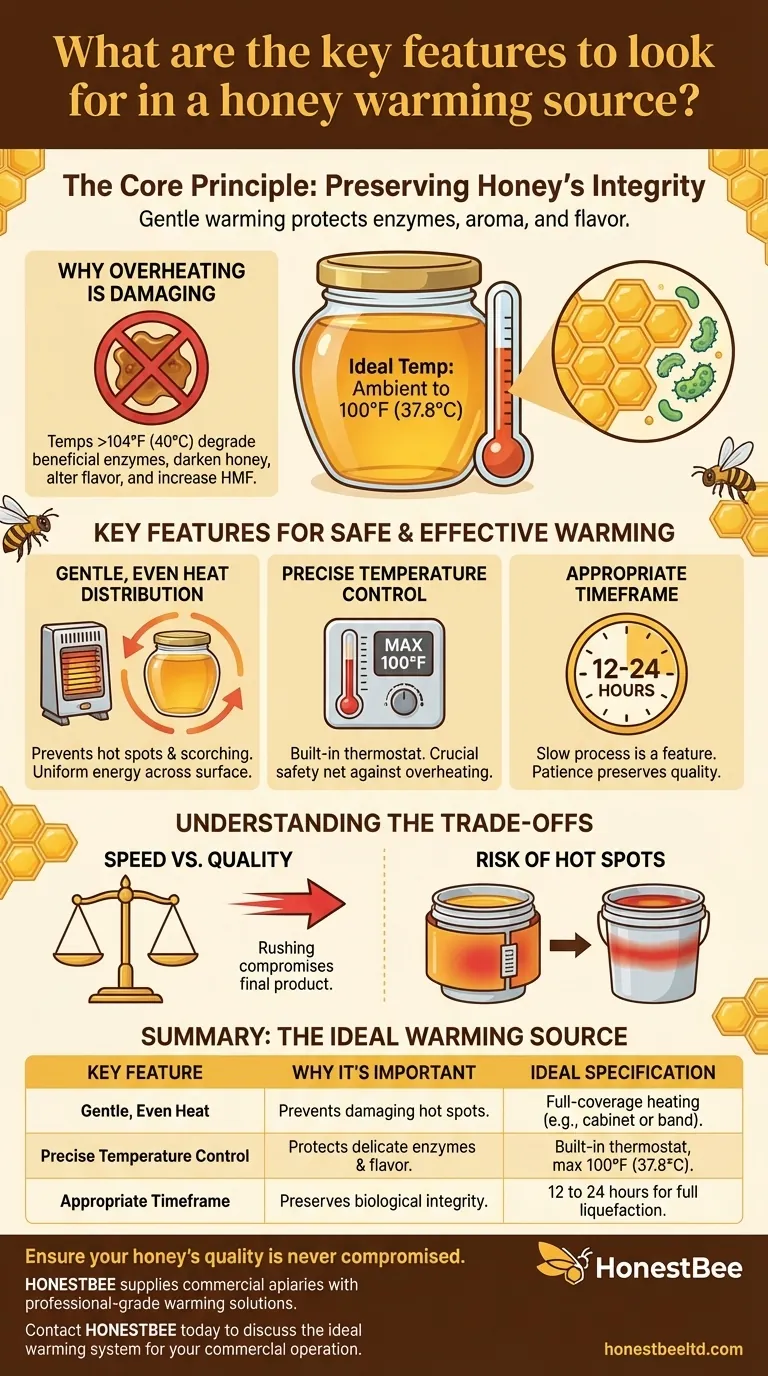

The Core Principle: Preserving Honey's Integrity

Honey is a sensitive biological product. Its unique characteristics are easily damaged by improper handling, especially the application of excessive or rapid heat. Understanding why this happens is key to choosing the right warming method.

Why Overheating is Damaging

Applying heat above approximately 104°F (40°C) begins to degrade the beneficial enzymes, like diastase and invertase, that are naturally present in raw honey. Higher temperatures also darken the honey, alter its flavor profile, and increase levels of a compound called HMF (hydroxymethylfurfural), which is an indicator of heat damage and aging.

The Ideal Temperature Window

The target temperature range of ambient to 100°F (37.8°C) is not arbitrary. It closely mimics the natural, stable temperature maintained by bees inside a hive. Staying within this window ensures you are warming the honey, not cooking it.

Key Features for Safe and Effective Warming

To achieve this gentle warming, a heating source must have specific characteristics. Each feature directly addresses the goal of preserving quality.

Gentle, Even Heat Distribution

The heat source must distribute its energy uniformly across the entire surface of the container. This is the single most important factor in preventing "hot spots." A hot spot can scorch the honey it touches, ruining that portion and degrading the entire batch even if the average temperature remains low.

Precise Temperature Control

Reliable temperature regulation is non-negotiable. A quality warming source will have a built-in thermostat or controller that prevents the temperature from exceeding the 100°F (37.8°C) threshold. This provides a crucial safety net against accidental overheating.

Appropriate Timeframe

The target liquefaction time of 12 to 24 hours should be seen as a feature, not a drawback. This slow, patient process is a direct result of applying low, gentle heat. Any method promising to liquefy a large bucket of honey in an hour or two is almost certainly using excessive temperatures that will damage the product.

Understanding the Trade-offs

Choosing a warming method involves balancing efficiency with quality. Rushing the process will always compromise the final product.

Speed vs. Quality

The most common mistake is prioritizing speed. Methods like placing a honey bucket in hot water or using a standard heating pad are fast but extremely difficult to control. They create intense hot spots where the container meets the heat source, leading to inevitable damage.

The Risk of "Hot Spots"

A simple heated band or blanket without full-coverage circulation can create a ring of overheated honey while the core remains solid. This unevenness is highly detrimental. A system that warms the surrounding air, like a cabinet, is often superior because it provides the most even heat possible.

Making the Right Choice for Your Goal

Your ideal solution depends on the scale of your operation, but the underlying principles remain the same.

- If your primary focus is small batches or hobbyist use: A simple insulated box with a very low-wattage heat source (like a specific reptile heater or a 25-watt light bulb) connected to a reliable thermostat can be a cost-effective solution.

- If your primary focus is commercial quality and consistency: Invest in a purpose-built honey warming cabinet or full-coverage band heaters designed specifically to provide low, uniform, and thermostatically-controlled heat.

By prioritizing gentle, controlled heat, you ensure your honey remains as perfect as the bees made it.

Summary Table:

| Key Feature | Why It's Important | Ideal Specification |

|---|---|---|

| Gentle, Even Heat | Prevents damaging hot spots that scorch honey. | Full-coverage heating (e.g., cabinet or band). |

| Precise Temperature Control | Protects delicate enzymes and flavor by avoiding overheating. | Built-in thermostat, max 100°F (37.8°C). |

| Appropriate Timeframe | Slow warming preserves the honey's biological integrity. | 12 to 24 hours for full liquefaction. |

Ensure your honey's quality is never compromised by improper warming.

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with wholesale-focused, professional-grade warming solutions. Our equipment is engineered to deliver the precise, gentle heat required to liquefy honey while perfectly preserving its enzymes, aroma, and flavor.

Contact HONESTBEE today to discuss the ideal warming system for your commercial operation.

Visual Guide

Related Products

- HONESTBEE Commercial Upright Honey Melter

- Heavy Duty Stainless Steel Honey Processing Machine Decrystallizing Tank

- Honey Tank Heater Drum Heating Blanket for Honey Barrel

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

People Also Ask

- How do industrial-grade temperature control systems inhibit HMF in honey? Protect Your Quality and Legal Compliance

- What is the Bee Blanket, and how does it help in heating honey? Gentle Warming for Perfect Honey Quality

- Why is high-precision temperature control equipment essential for honey processing? Protect Bioactivity and Quality

- What types of drums is the honey warming blanket heater compatible with? Versatile Heating for Steel and Poly Drums

- How does the use of controlled heating equipment impact honey's H2O2 production? Protect Your Honey's Bioactivity

- How many times can you decrystallize honey? The truth about quality loss with each cycle.

- What temperature does the Bee Blanket maintain honey at? Preserve Quality with Precise 110°F Heating

- What is the primary function of Peltier Modules in beehives? Boost Winter Colony Survival with Solid-State Heating