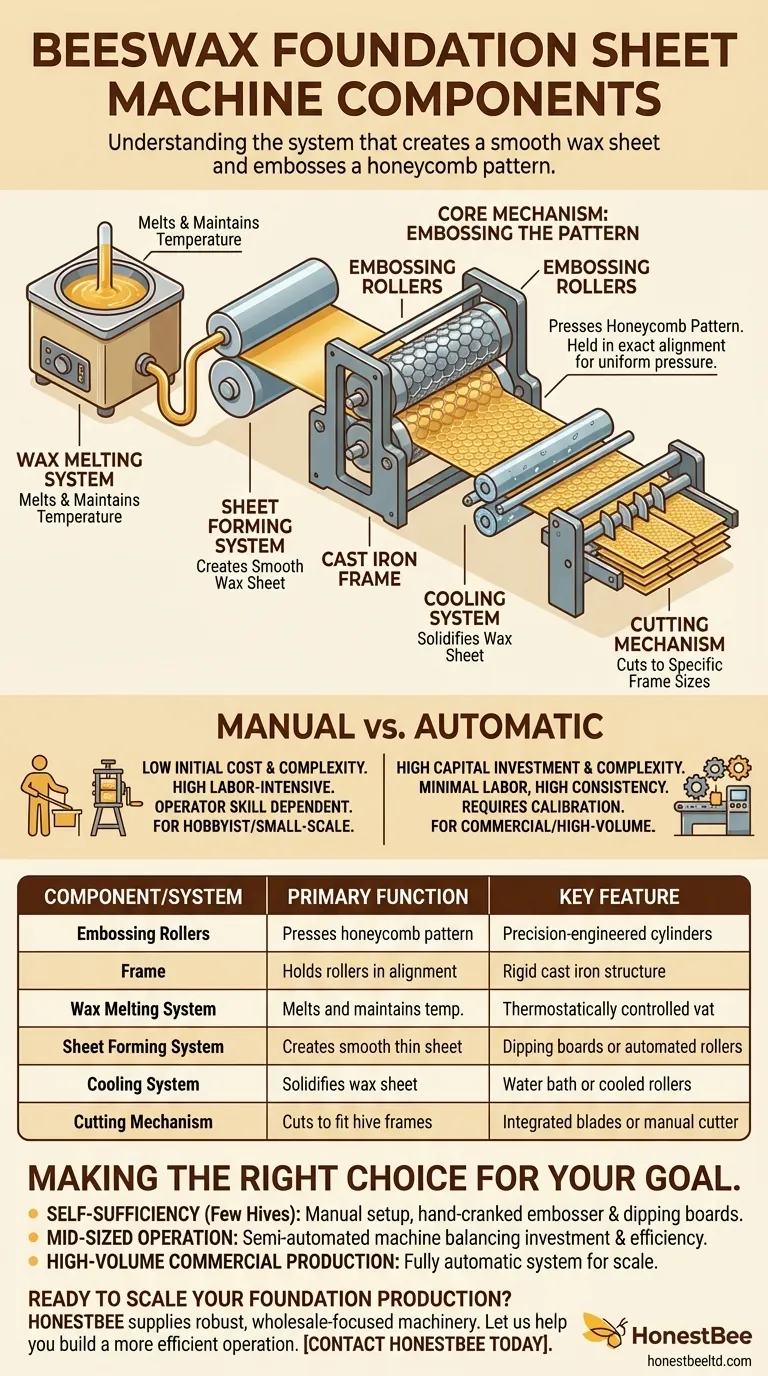

At its core, a beeswax foundation machine is built around two engraved rollers that emboss a honeycomb pattern onto a sheet of wax. While these rollers are the central component, a complete system also incorporates mechanisms for melting wax, forming it into a uniform sheet, and cutting it to the final size.

The critical insight is that a "foundation machine" isn't a single device but a system that accomplishes two tasks: creating a smooth wax sheet and embossing it. The components involved simply reflect how automated you want that two-step process to be.

The Core Mechanism: Embossing the Pattern

The heart of any foundation machine is the part that creates the hexagonal cell imprints. This function relies on just two key components working in perfect harmony.

Embossing Rollers

The embossing rollers are two precision-engineered cylinders, typically fixed horizontally within a frame. The surface of each roller is engraved with the negative of a honeycomb cell pattern. As a smooth sheet of beeswax passes between them, the rollers press this pattern into both sides of the wax.

The Frame

The cast iron frame provides the rigid structure necessary to hold the embossing rollers in exact alignment. It maintains the precise, consistent pressure required to create a perfect and uniform cell pattern across the entire foundation sheet.

The Supporting Systems: From Raw Wax to Finished Sheet

Beyond the core embossing unit, more complete and automated systems include additional components to manage the entire workflow from raw beeswax to a ready-to-use foundation sheet.

Wax Melting System

Before it can be formed, raw beeswax must be melted and held at a consistent temperature. This is often accomplished with a thermostatically controlled melting vat or a water-jacketed melter (bain-marie) to prevent scorching the wax.

Sheet Forming System

This system creates the smooth, thin sheet of wax that will be fed into the embossing rollers. This can be a simple set of dipping boards used to manually create sheets in a vat of molten wax, or an automated mechanism where liquid wax flows onto rollers or a belt to form a continuous ribbon.

Cooling System

To ensure the wax sheet is solid enough for embossing and cutting, a cooling system is necessary. In simple setups, this may just be a water bath for the dipping boards. In automated machines, it often involves cooled rollers or a flow of air or water.

Cutting Mechanism

The final step is to cut the embossed foundation to fit specific hive frame sizes. This can range from a simple knife or pizza cutter used with a cutting board in manual operations to integrated cutting blades that automatically slice the sheets to preset dimensions in a fully automatic machine.

Understanding the Trade-offs: Manual vs. Automatic

Choosing the right equipment depends entirely on your operational scale and goals. The primary trade-off is between the low initial cost of manual systems and the high efficiency of automated ones.

Cost and Complexity

A manual setup involving dipping vats and a hand-cranked embosser has a very low barrier to entry. A fully automatic machine is a significant capital investment, incorporating complex electronics and mechanics for precise control over the entire process.

Labor and Consistency

Manual methods are highly labor-intensive and the quality of the final sheet depends heavily on operator skill. Automatic machines produce thousands of highly uniform sheets with minimal labor, but require careful calibration and maintenance.

Operational Scale

For a hobbyist or small-scale beekeeper, a manual system is often sufficient. For a commercial apiary or a beekeeping supplier, the speed and consistency of an automatic machine are essential for efficient production.

Making the Right Choice for Your Goal

Selecting the right components means matching the equipment to the needs of your apiary.

- If your primary focus is self-sufficiency for a few hives: A manual setup with a hand-cranked embosser and dipping boards is the most practical and cost-effective approach.

- If your primary focus is supplying a mid-sized operation: A semi-automated machine that combines the sheet-forming and embossing steps offers a strong balance between investment and efficiency.

- If your primary focus is high-volume commercial production: A fully automatic system that manages the process from melting wax to stacking finished sheets is the necessary tool for achieving scale.

By understanding these core components and systems, you can choose the right tools to create the perfect foundation for a thriving hive.

Summary Table:

| Component/System | Primary Function | Key Feature |

|---|---|---|

| Embossing Rollers | Presses honeycomb pattern into wax sheet. | Precision-engineered cylinders. |

| Frame | Holds rollers in alignment for uniform pressure. | Rigid cast iron structure. |

| Wax Melting System | Melts and maintains wax at consistent temperature. | Thermostatically controlled vat. |

| Sheet Forming System | Creates a smooth, thin sheet of wax for embossing. | Dipping boards or automated rollers. |

| Cooling System | Solidifies wax sheet for handling and embossing. | Water bath or cooled rollers. |

| Cutting Mechanism | Cuts embossed sheet to fit specific hive frames. | Integrated blades or manual cutter. |

Ready to Scale Your Foundation Production?

Understanding the components is the first step; acquiring the right equipment is the next. Whether you are a commercial apiary or a beekeeping equipment distributor, HONESTBEE supplies the robust, wholesale-focused machinery and supplies you need for high-volume, consistent foundation sheet production.

Let us help you build a more efficient and profitable operation. Contact HONESTBEE today to discuss your specific needs and explore our range of solutions.

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

People Also Ask

- Why is precise dry matter analysis essential for beeswax production? Unlock the Secrets of Feed Efficiency

- What is the primary industrial application of smooth rollers in beeswax sheet production? Achieving Uniform Foundations

- What is a comb foundation mill? A Strategic Tool for Stronger, More Productive Hives

- What is the recommended method for stacking embossed wax sheets after milling? Prevent Sticking & Ensure Quality

- What is the purpose of a manual wax roller? Create Pure, Self-Sufficient Foundation for Your Hive

- What is the importance of soaping the rollers during milling? Prevent Wax Adhesion & Equipment Downtime

- How does the beeswax flatting and embossing machine prepare the wax for processing? Achieve Perfectly Uniform Wax Sheets

- How does the cooling cylinder achieve beeswax solidification? Master Thermal Exchange for High-Quality Foundations