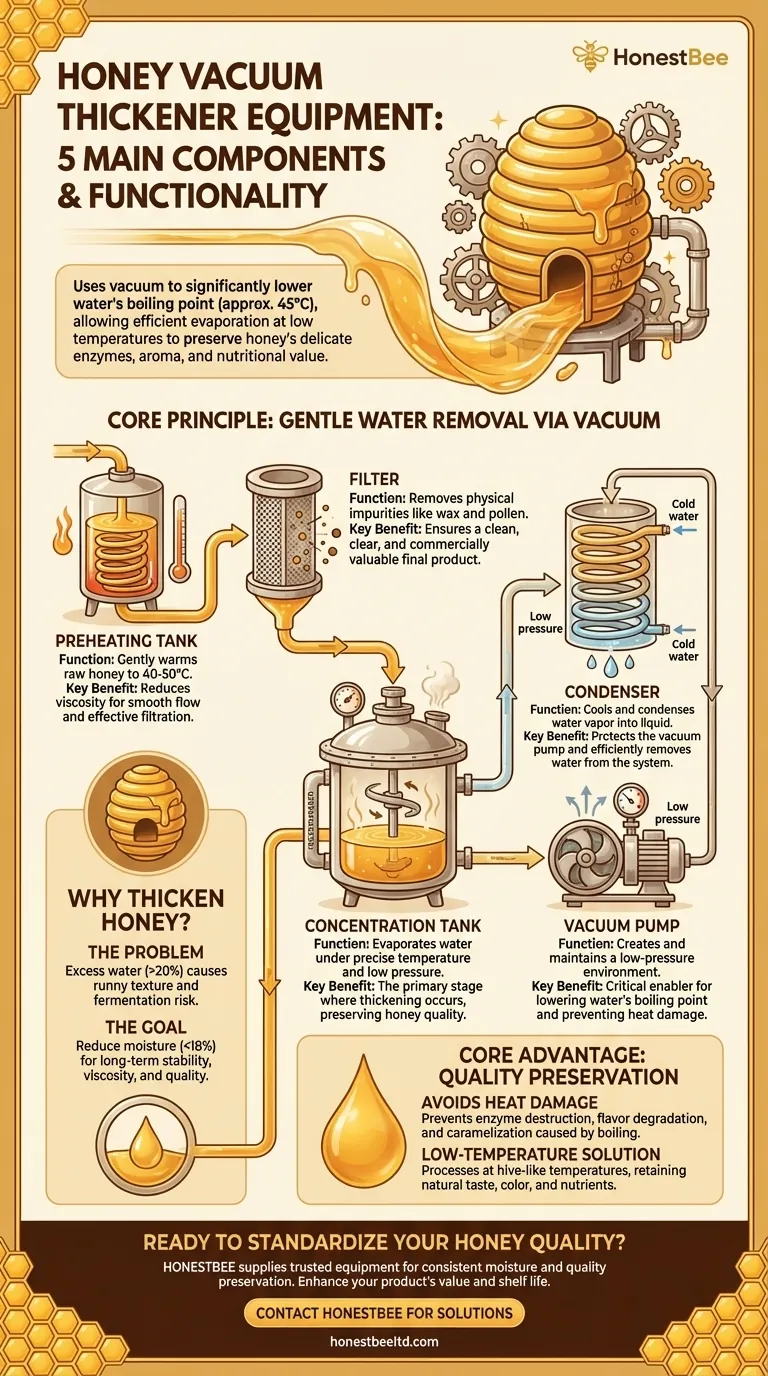

At its core, a honey vacuum thickener is a specialized system designed for a single purpose: gently removing excess water from raw honey. The equipment is composed of five main components: a preheating tank, a filter, a concentration tank, a condenser, and a vacuum pump. Each part plays a critical role in the process of thickening the honey without damaging its natural qualities.

The central principle of this technology is not to boil the honey, but to use a vacuum to significantly lower the boiling point of water. This allows for efficient water removal at low temperatures, preserving the honey's delicate enzymes, aroma, and nutritional value.

Why Honey Needs Thickening

The Problem of Excess Water

Raw honey, especially from nectar with high moisture content or harvested in humid conditions, can have a water content exceeding 20%. This excess moisture makes the honey runny and, more importantly, susceptible to fermentation by naturally occurring yeasts.

The Goal: Stability and Quality

To be stable for long-term storage, honey's water content must be reduced to below 18%. The vacuum thickening process achieves this, increasing the honey's viscosity (thickness) and ensuring it meets quality standards without spoiling.

A Component-by-Component Functional Breakdown

The Preheating Tank: Preparing the Honey

The process begins here. Raw honey is gently warmed in the preheating tank, typically to around 40-50°C.

This warming does not remove water. Its sole purpose is to reduce the honey's viscosity, making it flow more easily through the system for effective filtering and processing.

The Filter: Ensuring Purity

After preheating, the less viscous honey passes through a filter. This stage is designed to remove physical impurities such as wax particles, pollen debris, and other hive matter.

This step ensures the final product is clean and clear, improving its commercial value and appearance.

The Concentration Tank: The Heart of the Operation

This is a sealed, jacketed vessel where the primary thickening takes place. The filtered honey is fed into this tank, which is connected to the vacuum pump.

The tank's jacket allows for precise temperature control, keeping the honey warm while the vacuum is applied. The combination of gentle heat and low pressure causes the water in the honey to evaporate rapidly.

The Condenser: Capturing the Water Vapor

The water vapor evaporated from the honey in the concentration tank is drawn out by the vacuum. It then enters the condenser.

The condenser cools this vapor, turning it back into liquid water. This prevents the vapor from entering and potentially damaging the vacuum pump and allows for the efficient removal of water from the system.

The Vacuum Pump: The Critical Enabler

The vacuum pump is the engine that drives the entire process. It is responsible for creating and maintaining the low-pressure environment inside the concentration tank.

By lowering the atmospheric pressure, the pump dramatically reduces the boiling point of water from 100°C (212°F) to as low as 45°C (113°F). This is the key to preserving the honey's quality.

Understanding the Core Advantage: Quality Preservation

Avoiding Heat Damage

Simply heating honey to 100°C to boil off water would be disastrous. This high heat would destroy beneficial enzymes like diastase and invertase, degrade delicate flavors, and darken the honey's color through caramelization.

The Low-Temperature Solution

The vacuum system is a sophisticated solution that bypasses this problem entirely. By removing water at temperatures similar to those found inside a warm beehive, it protects the honey’s natural composition.

The result is a product that is thick and stable but retains the taste, color, and nutritional profile of its raw state. This is why the equipment is noted for its high efficiency and good effectiveness.

Is This Equipment Right for Your Operation?

Understanding the function of these components helps determine if this technology fits your production goals. The system is particularly well-suited for small and medium-sized honey processors seeking to standardize their product.

- If your primary focus is artisanal quality: This equipment gives you precise control to ensure your honey is stable for sale without compromising the unique floral notes and natural enzymes your customers value.

- If your primary focus is commercial consistency: The system enables you to efficiently process batches of honey to meet specific moisture and viscosity standards required for retail markets.

Ultimately, mastering this equipment allows a producer to take direct control over the final quality and shelf-stability of their honey.

Summary Table:

| Component | Primary Function | Key Benefit |

|---|---|---|

| Preheating Tank | Gently warms honey to reduce viscosity | Ensures smooth flow for processing |

| Filter | Removes wax, pollen, and other impurities | Produces a clean, clear final product |

| Concentration Tank | Evaporates water under low pressure and heat | The core chamber where thickening occurs |

| Condenser | Cools and condenses water vapor back to liquid | Protects the vacuum pump and removes water |

| Vacuum Pump | Creates a low-pressure environment | Lowers water's boiling point to preserve honey quality |

Ready to Standardize Your Honey Quality and Increase Your Production Efficiency?

HONESTBEE supplies the beekeeping supplies and equipment that commercial apiaries and distributors trust. A honey vacuum thickener is an essential piece of equipment for achieving consistent moisture levels and protecting the delicate flavor and enzymes in your honey.

Let us help you enhance your product's value and shelf life.

Contact our wholesale experts today to discuss the right equipment solutions for your operation.

Visual Guide

Related Products

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- Professional Thermostatic Conical Honey Melter

People Also Ask

- Why are specialized cold chain and deep processing technologies necessary for bee products? Ensure Maximum Bioactivity

- Why is shell freezing equipment beneficial for the honey freeze-drying process? Maximize Speed and Efficiency

- How do standardized post-harvesting processing machines ensure honey quality? Optimize Purity and Shelf Life

- How does automated processing machinery improve honey quality and purity? Enhancing Honey Standards via Automation

- What is heat treatment for honey? A Guide to Liquefying, Pasteurizing, and Preserving Quality

- Why is professional refining and purification equipment critical for commercial apiaries? Elevate Your Propolis Purity

- What are the benefits of using automated honey extraction and processing lines? Elevate Quality and Global Compliance

- How is the extracted honey collected and tested for quality? A Guide to Purity and Consistency