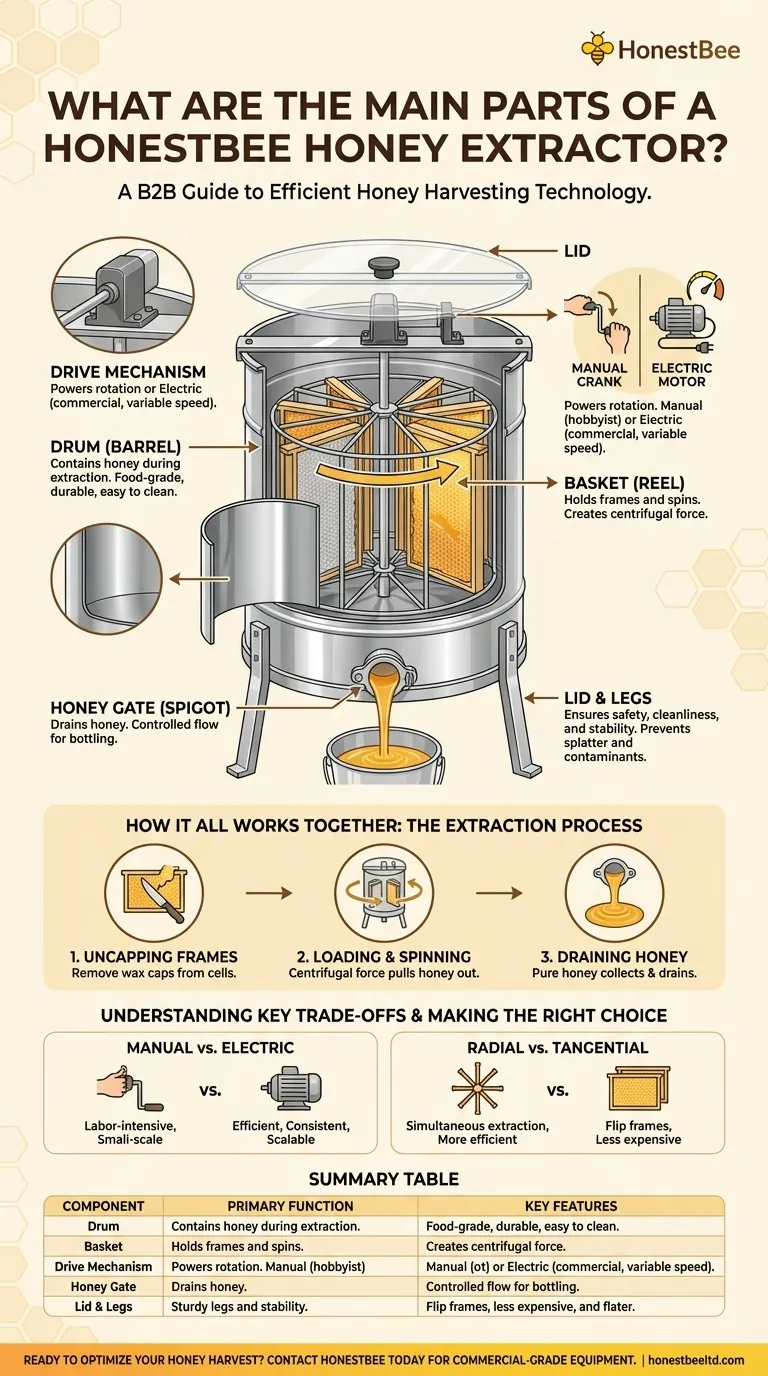

At its core, a honey extractor is a machine that uses centrifugal force to pull honey from the comb without destroying it. The main components are the drum (barrel), a rotating basket to hold the frames, a drive mechanism (either a manual crank or an electric motor), a honey gate to drain the honey, and a lid for safety and cleanliness.

A honey extractor is essentially a centrifuge designed for one purpose: to sling honey out of the comb. Understanding its key parts reveals how this simple mechanical principle allows beekeepers to harvest honey efficiently while preserving the delicate wax comb for the bees to reuse.

Deconstructing the Honey Extractor: A Component-by-Component Guide

Each part of a honey extractor serves a distinct and critical function in the extraction process. When these components work together, they create a clean and efficient system for harvesting honey.

The Drum (or Barrel)

The drum is the large, cylindrical outer body of the extractor. Its primary job is to contain the honey as it is flung from the frames.

Most modern extractors use food-grade stainless steel for the drum. This material is durable, rust-resistant, and easy to clean, which is critical for maintaining the purity of the honey.

The Basket (or Reel)

Inside the drum sits the basket, a metal framework designed to hold the uncapped honey frames securely in place. The design of this basket is what determines if an extractor is "radial" or "tangential."

This component spins rapidly, creating the centrifugal force necessary to pull the honey out of the wax cells.

The Drive Mechanism (Motor or Crank)

The drive mechanism is what powers the rotation of the basket. There are two primary types.

Manual extractors use a hand crank, which is ideal for hobbyists with only a few hives. Electric extractors use a motor, often with variable speed control, making them essential for larger-scale operations where efficiency is key.

The Honey Gate (or Spigot)

Located at the bottom of the drum, the honey gate is a simple valve or spigot. After extraction, the honey pools at the bottom of the drum.

This gate allows the beekeeper to control the flow of honey as it is drained into buckets or other storage containers.

The Lid and Legs

These are crucial supporting components. The lid covers the top of the drum during operation to prevent honey from splattering out and to keep contaminants like dust or insects from getting in.

The legs provide a stable base, raising the drum off the ground to prevent wobbling during high-speed spinning and allowing enough clearance to place a bucket under the honey gate.

How It All Works Together: The Extraction Process

The function of an extractor is best understood by looking at the process from start to finish.

Step 1: Uncapping the Frames

Before frames can be placed in the extractor, the wax caps that bees seal each honey cell with must be removed. This is typically done with a heated knife or an uncapping fork.

Step 2: Loading and Spinning

The uncapped frames are loaded vertically into the basket. The lid is secured, and the beekeeper begins to turn the crank or starts the motor.

The basket spins, generating centrifugal force that pulls the liquid honey outward and onto the inner wall of the drum.

Step 3: Draining the Honey

As the honey is extracted, it runs down the walls of the drum and collects at the bottom. Once the process is complete, the honey gate is opened to drain the pure, filtered honey for bottling. The empty combs can then be returned to the hive.

Understanding the Key Trade-offs

Choosing an extractor involves balancing cost, efficiency, and scale. Your decision will depend entirely on the size of your beekeeping operation.

Manual Crank vs. Electric Motor

A manual crank is simple, requires no electricity, and is significantly cheaper. However, it is labor-intensive and slow, making it suitable only for small-scale hobbyists.

An electric motor offers speed and consistency with minimal effort. The ability to control the speed is also crucial, as starting slowly prevents the comb from breaking apart under sudden force.

Radial vs. Tangential Design

A tangential extractor holds frames like spokes in a wheel, with one side of the comb facing out. You must extract one side, flip the frames, and then extract the other. They are less expensive but require more manual work.

A radial extractor positions the frames with the top bar facing outward. It extracts honey from both sides of the comb simultaneously, making it far more efficient for anyone with more than a few hives.

Making the Right Choice for Your Needs

Selecting the correct extractor is an investment in your beekeeping practice. Your goals will determine the best fit.

- If your primary focus is a small hobby with 1-3 hives: A small, manual, stainless steel tangential extractor is a cost-effective and perfectly adequate choice.

- If your primary focus is scaling up to 5+ hives: An electric, stainless steel radial extractor will save you an immense amount of time and labor, justifying the higher initial cost.

- If your primary focus is honey purity and equipment longevity: Always invest in a model made from food-grade stainless steel, regardless of its size or drive mechanism.

Ultimately, the right extractor empowers you to harvest your honey cleanly and efficiently, completing the rewarding cycle of beekeeping.

Summary Table:

| Component | Primary Function | Key Features |

|---|---|---|

| Drum (Barrel) | Contains the honey during extraction. | Food-grade stainless steel, durable, easy to clean. |

| Basket (Reel) | Holds frames and spins to create centrifugal force. | Radial or tangential design for different efficiencies. |

| Drive Mechanism | Powers the basket's rotation. | Manual crank (hobbyist) or electric motor (commercial). |

| Honey Gate | Drains honey from the drum after extraction. | Spigot or valve for controlled flow into containers. |

| Lid & Legs | Ensures safety, cleanliness, and stability. | Prevents splatter and contaminants; provides a stable base. |

Ready to choose the right honey extractor for your apiary?

At HONESTBEE, we supply durable, commercial-grade beekeeping equipment to commercial apiaries and distributors. Whether you're scaling your operation or need reliable wholesale supplies, our expertise ensures you get the most efficient tools for the job.

Contact our team today to discuss your needs and streamline your honey harvest!

Visual Guide

Related Products

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- Stainless Steel Beekeeping Honey Extractor Lid

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- HONESTBEE 6 Frame Three Use Electric Honey Extractor for Beekeeping

People Also Ask

- What is the consequence of extracting honey without a honey extractor? Maximize Your Apiary's Production Efficiency

- What are the benefits of using industrial centrifugal honey extractors? Boost Yield and Purity for Commercial Apiaries

- What is the function of industrial honey extractors? Boost Commercial Yields with Advanced Centrifugal Tech

- What is a stainless steel honey extractor? Boost Your Apiary's Efficiency with Professional Extraction

- What are the advantages of using efficient honey harvesting machinery? Boost Yield and Market Value for Your Apiary

- How long does it take to extract honey with an electric extractor? Automate Your Harvest for Greater Efficiency

- How do radial honey extractors work? Mastering Centrifugal Force for Efficient Commercial Extraction

- What are common problems with honey extractors and how can they be fixed? Ensure a Smooth Harvest Every Time