For a honey processing plant, your packing options scale directly with your production volume. The primary choices are compact, single-unit filling machines for smaller operations and multi-nozzle inline filling systems for larger commercial plants. Both are designed to handle the final stage after the honey has been processed.

The critical decision isn't just about the filling machine itself, but about aligning your packing capacity with the entire processing workflow—from pre-heating and filtration to final bottling.

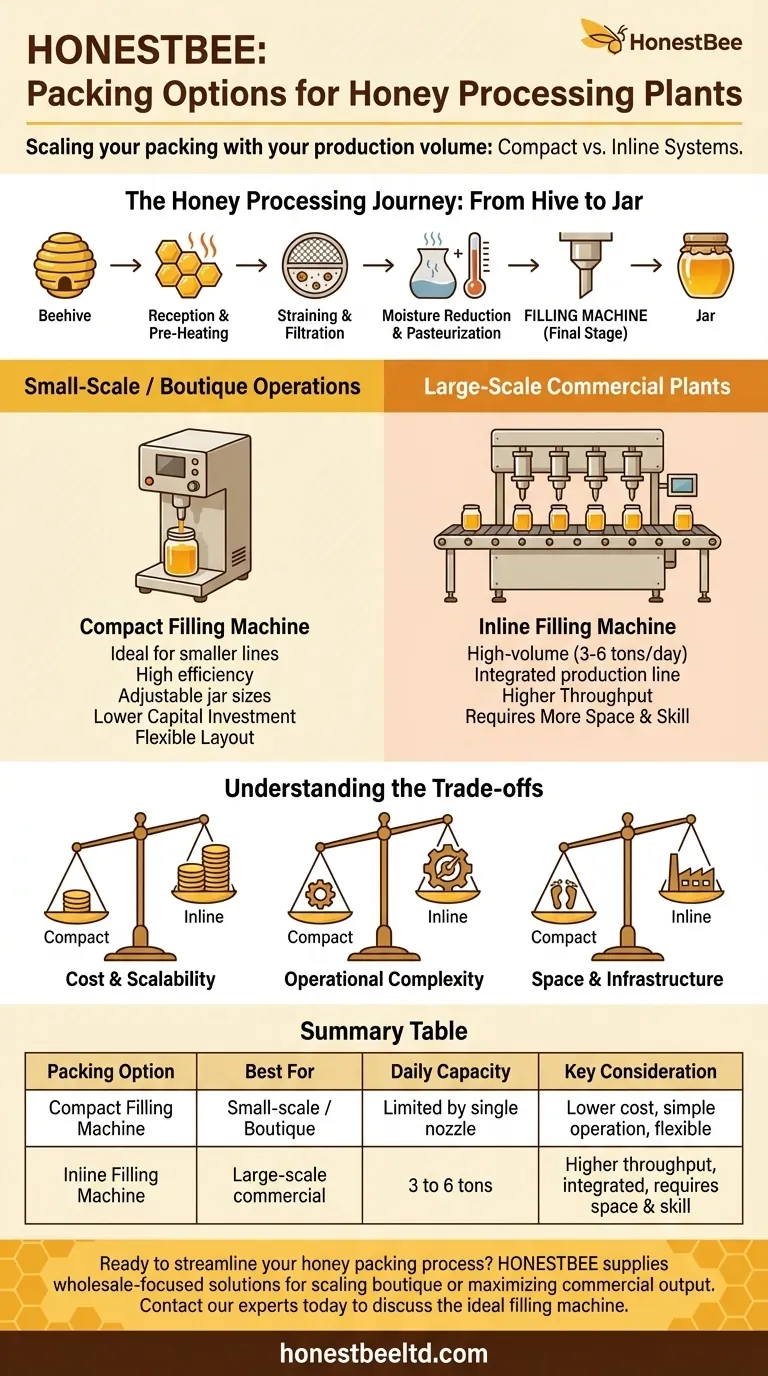

The Honey Processing Journey: From Hive to Jar

Before honey can be packed, it must undergo several crucial processing steps to ensure quality, safety, and shelf life. The filling machine is the final piece of this integrated system.

Reception and Pre-Heating

The process begins when raw honey is received at the plant. It is often gently pre-heated to lower its viscosity, making it easier to strain and filter in the subsequent steps.

Straining and Filtration

Next, the honey is agitated and passed through coarse filters or strainers. This step is essential for removing impurities like wax, bee parts, and other hive debris.

Moisture Reduction and Pasteurization

For stability, the honey may undergo low-temperature concentration to reduce its moisture content. Some plants also include a pasteurization step to prevent fermentation and crystallization.

Selecting the Right Honey Filling Machine

Your choice of equipment will be dictated by your plant's target output and operational scale.

For Small-Scale or Boutique Operations

A compact honey filling machine is the ideal solution for smaller production lines. These standalone units offer high efficiency for their size and often feature an adjustable filling height to accommodate various jar sizes.

For Large-Scale Commercial Plants

An inline honey filling machine is designed for high-volume plants. These systems typically feature two or four filling nozzles and can achieve a production capacity ranging from 3 to 6 tons per day, integrating seamlessly into a larger production line.

Understanding the Trade-offs

Choosing between a compact and an inline system involves balancing cost, complexity, and capacity.

The Cost of Scalability

Inline systems represent a significantly higher capital investment. They are built for scale, and their cost reflects their high throughput and integration capabilities.

Operational Complexity

A multi-nozzle inline system is more complex to operate, clean, and maintain than a simple compact machine. This requires more skilled labor and dedicated maintenance schedules.

Space and Infrastructure

Larger inline fillers demand more floor space and may have specific utility requirements. A compact machine offers much greater flexibility in plant layout and setup.

How to Choose Your Packing Solution

Match your equipment to your specific business goals to ensure an efficient and cost-effective operation.

- If your primary focus is starting small or running a boutique brand: A compact filling machine provides the necessary efficiency without the high upfront cost and complexity of a larger system.

- If your primary focus is maximizing output for an established commercial brand: An inline, multi-nozzle filling machine is essential to meet high production demands and scale your operation effectively.

Ultimately, the right packing solution seamlessly concludes your processing line and supports your specific production targets.

Summary Table:

| Packing Option | Best For | Daily Capacity | Key Consideration |

|---|---|---|---|

| Compact Filling Machine | Small-scale / Boutique operations | Limited by single nozzle | Lower cost, simple operation, flexible layout |

| Inline Filling Machine | Large-scale commercial plants | 3 to 6 tons | Higher throughput, integrated line, requires more space & skill |

Ready to streamline your honey packing process?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with robust, wholesale-focused honey processing and packing solutions. Whether you're scaling a boutique brand or maximizing output for a large commercial plant, our equipment ensures efficiency and reliability.

Contact our experts today to discuss the ideal filling machine for your production goals.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Commercial Rotary Honey Filling Machine for Production

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- Why must honey filling machinery use 316L stainless steel? Ensure Food Safety and Prevent Corrosion

- How does honey filling and packaging equipment contribute to the commercialization of bee products? Scaling Your Success

- What role do honey tasting kits and packaging equipment play in commercialization? Boost Your Brand and Market Value

- What is the role of automated filling and packaging equipment? Transform Bulk Honey into High-Value Retail Brands

- What role do automatic honey-filling machines play in the commercial packaging of honey? Scaling for Global Markets

- What role do honey filling machines play for high-yield crops? Optimize Your Italian Squash Honey Value Chain

- What are the advantages of using automated honey filling equipment? Scaling Your Commercial Honey Production

- How does the use of professional automated honey-filling machines benefit urban honey production? Scale Your Apiary