The single most important consideration when melting beeswax is that it is a flammable material with a low flashpoint. Therefore, you must use indirect, controlled heat to melt it safely and prevent both fire and severe burns. Never heat beeswax directly over an open flame or on a high-heat electric burner.

The core danger of melting beeswax isn't the wax itself, but the application of uncontrolled heat. Your primary goal is not just to melt the wax, but to meticulously manage its temperature from start to finish.

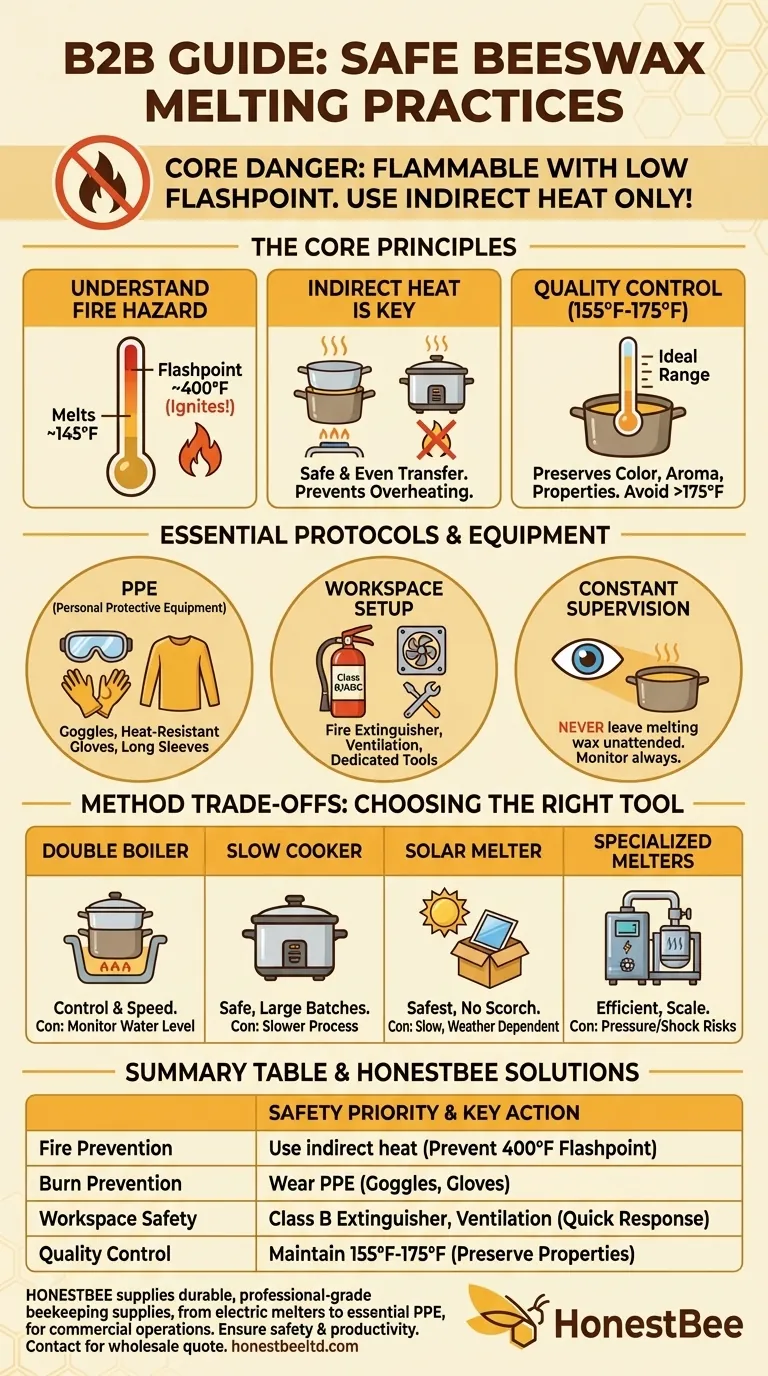

The Core Principles of Safe Melting

To work with beeswax safely, you must understand its physical properties. It’s not just about melting; it’s about controlling a combustible material.

Understanding the Fire Hazard

Beeswax is flammable. While its melting point is low (around 145°F or 63°C), its flashpoint—the temperature at which its vapors can ignite—is approximately 400°F (204°C).

Placing beeswax on a direct heat source, like a gas flame or an electric coil, creates hot spots that can easily exceed this temperature, leading to a dangerous wax fire.

The Importance of Indirect Heat

The professional standard for melting beeswax is indirect heat. This method uses a medium, typically water or air, to transfer heat gently and evenly.

Methods like a double boiler or a dedicated slow cooker (crock pot) are ideal. They create a buffer that prevents the wax from ever touching the primary heat source, making it nearly impossible to reach its flashpoint.

Maintaining Wax Quality with Temperature Control

Safety is not the only reason to control heat. Overheating beeswax, even if it doesn't cause a fire, will degrade its quality.

Heating wax much beyond 175°F (80°C) can darken its color, diminish its natural honey aroma, and potentially reduce its beneficial anti-microbial properties. Aim for a melting temperature between 155°F and 175°F.

Essential Safety Protocols and Equipment

Beyond the heating method, your personal safety and workspace setup are critical components of the process.

Your Personal Protective Equipment (PPE)

Splashes of hot wax can cause serious burns. Always wear appropriate PPE.

- Safety Goggles: Protect your eyes from unexpected splashes.

- Heat-Resistant Gloves: Allow you to handle hot containers safely.

- Long-Sleeved Shirt: Protects your arms from accidental contact or drips.

Setting Up Your Workspace

Prepare your environment before you begin melting.

- Fire Extinguisher: Keep a Class B or ABC fire extinguisher within easy reach.

- Ventilation: Work in a well-ventilated area to avoid inhaling fumes, especially if the wax is accidentally scorched.

- Dedicated Tools: Use pots, stir sticks, and containers exclusively for beeswax. This prevents contamination of kitchen utensils and makes cleanup far easier, as wax is difficult to remove completely.

The Rule of Constant Supervision

Never leave melting beeswax unattended. A double boiler can run out of water, or a thermostat on a slow cooker could fail. Constant monitoring ensures you can react immediately to any issue.

Understanding the Trade-offs: Common Melting Methods

Different methods offer varying levels of safety, convenience, and efficiency.

The Double Boiler Method

This involves placing a smaller pot containing the wax inside a larger pot of simmering water. It provides excellent, gentle heat control. The main trade-off is the need to constantly monitor the water level in the outer pot to ensure it doesn't boil away.

The Slow Cooker (Crock Pot) Method

A dedicated slow cooker is an extremely safe and effective method, especially for larger batches. The "low" or "warm" setting provides a stable, indirect heat source. While very safe, it is a slower melting process.

The Solar Melter

For beekeepers processing raw cappings, a solar melter is the safest possible option. It uses the sun's energy to gently melt the wax, guaranteeing it will not overheat or scorch. Its primary drawbacks are its slow speed and dependence on sunny weather.

Specialized Electric & Steam Melters

Larger-scale operations may use electric or steam-powered wax melters. While efficient, these introduce unique risks. Steam generators can build up dangerous pressure if overheated, and electric models carry a risk of shock if a heating element fails.

Making the Right Choice for Your Goal

Select your method based on your project's scale and your priorities.

- If your primary focus is small hobby projects: A double boiler offers a perfect balance of control and speed for tasks like making lip balms or a few candles.

- If your primary focus is processing larger batches: A dedicated slow cooker provides a safe, low-maintenance way to melt several pounds of wax at once.

- If your primary focus is maximum safety and wax purity: A solar melter is the ideal choice, especially for beekeepers who want the most gentle rendering method possible.

By treating beeswax with the respect a flammable material deserves, you can ensure a safe and successful outcome for any project.

Summary Table:

| Safety Priority | Key Action | Why It's Critical |

|---|---|---|

| Fire Prevention | Use indirect heat (double boiler, slow cooker) | Prevents wax from reaching its 400°F (204°C) flashpoint and igniting. |

| Burn Prevention | Wear safety goggles and heat-resistant gloves | Protects from serious injury caused by splashes of hot wax. |

| Workspace Safety | Keep a Class B fire extinguisher nearby and ensure good ventilation | Enables a quick response to a fire and avoids fume inhalation. |

| Quality Control | Maintain temperature between 155°F-175°F (68°C-80°C) | Prevents degrading the wax's color, scent, and beneficial properties. |

Melting wax safely requires the right equipment. Whether you're a hobbyist making candles or a commercial apiary processing hundreds of pounds of wax, HONESTBEE supplies the durable, professional-grade beekeeping supplies and equipment you need. From reliable electric melters to essential personal protective equipment (PPE), we help commercial beekeepers and distributors operate safely and efficiently at scale.

Ensure your operation's safety and productivity—contact our experts today for a wholesale quote.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

People Also Ask

- What factors should be considered when choosing a wax melter? Optimize Your Beekeeping Efficiency

- What are wax melters used for? Unlock Efficient Wax Processing for Your Business

- What are the safety precautions when working with melted beeswax? Prevent Burns and Fire Hazards

- What temperature range is considered gentle heat for melting beeswax? Preserve Aroma & Color

- What is the flash point of beeswax, and why is it important? Essential Safety Guide for Beekeepers