The primary safety considerations when using a wax melter revolve around the specific energy source it uses. The main risks include burns from high temperatures, pressure-related dangers with steam models, and the potential for electric shock from electric units.

Your choice of wax melter directly influences the safety protocols you must follow. While all models present a risk of burns, steam and electric melters introduce unique hazards—pressure and electricity—that demand specific operational awareness.

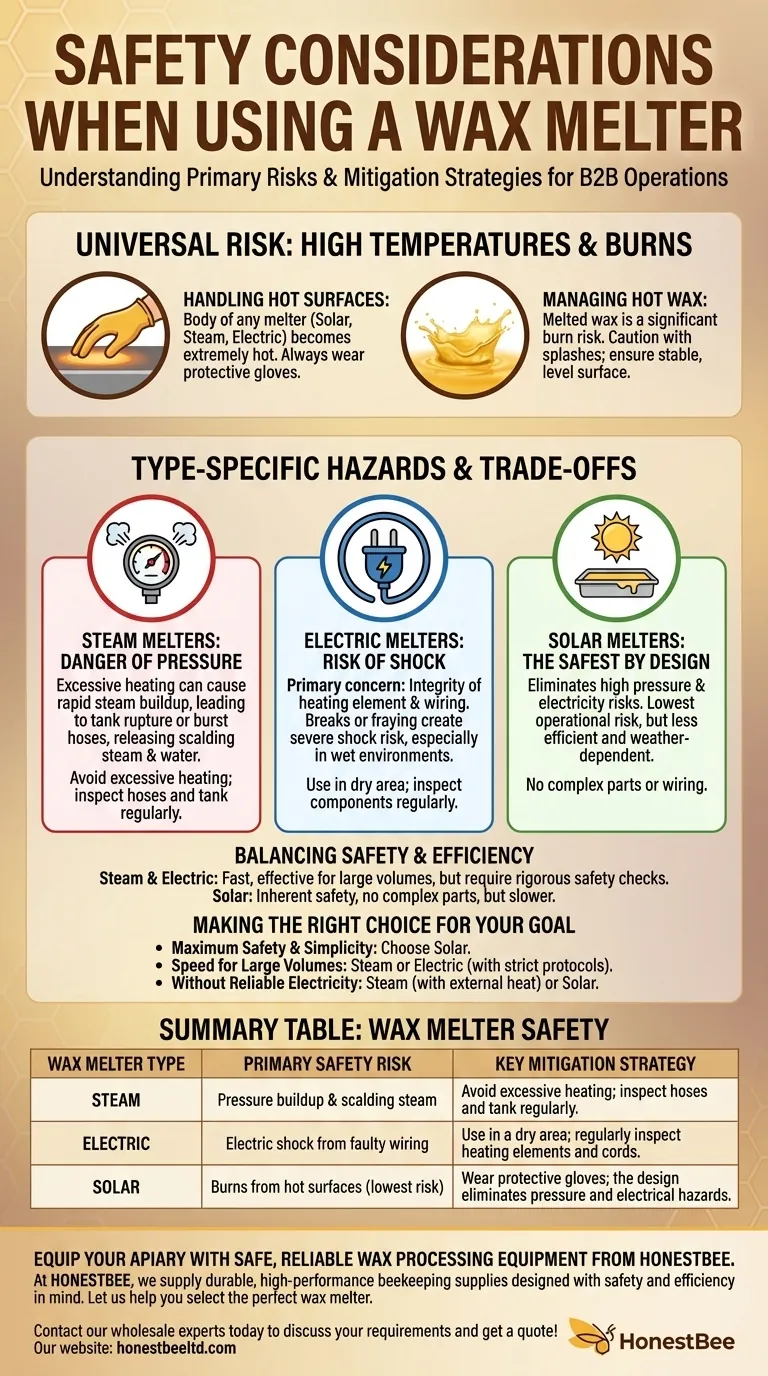

The Universal Risk: High Temperatures and Burns

Regardless of the type, all wax melters operate at temperatures high enough to cause serious burns. This is the most common hazard you will face.

Handling Hot Surfaces

The body of any wax melter, whether solar, steam, or electric, will become extremely hot during operation. Always wear protective gloves and avoid touching the unit with bare skin.

Managing Hot Wax

Melted wax itself is a significant burn risk. Be cautious of splashes when adding or moving wax, and ensure the melter is on a stable, level surface to prevent tipping and spills.

Type-Specific Hazards and How to Mitigate Them

Beyond general heat safety, each type of wax melter has distinct risks tied to its design. Understanding these is crucial for safe operation.

Steam Melters: The Danger of Pressure

Steam generators work by boiling water to create high-pressure steam. If this system is not managed correctly, it can become dangerous.

Excessive heating can cause a rapid buildup of steam pressure. This can lead to a rupture of the boiler tank or cause hoses to burst, releasing scalding steam and hot water.

Electric Melters: The Risk of Shock

Electric melters are convenient but introduce electrical hazards. The primary concern is the integrity of the heating element and wiring.

If an electric heating element breaks or the wiring becomes frayed, it can create a risk of severe electric shock, especially in the potentially wet environment of wax processing. Regularly inspect all electrical components.

Solar Melters: The Safest by Design

Solar wax melters are widely considered the safest option. They use the sun's energy, eliminating the risks of high pressure and electricity.

Their primary drawback is a lack of efficiency and dependence on weather, but from a purely hazard-focused perspective, they present the lowest operational risk.

Understanding the Trade-offs: Safety vs. Efficiency

Choosing a wax melter involves balancing your need for performance against your tolerance for risk and your working environment.

The Power of Steam and Electric Models

Steam and electric melters are popular because they are fast and effective, capable of processing large quantities of wax regardless of the weather. This efficiency comes with the responsibility of managing pressure and electrical systems safely.

The Simplicity of Solar Models

A solar melter's lower efficiency is the direct trade-off for its inherent safety. It has no complex parts, no pressure, and no electrical wiring, making it simple and reliable, albeit slower.

Your Environment Matters

The choice also depends on your workspace. An electric melter requires a dry, safe area with proper electrical grounding. A steam melter is often used outdoors due to the heat and steam it produces.

Making the Right Choice for Your Goal

Select your equipment based on a clear understanding of its operational demands and your own priorities.

- If your primary focus is maximum safety and simplicity: Choose a solar wax melter, as it eliminates pressure and electrical hazards.

- If your primary focus is speed for processing large volumes: A steam or electric model is more effective, but you must commit to rigorous safety checks and proper operating procedures.

- If you are working without reliable access to electricity: A steam melter (with an external heat source like propane) or a solar melter are your most practical options.

By understanding the risks inherent to each design, you can operate your chosen wax melter with confidence and control.

Summary Table:

| Wax Melter Type | Primary Safety Risk | Key Mitigation Strategy |

|---|---|---|

| Steam | Pressure buildup & scalding steam | Avoid excessive heating; inspect hoses and tank regularly. |

| Electric | Electric shock from faulty wiring | Use in a dry area; regularly inspect heating elements and cords. |

| Solar | Burns from hot surfaces (lowest risk) | Wear protective gloves; the design eliminates pressure and electrical hazards. |

Equip your apiary with safe, reliable wax processing equipment from HONESTBEE.

Choosing the right wax melter is critical for protecting your team and your investment. At HONESTBEE, we supply commercial apiaries and distributors with durable, high-performance beekeeping supplies designed with safety and efficiency in mind.

Let us help you select the perfect wax melter for your operational needs and safety standards. Contact our wholesale experts today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

People Also Ask

- Can I melt beeswax in a wax melter? The Key to Safe, High-Quality Results

- What are the design advantages of a double-jacketed Beeswax Melting Tank? Ensure Superior Wax Quality and Purity

- How does a professional solar wax melter improve the efficiency of beeswax processing? Maximize Purity & Lower Costs

- What is the general procedure for operating a wax melter? Safe and Efficient Wax Melting Guide

- What happens to the honeycomb material after the honey has been extracted? Unlock the Value of Wax

- What is the function of professional beeswax purification and refining equipment? Boost Trade Value & Purity

- How does the solar waxing machine operate without electricity or fuel? Harnessing the Sun's Power for Pure Beeswax

- Why is the use of fine filtration media such as felt or cotton cloth necessary when purifying crude beeswax?