At its core, honey filtration involves two primary types of systems: simple mesh filters and more complex multi-stage filters. Mesh filters, typically made of fine fabric, are best suited for hobbyists and small-scale producers to remove large debris like wax and bee parts. Multi-stage systems are used in commercial operations, employing a series of progressively finer filters to achieve maximum purity and clarity for a mass-market product.

The choice of a honey filter is not merely about removing impurities. It is a fundamental decision that balances the desired level of visual clarity against the preservation of the honey's natural compounds, such as pollen, which directly impacts its character and market positioning.

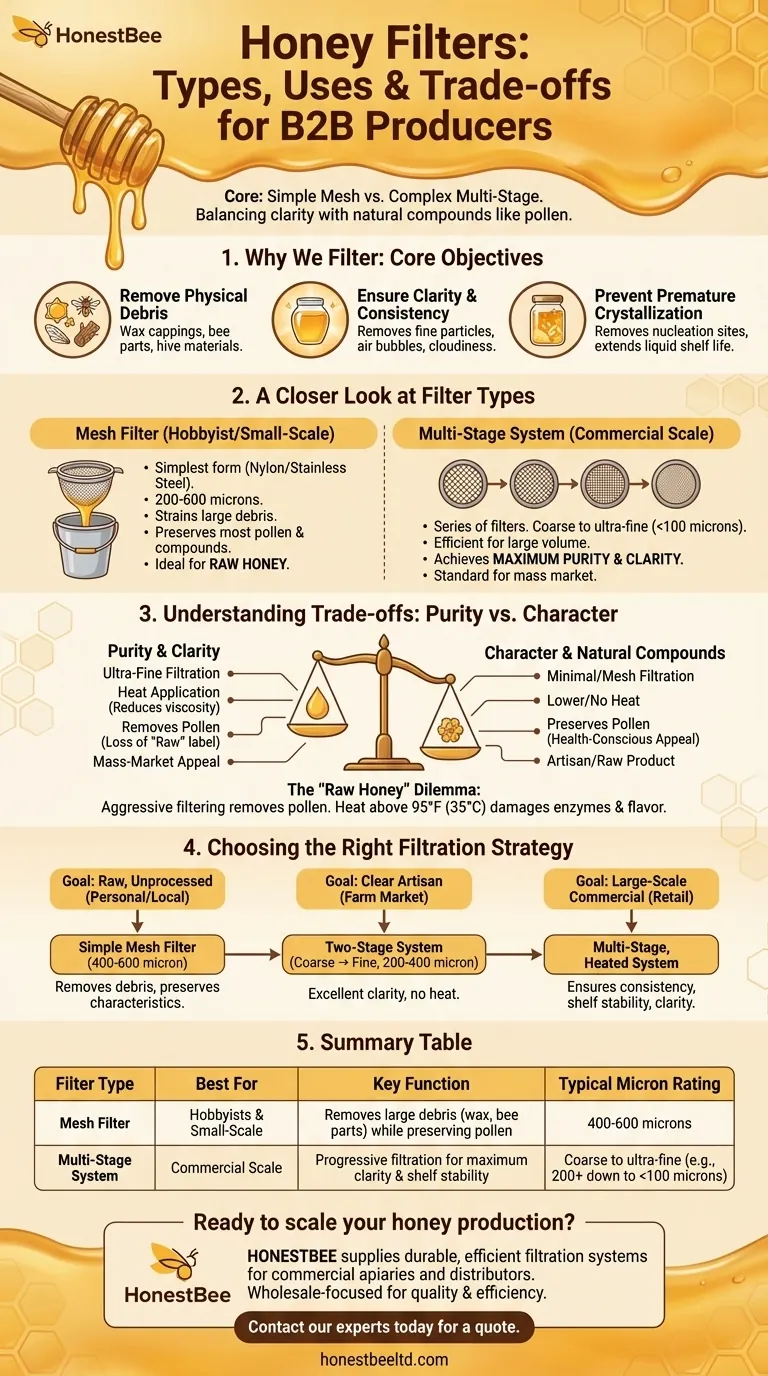

Why We Filter Honey: The Core Objectives

Before choosing a filter, it is essential to understand the goals of the filtration process. The objective is not simply "cleaning" but achieving a specific outcome for the final product.

Removing Physical Debris

The most immediate goal is to remove visible, unwanted materials from the honey after extraction. This includes bits of wax cappings, wood splinters from the hive frames, and unfortunately, occasional bee parts. This step is non-negotiable for any level of production.

Ensuring Clarity and Consistency

For many consumers, visual appeal matters. Filtration removes fine particles, such as suspended pollen grains and air bubbles, which can make honey appear cloudy. For commercial producers, this step is critical for creating a consistent, shelf-stable product that meets market expectations.

Preventing Premature Crystallization

Fine, suspended particles can act as nucleation sites, encouraging sugar crystals to form more rapidly. By filtering these particles out, you can extend the honey's liquid state, which is a key factor for retail shelf life.

A Closer Look at the Filter Types

The method you choose is determined almost entirely by the scale of your operation and the characteristics you want in your final product.

The Mesh Filter: The Go-To for Hobbyists

A mesh filter is the simplest form of filtration. It is often a nylon bag or a stainless steel screen with a specific micron rating (e.g., 200 to 600 microns) that fits over a bucket or tank.

It excels at straining out the largest particles—wax, wood, and other field debris—while allowing the vast majority of pollen and other natural compounds to pass through. This makes it the ideal choice for producing raw or minimally processed honey.

The Multi-Stage System: The Standard for Commercial Scale

A multi-stage system is not a single filter but a series of them. Honey is passed through screens of progressively finer mesh, starting with a coarse filter and ending with a very fine one.

This setup is designed for efficiency in larger operations. The initial stages remove the large debris that would quickly clog finer filters, allowing for a continuous and effective process. This method ensures maximum purity and a brilliantly clear final product.

Understanding the Trade-offs: Purity vs. Character

The decision to filter more aggressively introduces critical trade-offs that every producer must consider. More filtration is not always better.

The "Raw Honey" Dilemma

Many health-conscious consumers specifically seek out honey that contains its natural pollen. Aggressive or ultra-fine filtration, sometimes called "pressure filtering," can remove nearly all pollen from the honey. While this creates a very clear product, it can no longer be marketed as "raw" and loses a key selling point for a significant audience.

The Impact of Heat

Honey is highly viscous, or thick. To force it through very fine filters efficiently, commercial producers often heat it to lower its viscosity. However, heating honey above hive temperature (around 95°F or 35°C) can destroy beneficial enzymes and alter its delicate flavor and aroma profile.

Balancing Act for Quality

The best producers find a balance. They use just enough filtration to create a clean, appealing product without stripping the honey of the very components that make it unique and flavorful. This often means avoiding excessive heat and using the coarsest filter possible that still achieves their quality goal.

Choosing the Right Filtration Strategy

Your choice should be a deliberate one, directly aligned with the type of honey you want to produce and the market you want to serve.

- If your primary focus is producing raw, unprocessed honey for personal use or a local market: A simple, single-stage mesh filter (400-600 micron) is all you need to remove debris while preserving all natural characteristics.

- If your primary focus is creating a clear, artisan product for farm markets: A two-stage system, using a coarse screen followed by a finer mesh filter (200-400 micron), will deliver excellent clarity without requiring heat.

- If your primary focus is large-scale commercial production for retail: A multi-stage, heated filtration system is necessary to ensure product consistency, shelf stability, and the visual clarity expected by mass-market consumers.

Ultimately, effective honey processing is about making an informed choice that honors the product and meets your specific goals.

Summary Table:

| Filter Type | Best For | Key Function | Typical Micron Rating |

|---|---|---|---|

| Mesh Filter | Hobbyists & Small-Scale | Removes large debris (wax, bee parts) while preserving pollen | 400-600 microns |

| Multi-Stage System | Commercial Scale | Progressive filtration for maximum clarity and shelf stability | Coarse to ultra-fine (e.g., 200+ down to <100 microns) |

Ready to scale your honey production with professional-grade equipment?

At HONESTBEE, we supply durable and efficient honey filtration systems designed for the demands of commercial apiaries and beekeeping equipment distributors. Our wholesale-focused operations ensure you get the right equipment to maintain honey quality, improve efficiency, and meet market expectations.

Contact our experts today to discuss your specific needs and get a quote on our reliable beekeeping supplies.

Visual Guide

Related Products

- Professional Stainless Steel Honey Filter with Support Handle

- Professional Honey Filter with Tripod Support Stand

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Two-Stage Plastic Honey Filter for Buckets

People Also Ask

- How does a stainless steel filtration system protect product quality? Ensure Purity & Stability in Honey Processing

- What is the function of disposable filtration consumables? Ensure Pure, Market-Ready Honey for Retail Excellence

- What are the technical advantages of using professional filtration for honey? Optimize Clarity and Quality

- How should honey filtering equipment be maintained? Essential Care for Longevity and Purity

- Why is a funnel equipped with a filter mesh necessary during the primary processing of forest honey?