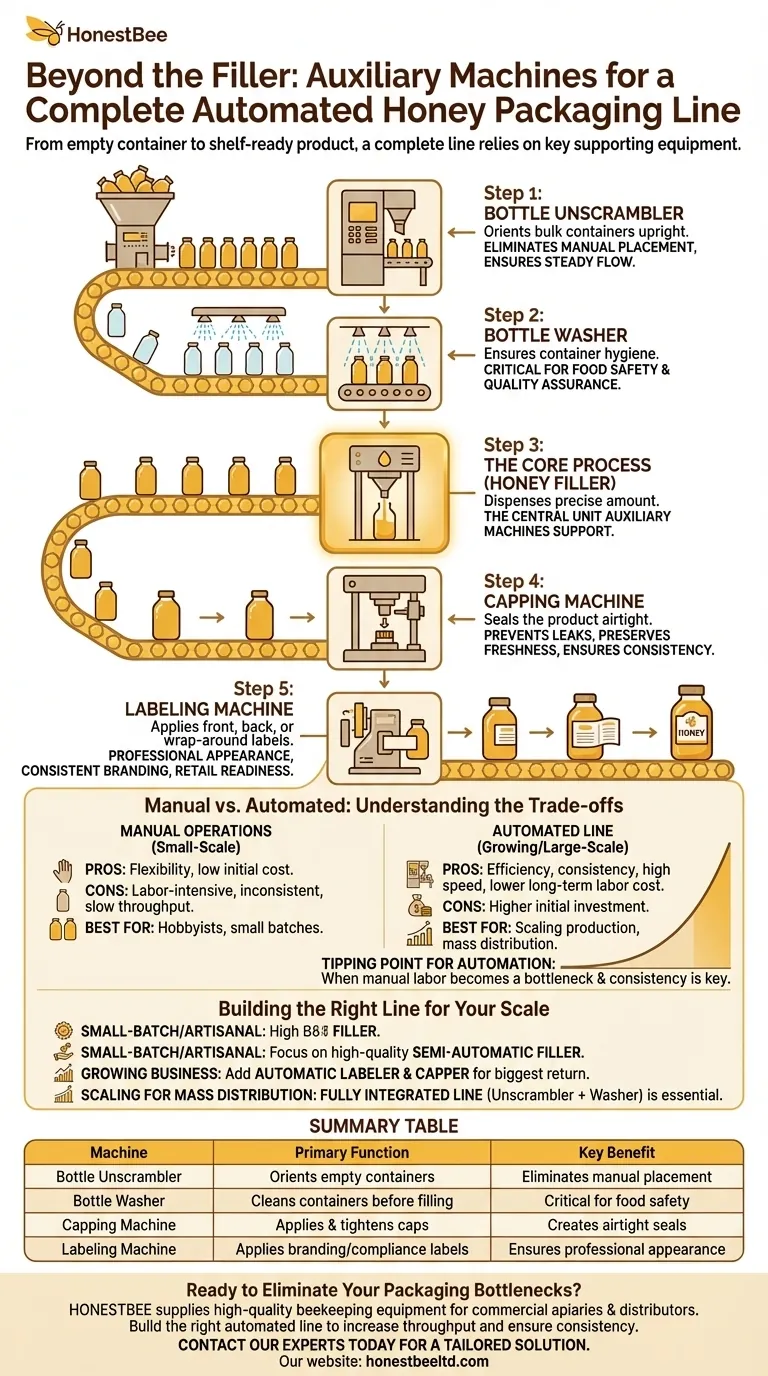

Beyond the filler itself, a complete honey packaging line relies on several key auxiliary machines to automate the process from start to finish. The primary supporting equipment includes a bottle unscrambler for sorting, a bottle washer for sanitation, a capping machine for sealing, and a labeling machine for branding and compliance. These components work in sequence to create an efficient, integrated production system.

A honey filler is just one part of a larger, integrated system. The auxiliary machines—unscrambler, washer, capper, and labeler—are not optional add-ons but essential components that automate the entire process from empty container to shelf-ready product.

The Automated Honey Packaging Workflow

Viewing the packaging process as a sequential workflow is the best way to understand the role of each machine. Each station prepares the product for the next, minimizing manual intervention and maximizing throughput.

Step 1: Preparing the Containers (Bottle Unscrambler)

A bottle unscrambler is the starting point of an automated line. It takes bulk containers—which are often supplied jumbled in large bags or boxes—and automatically orients them upright onto the conveyor belt.

This machine eliminates the slow, labor-intensive process of manually placing each bottle on the line, creating a steady and consistent flow of containers for the subsequent stages.

Step 2: Ensuring Hygiene (Bottle Washing Machine)

Before filling, a bottle washing machine ensures the container is perfectly clean. It typically uses high-pressure air, sanitized water, or other methods to remove any dust, debris, or potential contaminants from the manufacturing or shipping process.

This step is critical for food safety and quality assurance, guaranteeing that the honey is packaged in a sterile environment.

Step 3: The Core Process (Honey Filler)

Following the cleaning stage, the bottles move to the honey filling machine. This is the central unit the auxiliary machines are built to support. It dispenses a precise, predetermined amount of honey into each container.

Step 4: Sealing the Product (Capping Machine)

Once filled, the containers immediately move to an automatic capping machine. This device applies the cap and tightens it to the correct torque specification.

Proper capping ensures an airtight seal, which is vital for preventing leaks, protecting the honey from contamination, and preserving its freshness. It provides a level of consistency that is difficult to achieve with manual capping.

Step 5: Finalizing for Market (Labeling Machine)

The final step in the automated process is the labeling machine. It accurately applies front, back, or wrap-around labels to each container.

This machine ensures a professional appearance and consistent brand presentation. It is also essential for displaying required information such as nutritional facts, ingredients, and barcodes for retail.

Understanding the Trade-offs: Manual vs. Automated

While a fully automated line is highly efficient, it is not the right choice for every operation. The decision to invest in auxiliary machinery depends entirely on production scale and business goals.

The Case for Manual Operations

For small-scale or hobbyist producers, the initial investment in a full line can be prohibitive. At this scale, it is often more practical to perform washing, capping, and labeling by hand.

Manual processes offer flexibility, especially when dealing with small batches, unique container shapes, or frequent product changeovers.

The Tipping Point for Automation

Businesses typically invest in auxiliary machines when manual labor becomes a bottleneck. As production volume increases, the cost and inconsistency of manual work begin to outweigh the initial capital investment in automation.

If you cannot fill bottles as fast as your staff can cap or label them (or vice versa), it is time to consider automating the slowest part of your process. Key drivers include reducing labor costs, improving product consistency, and meeting the quality standards required by larger distributors.

Building the Right Production Line for Your Scale

Choosing which machines to invest in is a strategic decision that should align with your production needs.

- If your primary focus is small-batch, artisanal production: A high-quality semi-automatic filler is your most important investment; the auxiliary steps can remain manual to control costs.

- If your primary focus is growing your business: After the filler, an automatic labeler and capper often provide the biggest return by eliminating the most time-consuming manual tasks.

- If your primary focus is scaling for mass distribution: A fully integrated line, including a bottle unscrambler and washer, is essential for achieving the speed, efficiency, and compliance required for large retail markets.

Ultimately, building an effective production line is about systematically identifying and eliminating your biggest constraints to growth.

Summary Table:

| Machine | Primary Function | Key Benefit |

|---|---|---|

| Bottle Unscrambler | Orients empty containers upright onto conveyor | Eliminates manual bottle placement, ensures steady flow |

| Bottle Washer | Cleans containers before filling | Critical for food safety and quality assurance |

| Capping Machine | Applies and tightens caps automatically | Creates airtight seals for freshness and consistency |

| Labeling Machine | Applies branding and compliance labels | Ensures professional appearance and retail readiness |

Ready to Eliminate Your Packaging Bottlenecks?

HONESTBEE supplies the high-quality beekeeping supplies and equipment that commercial apiaries and distributors rely on. Whether you are a growing commercial apiary or a beekeeping equipment distributor, we can help you build the right automated packaging line to increase your throughput, ensure product consistency, and meet the demands of large-scale distribution.

Contact our experts today to discuss your specific needs and get a tailored solution for your operation.

Visual Guide

Related Products

- Automated Rotary Bottle Unscrambler for Honey Production Line

- Fully Automatic High Speed Centrifugal Bottle Unscrambler

- Semi Automatic Round Bottle Labeling Machine

- Automatic In-Line Round Bottle Labeling Machine

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

People Also Ask

- What are the advantages of using automated honey filling equipment? Protect Honey Quality and Physicochemical Integrity

- What role does commercial filling and sealing equipment play in stingless bee honey? Secure Quality & Stability

- Why is precision honey filling equipment critical for competitiveness? Secure Market Authority with Advanced Packaging

- What technical advantages do automated honey filling and packaging machines provide? Elevate Your Retail Compliance

- What are the contributions of professional honey filling and packaging machinery to the retail supply chain?

- Why are professional-grade honey filling machines necessary? Boost Accuracy and Hygiene in Commercial Production

- What is the importance of professional honey-filling machines? Scale Your Cooperative for the Wholesale Market

- What material should a honey-filling machine be made from? Ensure Safety with Food-Grade Stainless Steel