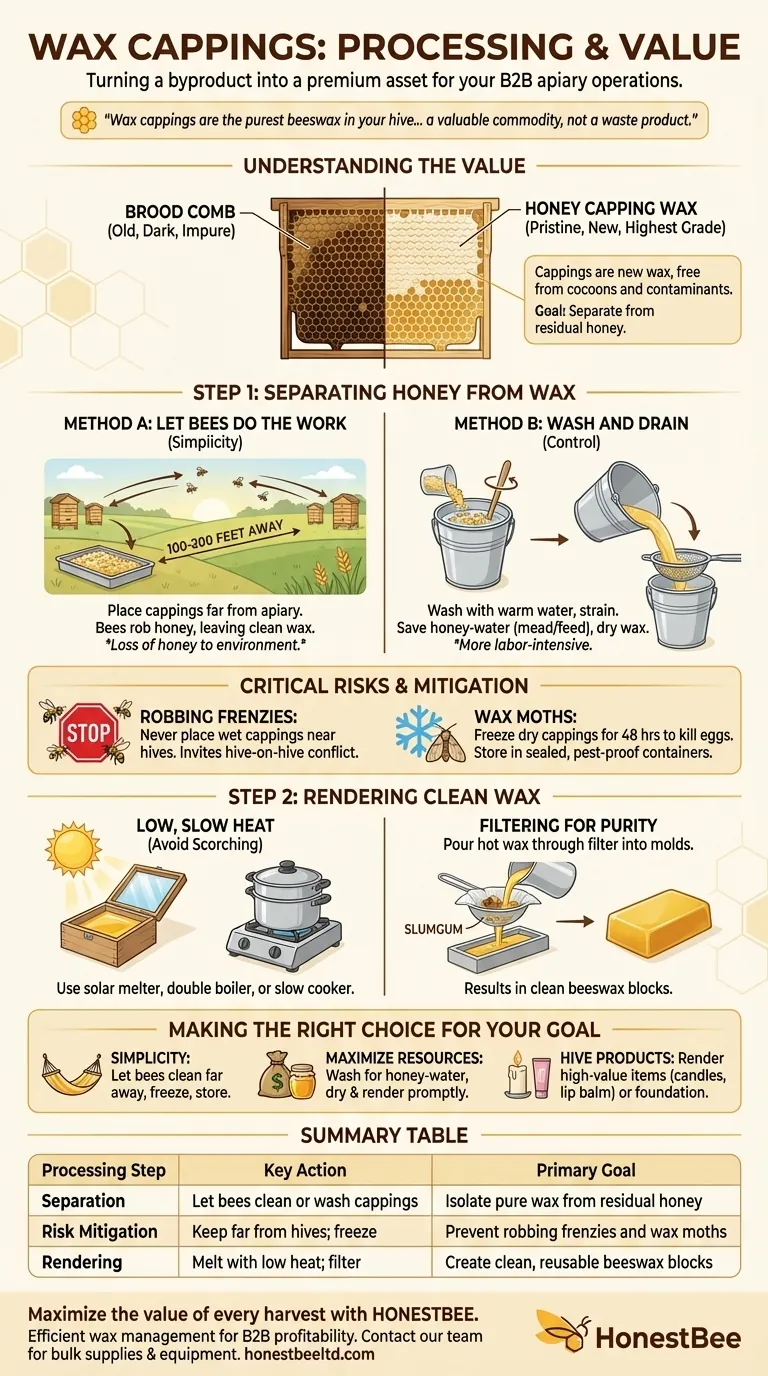

After harvesting honey, you are left with wax cappings, a sticky mixture of pure beeswax and residual honey. Your primary goal is to separate these two valuable components. You can either let your bees clean the cappings for you or wash them yourself, after which the clean, dry wax should be stored and eventually melted down for reuse.

Wax cappings are the purest beeswax in your hive, making them a valuable commodity, not a waste product. The core task is to efficiently separate the wax from the remaining honey and then render it into clean blocks for use in candles, cosmetics, or new hive foundations.

Understanding the Value of Wax Cappings

Before you process them, it's critical to understand why cappings are considered a premium product by beekeepers.

Why Cappings are the Highest Quality Wax

Bees use wax for two main purposes: building comb for brood (raising young bees) and capping honey for storage. Brood comb is reused many times, becoming darker and absorbing impurities over the years.

In contrast, the wax used to cap honey is brand new. It is pristine, light in color, and free from the cocoons and contaminants found in old brood comb, making it the highest grade of wax your hive produces.

The Immediate Goal: Separation

Your cappings are a mix of two things you want: honey and wax. The first and most important step in processing is to separate them. Any honey left on the wax when you melt it will scorch, darken the wax, and complicate the rendering process.

Step 1: Separating Honey from the Wax

You have two primary methods for getting the last bits of honey off your cappings. Each has its own benefits and drawbacks.

Method A: Let the Bees Do the Work

You can allow bees to "rob" the honey from the cappings. To do this, spread the cappings in a single layer on a baking sheet or shallow tray.

Place this tray at least 100-200 feet away from your apiary. The bees will find it and carry the honey back to their hives, leaving you with clean, dry wax.

Method B: Wash and Drain

A more controlled method is to wash the cappings yourself. Place the cappings in a bucket and cover them with warm (not hot) water. Stir to dissolve the honey off the wax.

Pour the mixture through a strainer or colander. The honey-water can be saved to make mead or used as a supplemental feed for your bees, while the wax is rinsed and set out to dry completely.

Understanding the Trade-offs and Risks

Choosing a method requires understanding the potential pitfalls, especially regarding the health and safety of your apiary.

The Critical Risk of Robbing Frenzies

Never place wet cappings near your hives. Doing so invites a "robbing frenzy," where bees from strong hives attack weaker ones to steal their resources. This creates chaos, leads to dead bees, and can quickly spread pests and diseases throughout your apiary. Keeping the feeding station far away turns it into a general foraging source, not a target for hive-on-hive conflict.

The Pest Problem: Wax Moths

Wax cappings, whether cleaned or not, are a prime target for wax moths. If you are not rendering the wax immediately, you must freeze the cappings for at least 48 hours. This kills any existing moth eggs or larvae. After freezing, you can store the dry cappings in a sealed, pest-proof container until you've collected enough to process.

Control vs. Simplicity

Letting the bees clean the cappings is simple and requires little work. However, you lose the residual honey to the environment.

Washing the cappings is more labor-intensive but gives you maximum control. It allows you to recover all the honey and ensures the cleaning process happens on your schedule.

Step 2: Rendering Your Clean Wax

Once your wax is clean and completely dry, you can melt it down into usable blocks. This process is called rendering.

Melting the Wax

The key to rendering is low, slow heat to avoid scorching the wax. The two most common methods are using a dedicated solar wax melter or a double boiler on a stovetop. A slow cooker (like a Crock-Pot) set to low can also work well.

Filtering for Purity

As the wax melts, impurities and debris (known as "slumgum") will either sink to the bottom or float on top.

For the cleanest final product, pour the hot, liquid wax through a filter like cheesecloth, a paper towel, or an old t-shirt into a mold. Molds can be silicone baking pans or even clean, empty milk cartons. Once cooled, you will have a clean, solid block of pure beeswax.

Making the Right Choice for Your Goal

Your approach to handling wax cappings should align with your beekeeping philosophy and available time.

- If your primary focus is simplicity and minimal effort: Let the bees clean the cappings far from the apiary, then freeze and store the dry wax until you have enough to render a large batch at once.

- If your primary focus is maximizing resources: Wash the cappings to create honey-water for mead or feed, and then promptly dry and render the wax to prevent pest issues.

- If your primary focus is creating hive products: Render your cappings into clean blocks to make high-value items like candles, lip balms, or wood polish, or trade it for new wax foundation.

By properly processing your cappings, you transform a messy byproduct of your harvest into one of your apiary's most valuable assets.

Summary Table:

| Processing Step | Key Action | Primary Goal |

|---|---|---|

| Separation | Let bees clean or wash cappings | Isolate pure wax from residual honey |

| Risk Mitigation | Keep cappings far from hives; freeze to kill pests | Prevent robbing frenzies and wax moth infestation |

| Rendering | Melt wax with low, slow heat; filter through cheesecloth | Create clean, reusable beeswax blocks |

Maximize the value of every harvest with HONESTBEE.

As a commercial apiary or beekeeping equipment distributor, efficient wax management is key to profitability. Our wholesale-focused operations supply the durable equipment you need to process wax cappings effectively—from solar wax melters to filtering supplies.

Let us help you turn this premium byproduct into a significant revenue stream. Contact our team today to discuss your bulk supply needs and optimize your entire honey harvesting operation.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- HONESTBEE 4 Frame Manual Self Reversing Honey Extractor for Beekeeping

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

People Also Ask

- What is the flashpoint of beeswax? Essential Safety and Quality Tips for Beekeepers

- How do water jacket melters function? Achieve Gentle, Scorch-Free Melting for Sensitive Materials

- What is the best way to melt beeswax for candles? The Safest Method for Professional Results

- What role do precision wax melting units and molds play? Professional Beeswax Processing & Crafting Guide

- What are the features of industrial wax melters? Unlock Precision Purity for Commercial Beeswax Production