When selecting a honey bucket heater, the most critical factors are its ability to provide gentle, uniform heat, precise temperature control, and physical compatibility with your specific containers, including any gate valves. These features work together to protect the delicate quality of your honey.

The goal is not simply to heat honey, but to manage its viscosity and prevent crystallization without destroying its natural enzymes and flavor. The right heater is a tool for preservation, prioritizing gentle, even warmth over raw heating power.

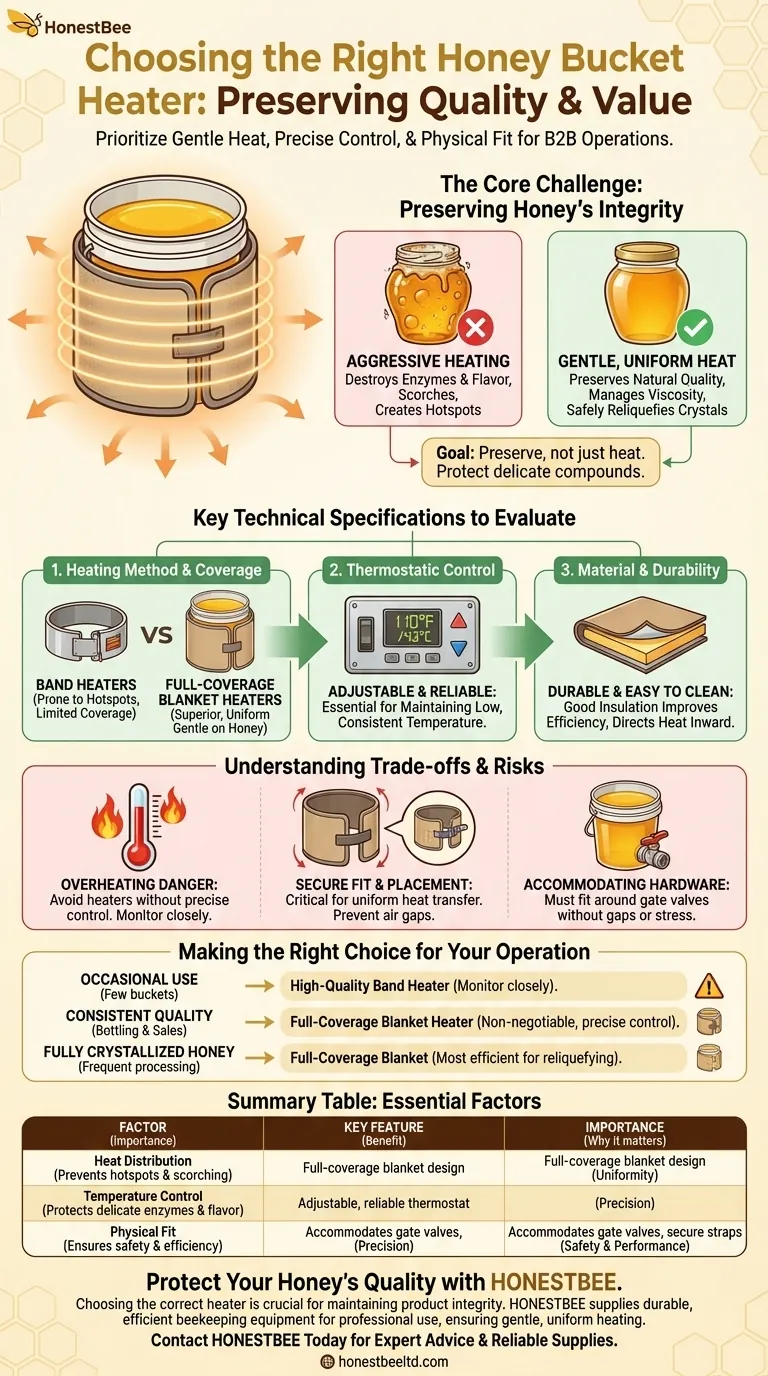

The Core Challenge: Preserving Honey's Integrity

Honey is a sensitive product. Aggressive or uneven heating can permanently damage its quality by destroying beneficial enzymes and altering its flavor profile. Understanding this is key to choosing the right tool.

Why Precise Temperature is Non-Negotiable

Honey's delicate enzymes, aroma, and flavor compounds are easily degraded by high temperatures.

A quality heater with an adjustable thermostat is essential. This allows you to maintain a low, consistent temperature—typically just enough to reliquefy crystals or improve flow without "cooking" the product.

The Problem of Hotspots

Uneven heating creates "hotspots" where parts of the honey become overheated while other parts remain cool.

This localized overheating can scorch the honey, destroying its quality. Therefore, a heater's ability to provide uniform heat distribution across the entire surface of the container is its most important technical feature.

Combating Crystallization

Crystallization is a natural process that does not harm honey but makes it difficult to pour and package.

Gentle, controlled heat safely melts these crystals, returning the honey to a liquid state without compromising its inherent goodness.

Key Technical Specifications to Evaluate

Beyond the basic principles, you must assess the specific design and features of any heater you consider.

Heating Method and Coverage

Heaters typically come in two main styles: band heaters and full-coverage blanket heaters.

Band heaters are simpler and wrap around a small section of the bucket. They are often less expensive but are more prone to creating hotspots.

Blanket heaters wrap around the entire container, providing broader and more even heat distribution. This is the superior method for protecting honey quality.

Thermostatic Control

A reliable, built-in thermostat is not optional; it is a core requirement.

Look for a heater with a clearly marked and adjustable temperature range. This gives you direct control over the process, ensuring you can apply the minimum heat necessary.

Material and Durability

The heater will be used in a working environment, so its construction matters.

Ensure the materials are durable and easy to clean. Good insulation will also improve the heater's efficiency, reducing energy consumption and ensuring heat is directed into the honey, not the surrounding air.

Understanding the Trade-offs and Risks

Choosing the wrong heater, or using a good one improperly, carries significant risks to both your product and your safety.

The Danger of Overheating

The single biggest risk is overheating the honey. This can happen with a heater that lacks precise controls or is too powerful for the container size.

Always start at the lowest effective temperature and monitor the honey's state. Never leave a heater unattended for extended periods.

Secure Fit and Placement

A loose-fitting heater is inefficient and dangerous. It creates air gaps that prevent uniform heat transfer, leading to hotspots.

A heater with a secure placement strap or fastening system is critical. It ensures the heating element maintains full contact with the bucket's surface for safe and effective operation.

Accommodating Hardware

Many honey buckets are fitted with a gate valve near the bottom for dispensing.

Your heater must be designed to fit around this hardware without creating large gaps or putting stress on the valve. A poorly fitting heater can be a safety hazard and will perform poorly.

Making the Right Choice for Your Operation

Select a heater based on your operational needs, always prioritizing the preservation of your honey's quality.

- If your primary focus is occasional use for a few buckets: A high-quality band heater with a reliable thermostat can work, provided you monitor it closely to prevent overheating.

- If your primary focus is consistent quality for bottling and sales: A full-coverage blanket heater with precise, adjustable temperature control is a non-negotiable investment.

- If you frequently deal with fully crystallized honey: Prioritize a full-coverage blanket to ensure the most efficient and uniform heat transfer for safely reliquefying the entire container.

Ultimately, choosing the right heater is a direct investment in the quality and value of your final product.

Summary Table:

| Factor | Importance | Key Feature |

|---|---|---|

| Heat Distribution | Prevents hotspots & scorching | Full-coverage blanket design |

| Temperature Control | Protects delicate enzymes & flavor | Adjustable, reliable thermostat |

| Physical Fit | Ensures safety & efficiency | Accommodates gate valves, secure straps |

Protect your honey's quality and value with the right equipment from HONESTBEE.

Choosing the correct honey bucket heater is crucial for commercial apiaries and distributors to maintain product integrity during processing. HONESTBEE supplies durable, efficient beekeeping equipment designed for professional use, ensuring gentle, uniform heating that preserves your honey's natural enzymes and flavor.

Let our wholesale-focused team help you select the ideal heater for your operation's scale and needs. Contact HONESTBEE today for expert advice and reliable beekeeping supplies.

Visual Guide

Related Products

- Silicone Rubber Honey Drum Heating Belt

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- Stainless Steel Triangle Support Honey Strainer and Filters

- Stainless Steel Pail Perch Bucket Bench

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- What is the primary function of a honey heating tank? Master Your Honey Processing with Precision Control

- What is the purpose of heating honey during processing? Optimize Flow, Filtration, and Shelf Stability Efficiently

- What happens if you heat up honey? The Impact on Enzymes, Flavor, and Quality

- In what ways does a honey heating tank improve efficiency and save time? Master Viscosity for Faster Production

- What makes honey heating tanks versatile for different processing needs? Master Efficient Honey Production

- What is the purpose of an external heater for the storage tank in a honey drying system? Boost Dehydration Efficiency

- How do honey super warmers assist in the honey bottling and filtering process? Boost Your Efficiency Today

- What is the primary function of sugar solution heating equipment? Scale Your Commercial Apiary Feeding Efficiency