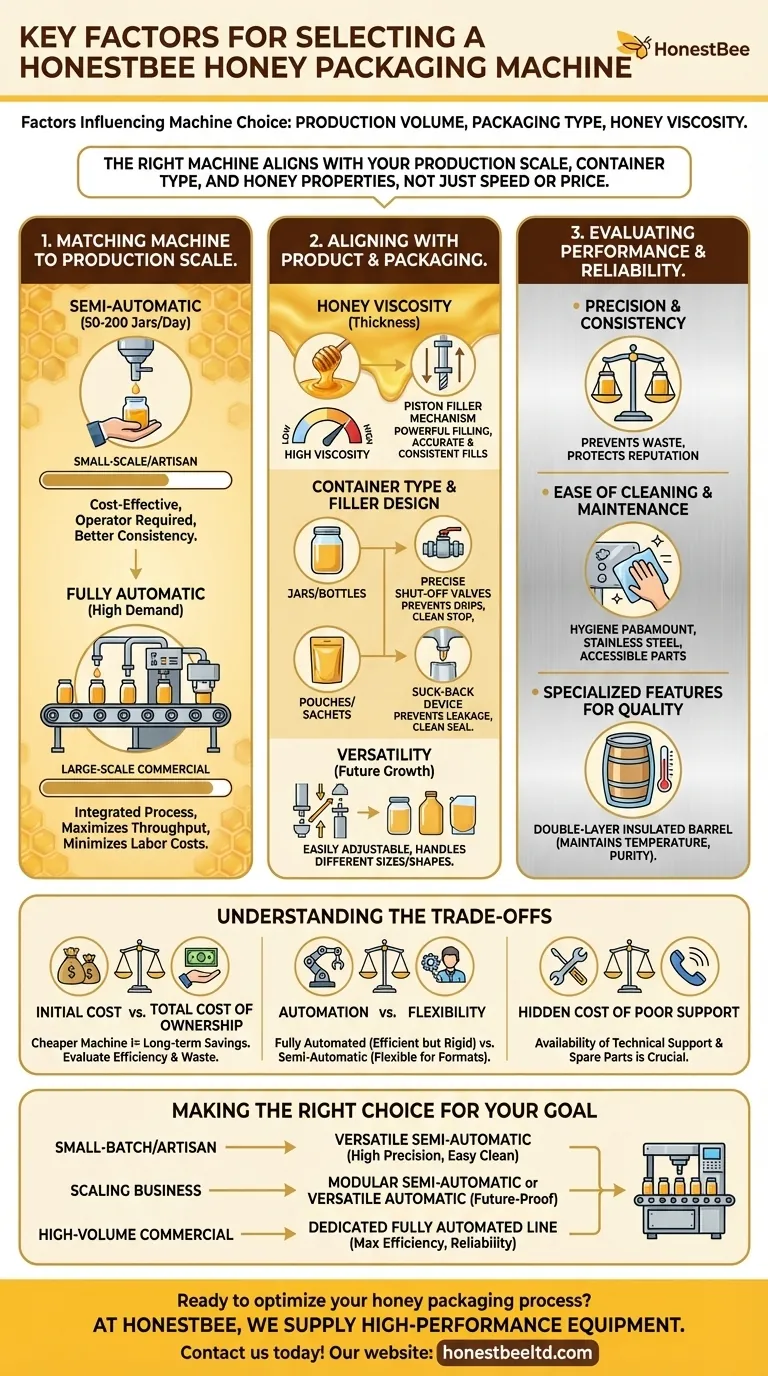

The key factors in selecting a honey packaging machine are your production volume, the type of packaging you use, and the viscosity of your honey. These three elements directly influence the required machine speed, precision, versatility, and overall cost-effectiveness, ensuring the equipment you choose is a perfect fit for your operational needs.

The most common mistake is focusing solely on speed or price. The right machine is not the fastest or the cheapest; it's the one that aligns perfectly with your production scale, container type, and the unique properties of your honey.

Matching the Machine to Your Production Scale

The first decision point is determining the level of automation that matches your output. This choice has the single biggest impact on cost, efficiency, and labor requirements.

Semi-Automatic for Small-Scale Operations

For small-scale or artisan producers, a semi-automatic machine is often the most practical starting point. These systems are ideal for operations filling between 50 and 200 jars per day.

They require an operator to place containers and activate the filling process but offer a significant step up from manual methods in terms of consistency and speed.

Fully Automatic for Large-Scale Producers

Large-scale commercial producers require fully automated systems to meet high demand. These machines integrate the entire process from start to finish.

A conveying system moves containers through filling, capping, and labeling stations without manual intervention, maximizing throughput and minimizing labor costs per unit.

Aligning with Your Product and Packaging

Not all honey is the same, and neither are packaging containers. The machine's mechanical design must be compatible with your specific product and the containers you use to sell it.

The Critical Role of Honey Viscosity

The viscosity (thickness) of your honey is a critical technical consideration. Thicker, more viscous honey requires a machine with a more powerful filling mechanism, such as a piston filler, to ensure accurate and consistent fills without creating air pockets.

Filler Design for Different Containers

If you use jars or bottles, look for a machine with precise shut-off valves at the filling nozzle. This feature prevents drips and ensures a clean stop once the target fill level is reached.

For pouches or sachets, a feature like a suck-back device is essential. This mechanism pulls a small amount of honey back into the nozzle after each fill, preventing leakage and ensuring a clean seal.

Versatility for Future Growth

Consider a machine's versatility and adaptability. A system that can easily be adjusted to handle different sizes and shapes of containers provides flexibility to introduce new product lines without a major new investment.

Evaluating Machine Performance and Reliability

Beyond basic function, the machine's daily performance and long-term reliability determine its true value. These factors impact product quality, waste, and operational downtime.

Precision and Consistency

High precision is non-negotiable. Consistent fill volumes prevent product waste from overfilling and protect your brand's reputation from underfilled containers.

Ease of Cleaning and Maintenance

Honey is a food product, making hygiene paramount. A machine designed for easy cleaning and maintenance reduces downtime between batches and prevents the risk of contamination. Look for stainless steel construction and easily accessible parts.

Specialized Features for Quality

Some machines offer features designed to protect honey's quality. For example, a double-layer insulated barrel helps maintain a consistent temperature, preserving the concentration and purity of the honey during the packaging process.

Understanding the Trade-offs

Choosing a machine involves balancing competing priorities. Being aware of these trade-offs will help you make a more informed decision.

Initial Cost vs. Total Cost of Ownership

The initial purchase price is only part of the equation. A cheaper machine might have higher long-term costs due to lower efficiency, more frequent maintenance, or higher product waste from inaccurate fills. Evaluate the total cost of ownership over the machine's lifespan.

Automation vs. Flexibility

Fully automated lines are incredibly efficient but can be rigid. They are optimized for high-volume production of a single container type. Semi-automatic systems often offer greater flexibility to switch between different packaging formats quickly.

The Hidden Cost of Poor Support

Consider the availability of technical support and spare parts. A machine that is down for days or weeks waiting for service or a replacement part can be far more costly than any initial savings.

Making the Right Choice for Your Goal

Your final decision should be guided by your primary business objective.

- If your primary focus is a small-batch, artisan product line: Prioritize a versatile and easy-to-clean semi-automatic machine that can handle various jar sizes with high precision.

- If your primary focus is scaling a growing business: Look for a modular, semi-automatic system that can be upgraded or a versatile entry-level automatic machine to future-proof your investment.

- If your primary focus is high-volume commercial production: Invest in a dedicated, high-speed, fully automated line designed for maximum efficiency, reliability, and minimal downtime.

Ultimately, selecting the right honey packaging machine is an investment in your brand's consistency, efficiency, and future growth.

Summary Table:

| Factor | Key Consideration | Impact |

|---|---|---|

| Production Scale | Semi-Automatic vs. Fully Automatic | Labor cost, throughput, investment level |

| Honey Viscosity | Piston filler vs. standard pump | Fill accuracy, consistency, product quality |

| Container Type | Jars/Bottles vs. Pouches | Nozzle type, drip prevention, sealing |

| Machine Features | Precision, ease of cleaning, insulation | Product waste, hygiene, honey quality preservation |

| Total Cost | Initial price vs. long-term ownership | ROI, maintenance, operational efficiency |

Ready to optimize your honey packaging process? At HONESTBEE, we specialize in supplying high-performance beekeeping supplies and equipment to commercial apiaries and distributors. Whether you need a semi-automatic machine for artisan batches or a fully automated line for large-scale production, our solutions are designed to enhance your efficiency, ensure consistent quality, and support your growth.

Contact us today to discuss your specific needs and discover how our wholesale-focused operations can deliver the perfect packaging solution for your business!

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Manual Honey Filling Machine Bottling Machine for Honey

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- How do industrial-grade honey filling machines ensure product quality? Precision & Hygiene for Large-Scale Output

- How do honey filling machines maintain product authenticity? Secure Your Honey's Integrity with Advanced Processing

- Why do organic honey and liquid foods need high-precision filling equipment for the EU? Key to Market Access

- What are the key advantages of semi-automatic filling machines? Optimize Your Honey Production Efficiency

- How do industrial honey filling machines protect monofloral honey value? Secure Premium Pricing with Precision

- What is the process of a liquid filling machine? A Guide to Choosing the Right Filling Method

- What are the benefits of using automatic filling machines? Enhance Quality & Efficiency in Commercial Honey Production

- What are the technical advantages of using automated honey-filling machines for high-value stingless bee honey?