In honey extraction, the filtration stage is the critical final step that purifies the product after it has been spun out of the comb. During this process, raw honey flows from the extractor through a series of filters or strainers designed to remove physical impurities like beeswax, propolis, and other hive debris, ensuring the final product is clean and ready for bottling.

The core purpose of filtration is to refine the honey's clarity, texture, and stability. It's a quality control measure that transforms raw, debris-filled honey from the extractor into the pure, smooth liquid consumers expect.

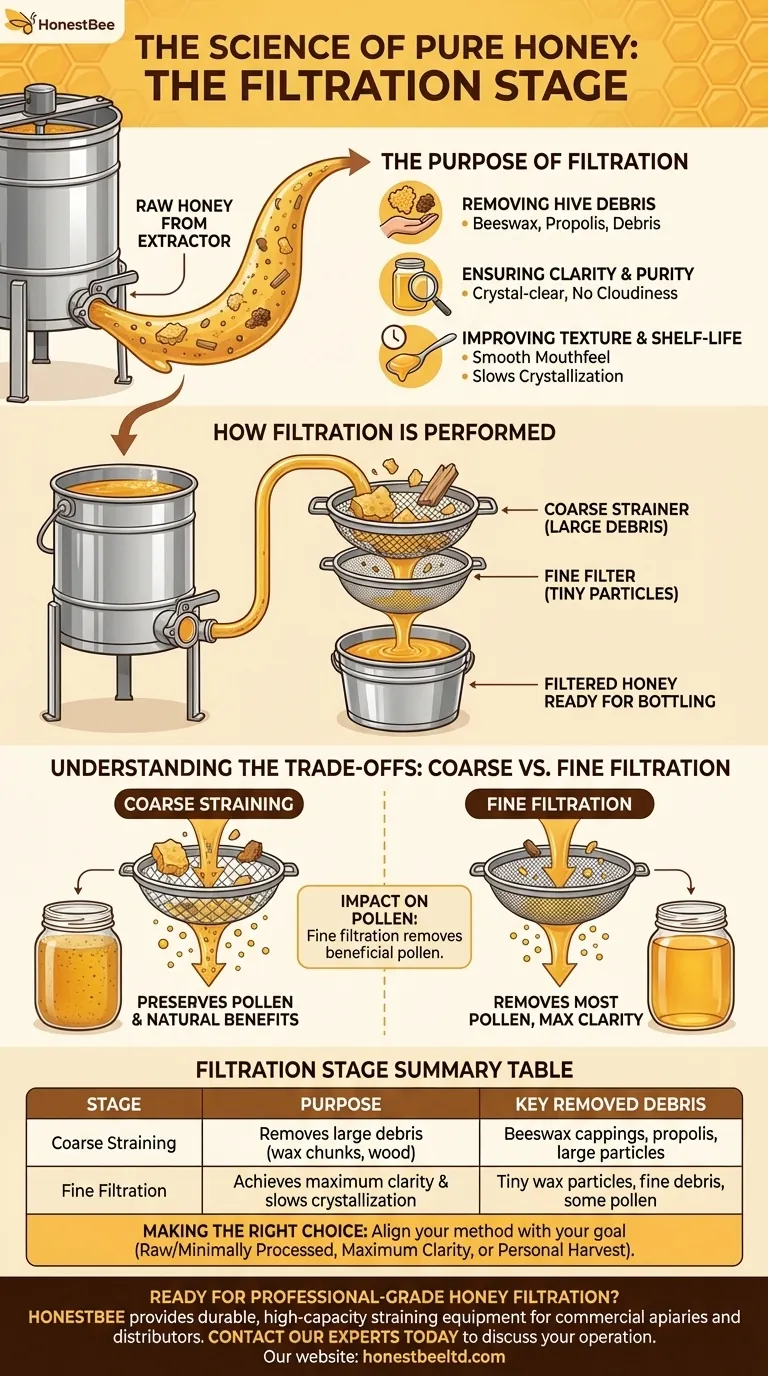

The Purpose of Honey Filtration

Filtration is more than just "cleaning" the honey. It's a deliberate step that defines the quality and characteristics of the final product.

Removing Hive Debris

After being spun in an extractor, raw honey contains various particles from the hive. Filtration is designed to remove these "impurities."

This debris commonly includes bits of wax cappings that were sliced off the comb, fragments of propolis (a resinous bee glue), wood splinters from the hive frames, and occasionally unfortunate bee parts.

Ensuring Clarity and Purity

Removing these suspended particles is essential for achieving the crystal-clear appearance that many people associate with high-quality honey.

Even small amounts of wax or other debris can make the honey appear cloudy, which can be undesirable for commercial sale or gifting.

Improving Texture and Shelf-Life

Small particles of wax can create a slightly grainy texture in the final product. Proper straining ensures a consistently smooth and pleasant mouthfeel.

Furthermore, these solid particles can act as nucleation sites, encouraging the honey to crystallize faster. Removing them can help prolong the honey's liquid state.

How Filtration is Performed

The process is typically simple and relies on gravity, though the specific tools can vary depending on the scale of the operation.

The Basic Setup

Honey is released from a valve on the extractor, often called a honey gate.

It flows directly into a bucket, but a filter or strainer is placed over the bucket's opening to catch the honey and screen out debris as it passes through.

Types of Filters

Beekeepers use a range of tools, from simple to complex. Common options include double-sieve stainless steel strainers, which have a coarse mesh on top to catch large debris and a finer mesh below.

For smaller batches, nylon straining bags or even multiple layers of cheesecloth can be used effectively. The size of the mesh determines how much is filtered out.

Understanding the Trade-offs

While filtration is necessary, the degree to which honey is filtered is a key consideration that impacts the final product.

Coarse Straining vs. Fine Filtration

A coarse strain uses a filter with larger openings. This method removes the big, noticeable debris like wax chunks and wood splinters.

A fine filtration uses a much smaller mesh. This process removes even tiny particles, resulting in exceptionally clear honey.

The Impact on Pollen

The most significant trade-off involves pollen. Coarse straining preserves the naturally occurring pollen grains in the honey, which many consumers value for their potential health benefits and for identifying the honey's floral origin.

Aggressive, fine filtration, especially methods used in large-scale commercial packing, can remove most of this beneficial pollen along with the impurities.

Making the Right Choice for Your Goal

The filtration method you choose should align directly with the type of honey you wish to produce.

- If your primary focus is "raw" or minimally processed honey: Use a single, coarse strainer to remove only the largest pieces of debris while preserving the natural pollen content.

- If your primary focus is maximum clarity for sale or competition: Use a double-sieve system, moving from a coarse to a fine mesh to produce a visually perfect, clear product.

- If your primary focus is a small, personal harvest: A simple, layered cheesecloth or a nylon paint strainer bag fitted over a bucket is a perfectly effective and economical solution.

Ultimately, proper filtration ensures your final product is a clean, beautiful, and honest representation of all the hard work that went into its creation.

Summary Table:

| Filtration Stage | Purpose | Key Removed Debris |

|---|---|---|

| Coarse Straining | Removes large debris (wax chunks, wood) | Beeswax cappings, propolis, large particles |

| Fine Filtration | Achieves maximum clarity & slows crystallization | Tiny wax particles, fine debris, some pollen |

Ready to achieve professional-grade honey filtration?

As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the durable, high-capacity straining equipment you need for a flawless product. Our filters and strainers are built for efficiency and scale, helping you maintain quality and maximize your yield.

Contact our experts today to discuss the right filtration solution for your operation.

Visual Guide

Related Products

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

- Premium Diamond-Faceted Glass Honey Dispenser

People Also Ask

- Why is stainless steel preferred for honey strainers? Ensure Purity and Durability for Your Honey

- What filter size for honey? A Beekeeper's Guide to Straining for Clarity and Quality

- What role does a honey filter play in ensuring purity? Achieve Clean, Market-Ready Honey

- What is the primary function of a high-mesh stainless steel sieve in honey processing? Ensure Purity and Clarity

- What is the importance of high-mesh nylon filtering cloth in honey processing? Ensure Purity & Retain Natural Quality

- Why is an 80-micron precision filter typically used for honey? Ensure International Purity & Compliance

- What is the best material for straining honey? Achieve Pure, High-Quality Honey with the Right Materials

- What role does the Chalna iron sieve play in the post-processing of raw honey? Enhancing Purity and Natural Quality