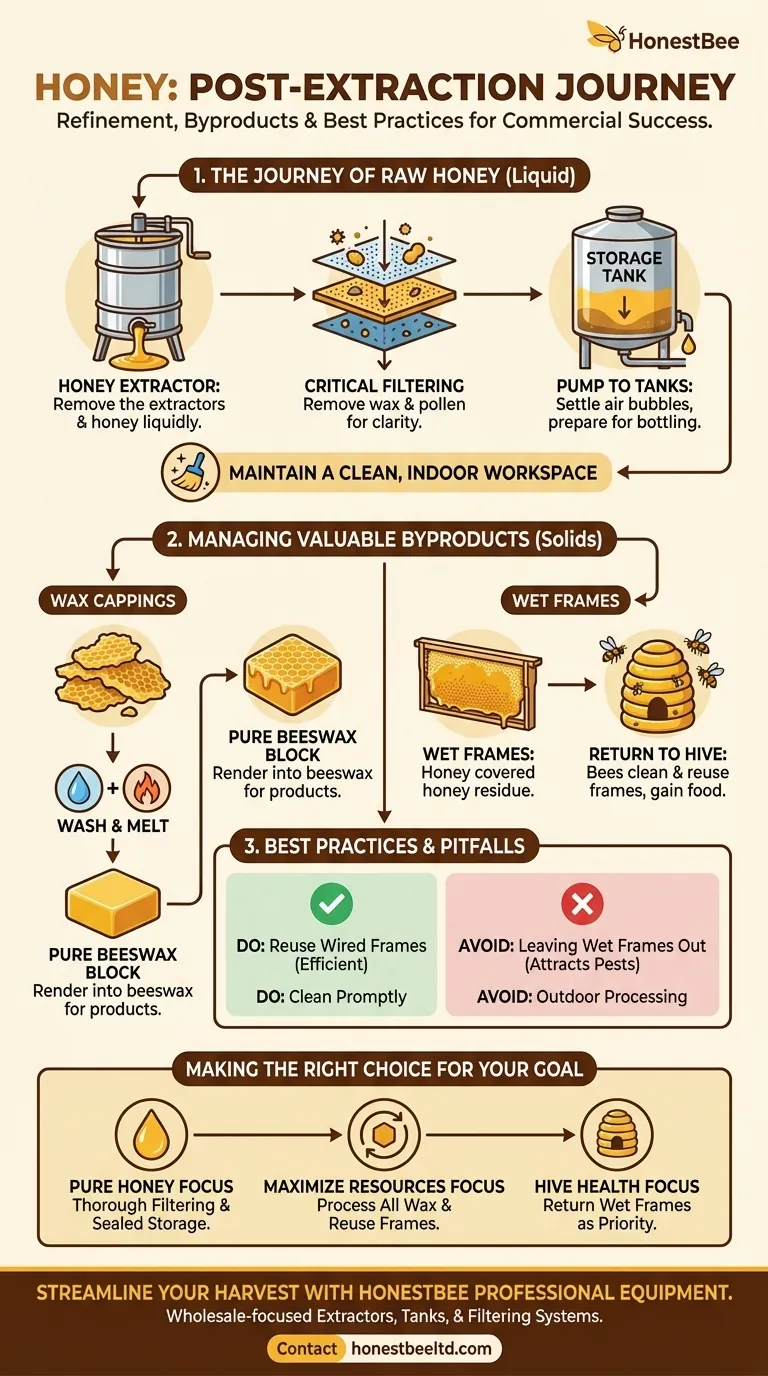

Once extracted from the comb, the raw honey begins a critical journey of refinement and storage. Immediately after leaving the extractor, the honey is strained or filtered to remove solid particles like beeswax and pollen, and then it is typically moved into a large storage tank to settle before being bottled or packed.

The work is not over once the honey is extracted. A successful harvest depends on a systematic post-extraction process that properly handles the honey, preserves valuable byproducts like wax, and prepares equipment for reuse.

The Journey of Raw Honey: From Extractor to Storage

The immediate goal after extraction is to prepare the liquid honey for consumption or long-term storage. This involves cleaning the honey and placing it in a secure environment.

The Critical Filtering Step

Raw honey straight from the extractor contains small bits of wax, propolis, and other hive debris.

Filtering is essential for producing the clear, clean honey consumers expect. This is typically done by passing the honey through a filter cloth or a series of screens.

Pumping to Storage Tanks

After initial filtering, the honey is often pumped into a food-grade holding tank.

This allows the honey to rest and settle, letting fine air bubbles rise to the surface. The tank keeps the honey in a single, secure location until it is ready for the final packing and bottling stage.

Maintaining a Clean Workspace

The entire process must occur indoors in a clean, food-safe area.

Extracting honey is an inherently sticky process, so protecting all surfaces is crucial. Attempting this outdoors is strongly discouraged, as the smell of fresh honey will quickly attract bees from your own and neighboring hives.

Managing the Valuable Byproducts

The extraction process leaves behind more than just honey. Beeswax cappings and the "wet" frames are valuable resources that should not be discarded.

Processing Wax Cappings

The wax cappings sliced off the frames before extraction are rich with honey and are a source of pure beeswax.

These cappings should be washed in water to remove the residual honey. The cleaned wax can then be melted, strained through cheesecloth to remove impurities, and poured into molds to form solid blocks of beeswax.

Uses for Rendered Beeswax

This rendered beeswax is a highly sought-after product.

It can be used to create a variety of items, including candles, lip balms, and soaps. Beekeepers can also use it to make new wax foundations for their hive frames.

Dealing with "Wet" Frames

After extraction, the frames still have a thin coating of honey, making them "wet."

The best practice for hobbyists is to place these wet frames back into the hive. The bees will efficiently clean every last drop of honey, which provides them with a valuable food resource.

Common Pitfalls to Avoid

A methodical approach to post-extraction cleanup prevents future problems and ensures you retain the maximum value from your harvest.

Preventing Pests

Leaving wet frames out in the open is a major mistake.

The residual honey will quickly attract pests like ants and wasps, creating a nuisance and a potential threat to your colonies. Promptly returning them to a hive is the cleanest solution.

Protecting Your Equipment

Using a honey extractor is the preferred method for a reason.

While the crush-and-strain method works, a centrifugal extractor keeps the comb within the frame intact. This means wired frames can be reused immediately, saving both the beekeeper and the bees significant time and energy.

Making the Right Choice for Your Goal

Your post-extraction priorities will determine your workflow. A clean and methodical process ensures that no part of the harvest goes to waste.

- If your primary focus is pure honey: Your goal is immediate and thorough filtering followed by transfer to a sealed, food-grade storage container.

- If your primary focus is maximizing resources: Meticulously collect and process every bit of wax cappings and ensure the wet frames are cleaned by the bees for reuse.

- If your primary focus is hive health: The top priority after bottling your honey is returning the wet frames to the colony to provide supplemental food and reduce waste.

Ultimately, a systematic approach transforms a messy job into an efficient process that benefits you and your bees.

Summary Table:

| Post-Extraction Step | Key Action | Purpose |

|---|---|---|

| Filtering | Strain honey through screens/cloth. | Remove wax, propolis, and debris for clarity. |

| Storage | Pump honey into food-grade settling tanks. | Let air bubbles rise; prepare for bottling. |

| Wax Cappings | Wash, melt, and strain wax. | Produce pure beeswax for products or foundations. |

| Wet Frames | Return frames to the hive. | Let bees clean them for reuse and gain a food source. |

Streamline your honey harvest with professional-grade equipment from HONESTBEE.

For commercial apiaries and beekeeping equipment distributors, our wholesale-focused operations supply the durable, high-capacity extractors, storage tanks, and filtering systems you need to maximize efficiency and product quality. Let us help you build a seamless post-extraction workflow.

Contact our team today to discuss your equipment needs and wholesale pricing.

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- How does specialized harvesting equipment influence the moisture content of honey? Optimize Quality and Stability

- What is the importance of separating honey from wax? Master Product Purity & Processing Efficiency

- How does specialized honey processing equipment improve quality? Elevate Purity & Market Value of Your Harvest

- What do VFFS and HFFS stand for in packaging machines? Choose the Right System for Your Product.

- What is the importance of automated honey filling and processing machinery? Drive Quality and Scale in Your Apiary

- Why is a pH meter recommended for honey acidity titration? Ensure Precision in Honey Quality Analysis

- How does deep-processing equipment contribute to the development of honey-themed cultural merchandise? Scale Your Brand

- What are the basic steps for extracting honey from frames? Master the Art of Efficient Beekeeping Extraction