Automatic Temperature Compensation (ATC) is a critical feature in a honey refractometer that automatically corrects the moisture reading to account for variations in the sample's temperature. This ensures you get an accurate measurement without needing to manually warm or cool the honey to a specific calibration temperature, providing reliable results directly from the hive or in your processing facility.

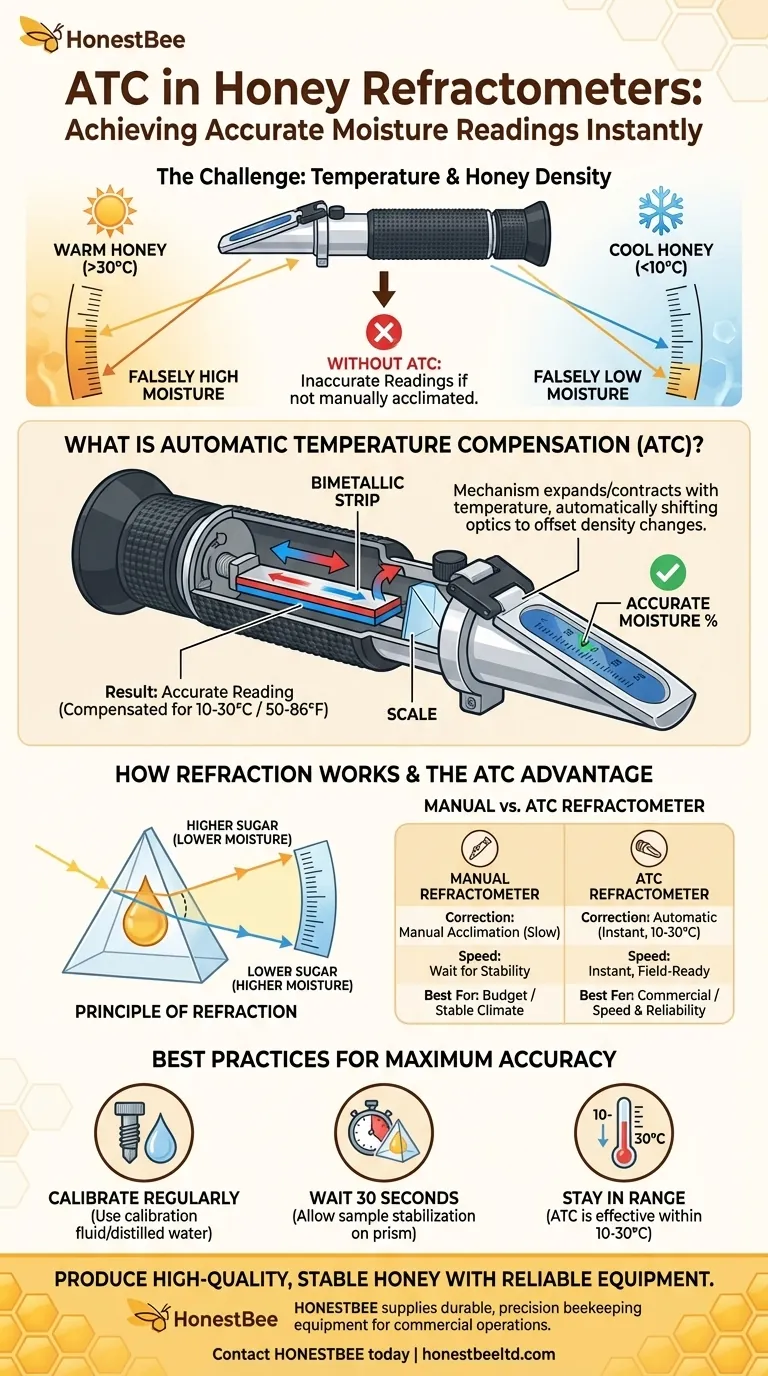

Temperature directly impacts the density and refractive index of honey. Without correction, a warm honey sample will appear to have a higher moisture content than it actually does, and a cool sample will appear drier. ATC is the internal mechanism that neutralizes this variable, making it the single most important feature for achieving fast and accurate readings.

How a Refractometer Measures Honey Moisture

The Principle of Refraction

A refractometer operates by measuring how light bends, or refracts, as it passes through a thin layer of honey.

The core of the device is a prism and a measurement scale. The concentration of dissolved solids in the honey—primarily sugars—determines its refractive index.

From Refraction to Moisture Content

Higher sugar concentration causes light to bend more, while lower sugar concentration (and thus higher moisture) causes it to bend less.

The refractometer is calibrated to correlate this angle of refraction directly to a moisture content percentage. You see this as a sharp line where the light and dark fields meet on the internal scale.

The Critical Impact of Temperature

Why Temperature Changes the Reading

The density of any liquid, including honey, changes with temperature. When honey is warm, it becomes less dense, and when it is cool, it becomes denser.

This change in density alters its refractive index. A warmer sample will bend light differently than a cooler sample of the exact same honey, leading to a false reading if not corrected.

The Problem with Manual Refractometers

On a refractometer without ATC, accuracy depends on the honey sample and the instrument being at the same ambient temperature, typically 20°C (68°F).

If you test cool honey on a warm day, the reading will be inaccurate. You must wait for the honey sample to acclimate to room temperature, which is often impractical in the field.

How ATC Solves the Problem

A refractometer with ATC has a built-in bimetallic strip that expands or contracts with temperature changes.

This strip is connected to the optics, physically shifting the scale or prism to offset the effect of temperature on the reading. It provides an accurate, compensated reading instantly, usually within a range of 10–30°C (50–86°F).

Understanding the Trade-offs and Best Practices

The Limits of ATC

ATC is not magic. It functions accurately only within a specified temperature range. If you test honey that is extremely hot or cold (outside the 50-86°F range), the compensation may not be sufficient, and the reading could still be incorrect.

The Importance of Calibration

ATC corrects for temperature, not for instrument error. You must still calibrate your refractometer regularly to ensure its fundamental accuracy.

Most units come with a calibration liquid or require distilled water. Verifying the reading against this known standard and adjusting the calibration screw if needed is essential for trustworthy measurements.

Best Practice for All Devices

For maximum accuracy, allow a drop of honey to sit on the prism for about 30 seconds before taking a reading. This allows the sample's temperature to stabilize with the temperature of the prism, giving the ATC mechanism time to work perfectly.

Making the Right Choice for Your Goal

Achieving an accurate moisture reading is non-negotiable for producing high-quality, stable honey. The right tool depends on your workflow and environment.

- If your primary focus is speed and efficiency: Choose a refractometer with ATC to get reliable readings instantly in the field or honey house without waiting for temperatures to equalize.

- If your primary focus is budget and you work in a stable climate: A manual refractometer is a viable option, but you must be disciplined about letting every sample acclimate to room temperature before testing.

- Regardless of your device: Always calibrate your refractometer before a session of use to guarantee your readings are based on a true and accurate standard.

Understanding how temperature affects your measurement empowers you to trust the data you collect and produce the best possible honey.

Summary Table:

| Feature | Manual Refractometer | ATC Refractometer |

|---|---|---|

| Temperature Correction | Requires manual sample acclimation | Automatic, within 10-30°C (50-86°F) range |

| Speed of Reading | Slow (must wait for temperature stability) | Instant, ideal for field use |

| Best For | Budget-conscious users in stable climates | Commercial apiaries needing speed and reliability |

| Calibration Required? | Yes, regularly with calibration fluid | Yes, regularly to ensure fundamental accuracy |

Produce High-Quality, Stable Honey with Reliable Equipment

For commercial apiaries and beekeeping equipment distributors, accurate moisture measurement is critical for honey quality and profitability. An ATC refractometer eliminates the variable of temperature, providing the fast, reliable data you need directly from the hive.

HONESTBEE supplies the durable, precision beekeeping supplies and equipment that commercial operations depend on. Our wholesale-focused operations ensure you get the right tools for efficient, large-scale honey production.

Contact HONESTBEE today to discuss your equipment needs and ensure every batch of honey meets your quality standards.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- Digital Honey Refractometer for Precision Measurement of Optimal Honey Quality

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- Why is an industrial-grade refractometer used to measure honey moisture? Ensure Stability and Prevent Fermentation

- What is the primary function of a desktop refractometer? Ensure Honey Quality and Prevent Fermentation

- What role does a high-precision refractometer play in honey moisture analysis? Ensure Honey Quality & Stability

- Why is a high-precision refractometer considered essential for honey quality? Master Moisture Control for Stability

- What is the function of a honey refractometer in beekeeping? Ensure Harvest Quality and Prevent Fermentation