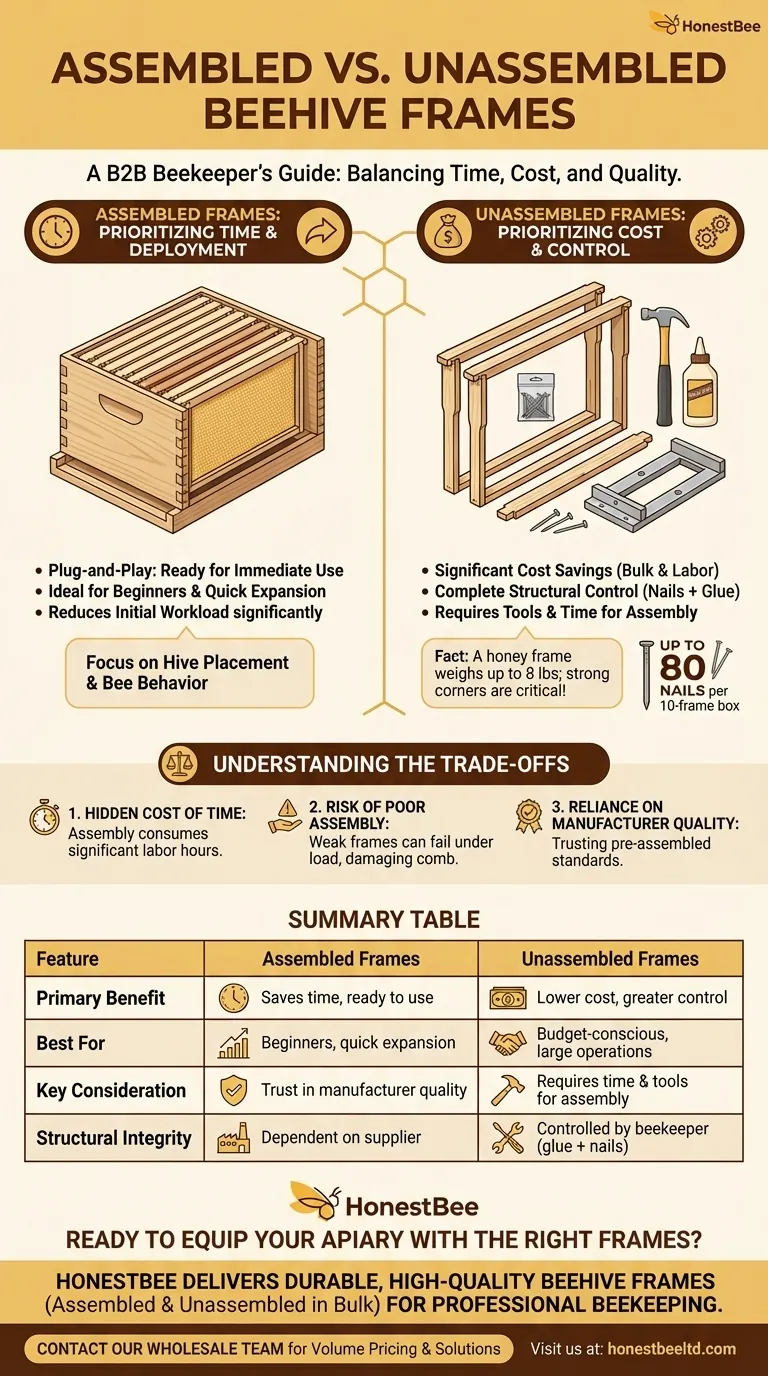

At its core, the difference is simple: assembled beehive frames are ready to be placed directly into your hive, while unassembled frames arrive as a kit of wooden parts that you must build yourself. This choice directly impacts your time, budget, and the structural integrity of your hive's most critical components.

The decision between assembled and unassembled frames is not just about convenience; it's a fundamental trade-off between investing your time versus your money. Your choice reflects your priorities as a beekeeper.

The Case for Assembled Frames: Prioritizing Time

Immediate Deployment

Assembled frames are the "plug-and-play" option for beekeeping. They arrive ready for you to install foundation and place them directly into your hive boxes.

This is especially valuable for beginners who are already navigating a steep learning curve or for any beekeeper who needs to expand their operation quickly.

Reducing Initial Workload

A new beekeeping setup involves many tasks. Using assembled frames removes a significant and time-consuming job from your initial checklist, allowing you to focus on hive placement, bee installation, and learning bee behavior.

The Case for Unassembled Frames: Prioritizing Cost and Control

Significant Cost Savings

The primary driver for choosing unassembled frames is a lower price point. By taking on the labor of assembly yourself, you can realize substantial savings, especially when setting up multiple hives.

The Assembly Process

Building the frames yourself involves fitting the four wooden pieces together and securing each corner. This typically requires a hammer, nails, and a frame jig or square to ensure proper alignment.

Most beekeepers use one or two nails per corner, meaning a single 10-frame box requires nailing up to 80 nails. Many experienced keepers also add wood glue to the joints for superior rigidity.

Controlling Structural Integrity

When you build your own frames, you have complete control over the quality. You can ensure every corner is perfectly square and securely fastened with both nails and glue.

This is not a trivial detail. A frame full of honey can weigh up to eight pounds, and a poorly constructed frame can sag or break under the load, creating a major problem inside your hive.

Understanding the Trade-offs

The Hidden Cost of Time

While unassembled frames cost less money, they demand a significant investment of time. Assembling frames for several hive bodies can easily consume an entire afternoon or evening. You must weigh the value of your time against the monetary savings.

The Risk of Poor Assembly

The cost savings of unassembled frames are lost if they are built incorrectly. Rushed or misaligned assembly leads to weak frames that can fail when you need them most—during a honey harvest. This can damage comb and make extraction difficult.

Reliance on Manufacturer Quality

With assembled frames, you are trusting the manufacturer's quality control. While usually reliable, you may occasionally find frames that are not perfectly square or securely nailed, which can be a frustrating discovery when you're in the middle of a hive inspection.

Making the Right Choice for Your Operation

Choosing the right frame type is about aligning the product with your personal beekeeping goals.

- If your primary focus is simplicity and saving time: Choose assembled frames to get your hives operational as quickly and easily as possible.

- If your primary focus is minimizing cost and maximizing quality control: Choose unassembled frames and invest the time to build them with glue and nails for maximum durability.

- If you are scaling a larger operation: Evaluate the trade-off between your labor costs (or personal time) and the bulk discount savings on unassembled components.

Ultimately, your choice of frame is one of the first decisions that defines your personal approach to beekeeping.

Summary Table:

| Feature | Assembled Frames | Unassembled Frames |

|---|---|---|

| Primary Benefit | Saves time, ready to use | Lower cost, greater control |

| Best For | Beginners, quick expansion | Budget-conscious beekeepers, large-scale operations |

| Key Consideration | Trust in manufacturer quality | Requires time and tools for assembly |

| Structural Integrity | Dependent on supplier | Controlled by the beekeeper (glue + nails recommended) |

Ready to equip your apiary with the right frames? Whether you're a commercial beekeeper managing hundreds of hives or a distributor supplying the industry, HONESTBEE delivers the durable, high-quality beehive frames you need. We offer both assembled and unassembled options in bulk, designed for the rigors of professional beekeeping.

Contact our wholesale team today to discuss volume pricing and find the perfect frame solution to maximize the efficiency and productivity of your operation.

Visual Guide

Related Products

- Mini Desktop Bee Hive Frame Forming Making Machine

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- Frame Eyelets Assembly Machine Bee Frame Eyelets Fitting Machine Eyelets Machine

- HONESTBEE Professional Bee Frame Machine for Side Bar Shaping

- Automatic Pneumatic Bee Frame Machine for Eyelet Insertion

People Also Ask

- Why is modern hive construction a highly sought-after skill? Master the Art of Cost-Effective Apiary Expansion

- How does the Beehive Frame Making Machine allow for customizable frame production? Precision Woodworking for Apiaries

- What is the purpose of a small desktop bee frame forming machine? Automate Frame Assembly for Beekeepers

- What role does standardized wooden beehive manufacturing machinery play? Scale Your Apiary with Industrial Precision

- How should the working area be prepared before making Langstroth beehive frames? Optimize Your Frame Assembly Workflow