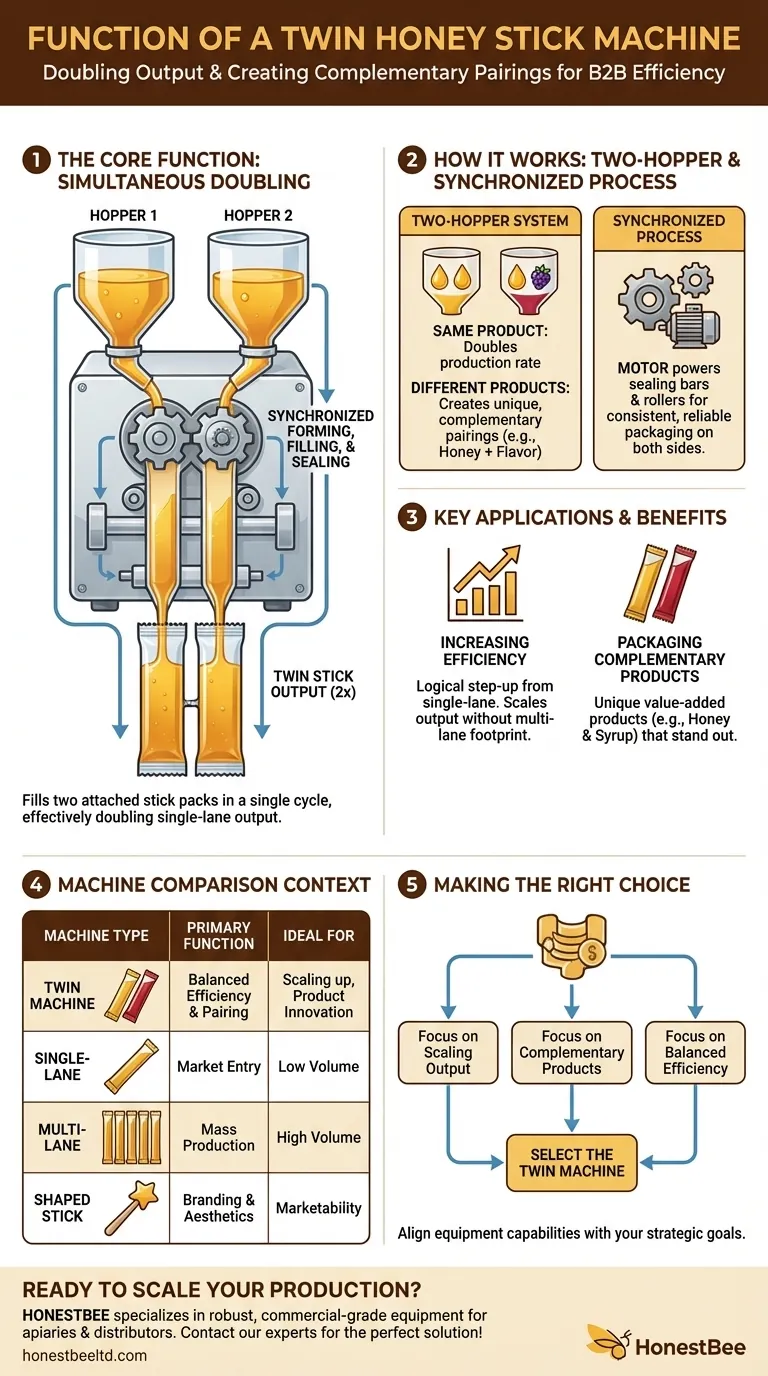

At its core, a twin honey stick machine is a specialized piece of packaging equipment designed to fill two attached stick packs at the same time. Using two separate product hoppers, it simultaneously forms, fills, and seals two sticks, effectively doubling the output of a single-lane machine in a single cycle.

The primary function of a twin honey stick machine is to increase production efficiency. It achieves this by either creating two identical honey sticks at once or by packaging complementary products, like honey and a separate flavoring, side-by-side.

The Core Function: Doubling Output Simultaneously

A twin honey stick machine operates on a simple but powerful principle. It's built to handle two packaging streams in parallel, which provides distinct operational advantages.

The Two-Hopper System

The machine is equipped with two separate product hoppers. This is a critical design feature.

These hoppers can be filled with the same product, such as honey, to simply double the production rate of standard honey sticks.

Alternatively, they can hold two different products. This allows for the creation of innovative, complementary product pairings in one convenient package.

The Synchronized Process

The machine's mechanics ensure that the forming, filling, and sealing processes are perfectly synchronized for both stick packs.

A motor provides the mechanical energy to power the sealing bars and film rollers, ensuring a consistent and reliable packaging process for both sides.

The Final Product

The output is a "twin stick"—two individual stick packs that are attached to each other. This format is ideal for retail sale as a single unit or for inclusion in larger product kits.

Why Choose a Twin Machine? Key Applications

While a standard machine makes one stick at a time, and a multi-lane machine makes many, the twin machine occupies a specific niche focused on efficiency and product pairing.

Increasing Production Efficiency

For businesses scaling up from a single-lane operation, a twin machine is a logical next step. It doubles output without the significantly larger footprint and investment required for a full multi-lane system.

Packaging Complementary Products

This is the most unique application. A company could fill one side with honey and the other with a fruit syrup, chocolate sauce, or herbal infusion. This creates a value-added product that stands out on the shelf.

How a Twin Machine Compares to Other Models

Understanding where the twin machine fits requires comparing it to other common types of honey stick packaging equipment. Its function is best understood in context.

vs. Standard Single-Lane Machines

A twin machine is a direct upgrade in terms of throughput. It is designed for businesses whose demand has outgrown the capacity of a basic, single-stream packaging line.

vs. Multi-Lane Machines

Multi-lane machines are built for mass production, with some models having up to 20 lanes producing over a thousand sticks per minute. A twin machine is essentially a two-lane machine, making it a stepping stone toward high-volume industrial production.

vs. Shaped Stick Machines

Shaped stick machines prioritize marketability and branding over raw speed. They create unique shapes and seals to attract consumers, especially children. The goal is aesthetic appeal, whereas the twin machine's primary function is enhancing production volume and enabling product pairing.

Making the Right Choice for Your Production Line

Selecting the correct machine is entirely dependent on your business goals, production scale, and product strategy.

- If your primary focus is entering the market or creating unique, branded shapes: A standard single-lane or a shaped stick machine is the most direct and cost-effective solution.

- If your primary focus is increasing output or packaging paired products: The twin honey stick machine is specifically designed for this purpose, offering a balance of efficiency and versatility.

- If your primary focus is maximum throughput for large-scale distribution: A multi-lane machine is the necessary investment to meet high-volume demands.

Ultimately, understanding the specific function of each machine allows you to align your equipment capabilities with your strategic goals.

Summary Table:

| Function | Key Benefit | Ideal For |

|---|---|---|

| Doubles Output | Increases production efficiency by packaging two identical sticks at once. | Scaling up from a single-lane machine. |

| Packages Paired Products | Creates innovative products by filling two sticks with different items (e.g., honey & syrup). | Developing value-added, complementary products. |

| Synchronized Operation | Two hoppers and a single motor ensure consistent, reliable filling and sealing for both sticks. | Businesses needing reliable, balanced production. |

Ready to scale your honey stick production or create innovative product pairings?

As HONESTBEE, we specialize in supplying robust, commercial-grade packaging equipment to commercial apiaries and beekeeping equipment distributors. Our twin honey stick machines are engineered for durability and high performance in wholesale-focused operations, helping you meet growing demand efficiently.

Contact our experts today to find the perfect packaging solution for your business goals!

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Manual Honey Filling Machine Bottling Machine for Honey

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- How do industrial honey-filling machines boost apitourism value? Transform Your Production into a Premium Experience

- Why has the small bag honey packaging machine been favored by manufacturers? Unlock Efficiency & Quality

- What is the purpose of a Weighing Filling Machine? Ensure Precision and Profitability

- What is the purpose of the caster wheels in a honey stick machine? Enable Flexibility and Stability

- Why are high-precision honey filling machines and labeling equipment necessary for the commercialization of stingless bee honey?

- Why are automated honey filling machines essential? Transform Your Honey Production for Global Commercial Success

- How do industrial honey filling machines improve product value? Scale Your Branding and Quality Control

- How does the use of professional honey-filling machinery improve the commercial value of stingless bee honey?