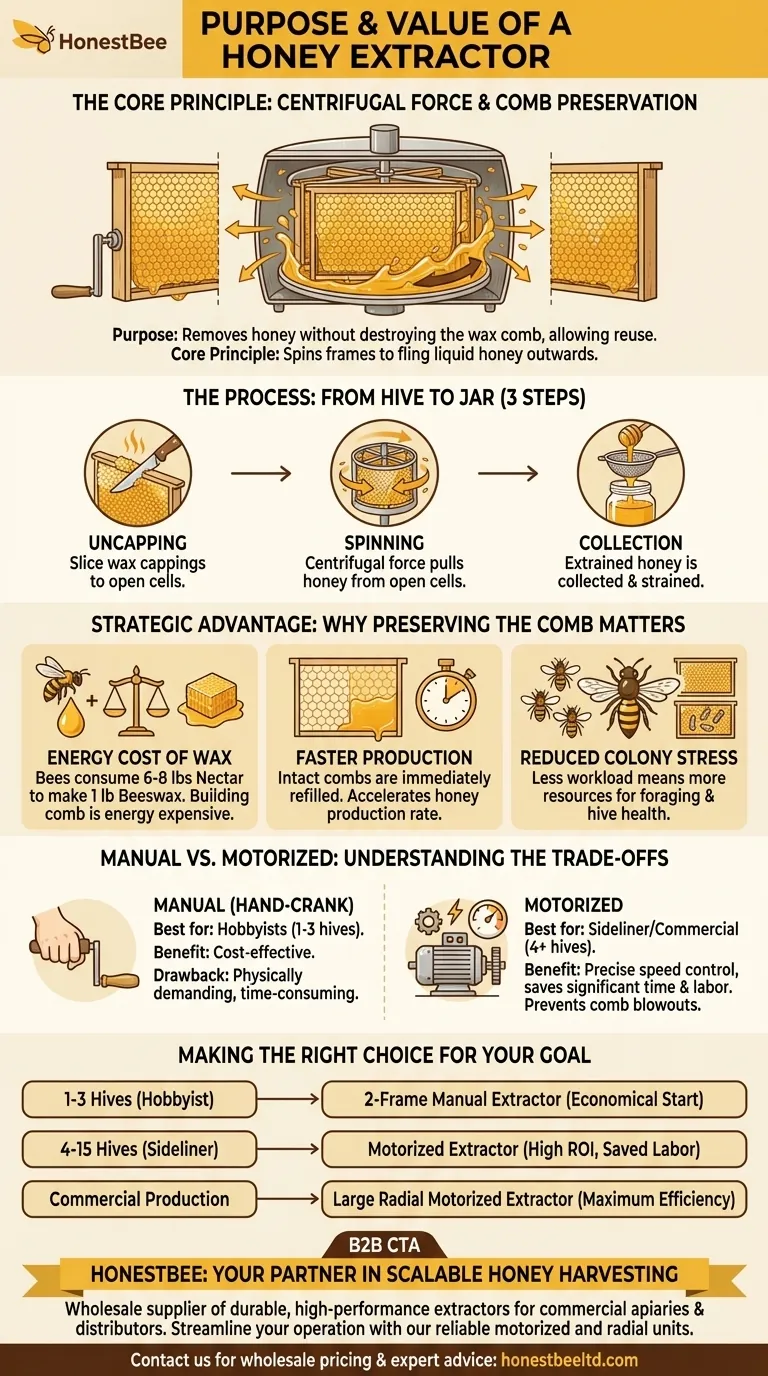

At its core, a honey extractor is a machine that uses centrifugal force to remove honey from honeycomb frames. Its primary purpose is to get the honey out of the comb without destroying the delicate wax structure, allowing the bees to reuse it.

The true value of a honey extractor isn't just in harvesting honey, but in promoting a more sustainable and productive apiary. By preserving the honeycomb, you save your bees an immense amount of energy, allowing them to focus on making more honey.

The Core Principle: Harnessing Centrifugal Force

A honey extractor works much like a salad spinner. By spinning the frames at high speed, it generates a force that flings the liquid honey outwards against the wall of the extractor drum, leaving the wax comb intact.

Step 1: Uncapping the Combs

Before extraction, the beekeeper must slice off the thin wax cappings that bees build to seal the honey in each cell.

Step 2: The Spinning Process

The uncapped frames are placed inside the extractor's basket. As the basket spins, the outward force pulls the honey from the open cells.

Step 3: Collection and Straining

The extracted honey pools at the bottom of the drum. It can then be drained through a gate, typically through a series of strainers to remove any bits of wax before jarring.

The Strategic Advantage: Why Preserving the Comb Matters

The single most important benefit of using an extractor is the preservation of the drawn-out honeycomb. This provides a profound advantage for the honeybee colony.

The Energy Cost of Wax

Bees must consume a significant amount of nectar—estimates range from 6 to 8 pounds—just to produce 1 pound of beeswax. Building comb is an energetically expensive task.

Faster Honey Production

When you return empty, intact combs to the hive, the bees can immediately begin refilling them with nectar. This bypasses the entire comb-building process, dramatically accelerating the rate of honey production.

Reduced Colony Stress

By giving the bees a head start, you reduce the overall workload and stress on the colony. This allows them to dedicate more resources to foraging, raising brood, and maintaining hive health.

Understanding the Trade-offs: Manual vs. Motorized

The primary decision point for a beekeeper is choosing between a hand-cranked or a motorized unit. This choice directly impacts efficiency and cost.

Manual (Hand-Crank) Extractors

These are powered by human effort. They are an excellent, cost-effective choice for hobbyists with only a few hives. However, the process is physically demanding and time-consuming for larger operations.

Motorized Extractors

Powered by a motor, these units offer precise speed control and require minimal physical labor. They dramatically increase productivity and are essential for any beekeeper with more than a handful of hives. The ability to gradually increase speed prevents comb blowouts.

The Impact on Workflow

For beekeepers with multiple hives, a multi-frame motorized extractor is a game-changer. It transforms honey harvesting from a multi-day chore into an efficient, streamlined process.

Making the Right Choice for Your Goal

Selecting the right extractor depends entirely on the scale and ambition of your beekeeping operation.

- If your primary focus is hobbyist beekeeping (1-3 hives): A small, two-frame manual extractor is the most practical and economical starting point.

- If your primary focus is growing into a sideliner operation (4-15 hives): A motorized extractor will provide a significant return on investment through saved time and labor.

- If your primary focus is commercial production: A large, motorized radial extractor is a non-negotiable tool for achieving operational efficiency.

Ultimately, investing in an extractor is an investment in the long-term health and productivity of your bees.

Summary Table:

| Extractor Type | Best For | Key Benefit |

|---|---|---|

| Manual (Hand-Crank) | Hobbyists (1-3 hives) | Cost-effective, economical |

| Motorized | Sideliner/Commercial (4+ hives) | Saves time/labor, precise speed control |

| Radial (Commercial) | Large-scale operations | Maximum efficiency for high-volume harvesting |

Ready to streamline your honey harvest and boost your apiary's productivity?

As a leading wholesale supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the durable, high-performance extractors you need to scale your operation efficiently. Our motorized and radial extractors are built for reliability, saving you valuable time and labor while preserving the health of your colonies.

Let's discuss the right extractor solution for your business goals. Contact our team today for wholesale pricing and expert advice.

Visual Guide

Related Products

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- How do honey collectors collect honey? A Step-by-Step Guide to Efficient Harvesting

- Why is cleaning a honey extractor important in beekeeping? Protect Your Honey Quality & Equipment

- What is the function of a honey extractor in honey processing? Boost Your Honey Yield & Bee Health

- What are the best storage conditions for a honey extractor? Protect Your Investment for Next Season

- What is an extractor in beekeeping? Unlock Sustainable Honey Harvesting