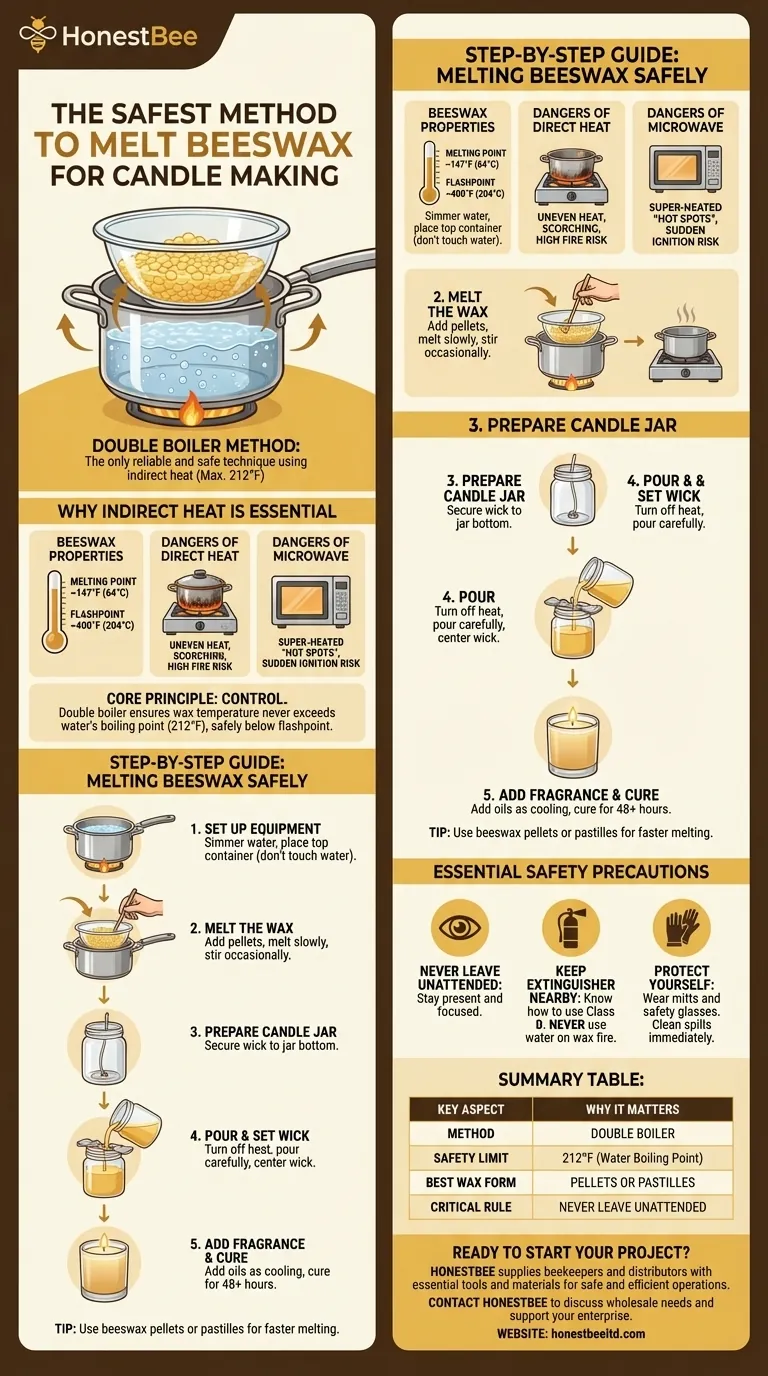

The safest and most reliable method to melt beeswax for candle making is the double boiler method. This technique uses gentle, indirect heat by placing a heat-resistant container of wax over a pot of simmering water. This approach ensures the wax melts slowly and evenly without ever reaching its dangerous flashpoint.

The core principle is control. Beeswax is flammable, and direct heat from a stove or microwave is difficult to regulate and can easily lead to a fire. The double boiler method is non-negotiable because it uses the temperature of boiling water (212°F) as a natural safety limit, keeping the wax far below its ignition point.

Why Indirect Heat is Essential

Beeswax is a natural and wonderful material for candles, but it must be handled with respect for its properties. Understanding why direct heat is so hazardous is the first step in safe candle making.

The Flammability of Beeswax

Beeswax has a relatively low melting point of around 147°F (64°C). However, its flashpoint—the temperature at which its vapors can ignite—is approximately 400°F (204°C). A direct flame or an electric burner can easily exceed this temperature, creating a significant fire risk.

The Dangers of Direct Heat and Microwaves

Placing beeswax in a pot directly on a stove is a common mistake. It creates intense, uneven heat at the bottom of the pot, which can easily scorch the wax and push it past its flashpoint before the rest of the wax has even melted.

Using a microwave is equally dangerous. Microwaves can create super-heated "hot spots" within the wax, leading to a sudden and unexpected ignition inside the appliance.

How a Double Boiler Provides Safety

The double boiler method works by using steam and simmering water to transfer heat. A pot filled with a few inches of water is heated, and a second, smaller heat-proof container holding the beeswax is placed on top.

The water heats the container gently and consistently. Because water boils at 212°F (100°C), the wax temperature can never exceed this point, keeping it safely below the 400°F flashpoint.

A Step-by-Step Guide to Melting Beeswax

This process is straightforward and ensures a safe, successful outcome. For faster melting, always opt for beeswax pellets or pastilles over large blocks.

1. Set Up Your Equipment

Fill a medium-sized pot with 1-2 inches of water and bring it to a gentle simmer over medium heat. Place a smaller, heat-resistant pouring pot or glass bowl securely on top. Ensure the bottom of the top container does not touch the water.

2. Melt the Wax

Add your beeswax pellets to the top container. If your recipe includes other ingredients like coconut oil, you can add them at this stage. Allow the wax to melt slowly, stirring occasionally with a bamboo skewer or heat-resistant spatula.

3. Prepare Your Candle Jar

While the wax is melting, prepare your candle container. Use a hot glue gun or a wick sticker to firmly attach the metal tab of your wick to the center of the jar's bottom.

4. Pour and Set the Wick

Once the wax is completely melted and clear, turn off the heat. Carefully remove the pouring pot using oven mitts. Let the wax cool for a moment before pouring it steadily into your prepared jar. Use a wick centering tool or two chopsticks to hold the wick straight as the wax begins to set.

5. Add Fragrance and Cure

If you are using essential oils for fragrance, add them now as the wax begins to cool. Stir gently to combine. Allow the candle to cure, completely undisturbed, for at least 48 hours to a week before its first burn.

Essential Safety Precautions

Following these rules is critical for preventing accidents. Candle making is a safe hobby only when you remain vigilant.

Never Leave Melting Wax Unattended

A wax fire can start in seconds. Always stay present and focused on the task from the moment you turn on the heat until you have finished pouring.

Keep a Fire Extinguisher Nearby

Have a Class B fire extinguisher accessible and know how to use it. Never use water to extinguish a wax fire, as it will cause the flaming wax to splatter and spread. Smother the flame with a metal lid instead.

Protect Yourself and Your Workspace

Hot wax can cause severe burns. Always wear protective gear like oven mitts and safety glasses. Clean up any drips or spills immediately to prevent slips or accidental contact.

Making the Right Choice for Your Goal

Your approach to candle making should always prioritize safety, regardless of your experience level.

- If your primary focus is safety and a high-quality candle: Always use the double boiler method. Its slow, controlled process is a feature, not a flaw, as it prevents scorching and eliminates fire risk.

- If you are a beekeeper processing raw cappings: The same safety principles apply. Use indirect heat to safely separate residual honey and render clean wax for candles or other projects.

- If you are creating a non-toxic home environment: Making your own beeswax candles is an excellent choice. This process gives you complete control over the purity of your ingredients, ensuring a clean burn without synthetic additives.

Mastering this simple, safe melting technique is the foundational step to creating beautiful and natural beeswax candles in your own home.

Summary Table:

| Key Aspect | Why It Matters |

|---|---|

| Method | Double Boiler |

| Safety Limit | 212°F (Water Boiling Point) |

| Best Wax Form | Pellets or Pastilles |

| Critical Rule | Never Leave Unattended |

Ready to Start Your Beekeeping or Candle Making Project?

For commercial apiaries and distributors, having a reliable supply of high-quality beeswax and equipment is the first step to success. HONESTBEE supplies beekeepers and beekeeping equipment distributors with the essential tools and materials needed for safe and efficient operations, from hive management to candle production.

We provide the quality supplies that help your business thrive.

Contact HONESTBEE today to discuss your wholesale needs and discover how we can support your beekeeping enterprise.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

People Also Ask

- Why is it important to heat honey slowly and evenly? Preserve Flavor, Nutrients & Value

- What is melter honey used for? A Low-Cost Ingredient for Bakers and Brewers

- What is the effect of heating on honey? Preserve Quality with Controlled Warming

- What is the water bath method for honey processing? A Gentle Technique for Quality Honey

- At what temperature does honey flow? Preserve Quality with the Perfect 95°F Sweet Spot