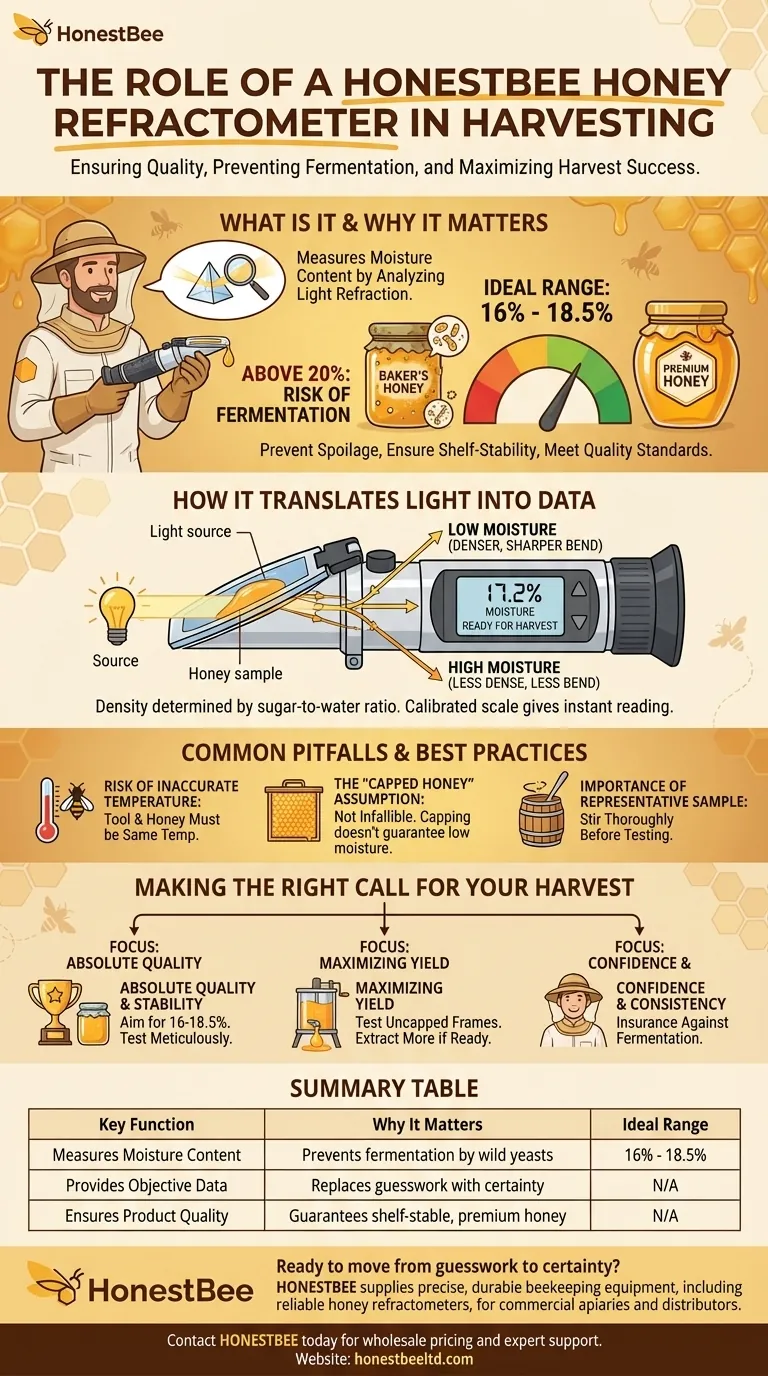

In short, a honey refractometer is a specialized tool that measures the moisture content of honey. By analyzing how light bends as it passes through a small honey sample, it tells a beekeeper the precise moment the honey is "cured" and ready for a successful harvest. This measurement is the single most important factor in preventing spoilage and ensuring a high-quality, shelf-stable product.

Harvesting honey is a race against fermentation. The refractometer is the definitive tool that ensures you win that race by providing objective data on your honey's stability, moving you from guesswork to certainty.

Why Moisture Content Defines Honey Quality

The difference between premium, shelf-stable honey and a spoiled, fermented batch comes down to one primary factor: water. A refractometer gives you the power to control for this variable.

The Ever-Present Threat of Fermentation

Honey naturally contains dormant wild yeasts. If the moisture content is too high—generally above 20%—these yeasts activate and begin to ferment the sugars in the honey.

This process ruins the honey's flavor, produces alcohol and carbon dioxide, and renders it unusable for most purposes. Fermented honey, sometimes called "baker's honey," is a costly and preventable failure.

Ensuring Long-Term Stability

The ideal moisture content for honey is between 16% and 18.5%. Within this range, the high sugar concentration creates an environment where yeast and other microbes cannot survive.

This is what gives honey its legendary shelf life. By verifying your honey is within this range, you guarantee its stability for long-term storage and sale.

Meeting Quality and Legal Standards

Many jurisdictions have legal requirements for honey sold to the public. For example, some standards mandate that honey must have a moisture content below 21%.

Using a refractometer is not just good practice; it is a key step in professional compliance, ensuring your product meets the established grade for "honey."

How a Refractometer Translates Light into Data

The device operates on a simple, reliable principle of physics. It doesn't use chemical analysis but rather the physical properties of the honey itself.

The Principle of Refraction

When light passes from the air into a different medium, like water or honey, it bends or "refracts." The denser the medium, the more the light bends.

A refractometer is designed to precisely measure this angle of refraction.

Sugar's Role in Bending Light

The density of honey is determined almost entirely by its sugar-to-water ratio. Honey with a high sugar concentration (and therefore low moisture) is denser.

Because it is denser, low-moisture honey will bend light more sharply than high-moisture, less-dense honey.

From Refractive Index to Moisture Percentage

The refractometer's internal scale, visible through the eyepiece, is calibrated specifically for honey.

It automatically translates the measured angle of refraction into a direct moisture percentage reading. This gives you an instant, actionable data point without any complex calculations.

Common Pitfalls and Best Practices

While simple to use, a refractometer's accuracy depends on correct procedure. Missteps can lead to poor decisions that undermine the very purpose of using the tool.

The Risk of Inaccurate Temperature

For an accurate reading, the refractometer and the honey sample must be at the same temperature. A warm tool and cold honey (or vice versa) will skew the results.

Always allow the tool and the honey to acclimate to the same ambient temperature before placing a drop on the prism.

The "Capped Honey" Assumption

Beekeepers have long used fully capped honeycomb as a visual cue that the honey is ready. While this is a good rule of thumb, it is not infallible.

Climate, humidity, and hive dynamics can result in capped honey that still has a high moisture content. Conversely, some uncapped honey may be perfectly ready. The refractometer provides the definitive answer that visual inspection cannot.

The Importance of a Representative Sample

A single drop of honey only represents that specific drop. If you are testing honey from a large container or extractor, stir it thoroughly first.

Moisture can stratify, with wetter honey rising to the top. Failure to mix the honey can give you a reading that doesn't represent the entire batch.

Making the Right Call for Your Harvest

Using a refractometer is about replacing assumptions with data. Your harvesting strategy can be tailored based on the objective information you gather.

- If your primary focus is absolute quality and stability: Aim for the ideal range of 16-18.5% and be meticulous about testing samples from different frames and supers before extracting.

- If your primary focus is maximizing yield: Use the refractometer to test uncapped frames. You may find some sections are ready for harvest, allowing you to extract more honey than if you relied on capping alone.

- If you are a hobbyist seeking confidence: The refractometer is your best insurance policy against the disappointment of fermented honey, ensuring your hard work results in a product you can be proud of.

Ultimately, this tool empowers you to make harvesting decisions based on evidence, not just tradition.

Summary Table:

| Key Function | Why It Matters | Ideal Range |

|---|---|---|

| Measures Moisture Content | Prevents fermentation by wild yeasts | 16% - 18.5% |

| Provides Objective Data | Replaces guesswork with certainty | N/A |

| Ensures Product Quality | Guarantees shelf-stable, premium honey | N/A |

Ready to move from guesswork to certainty in your harvest?

As a commercial apiary or beekeeping equipment distributor, the quality of your honey and the efficiency of your operation are paramount. HONESTBEE supplies the precise, durable beekeeping equipment you need to succeed.

We provide wholesale-focused solutions, including reliable honey refractometers, to help you prevent spoilage, meet quality standards, and maximize your yield. Let's discuss how our supplies can strengthen your business.

Contact HONESTBEE today for wholesale pricing and expert support.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- Digital Honey Refractometer for Precision Measurement of Optimal Honey Quality

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Portable Uncapping Tank Holder Uncapping Bench for Beekeeping

- Professional 3-Bar Frame Grip with Integrated Hive Tool

People Also Ask

- What should be considered regarding the measurement range of a honey refractometer? Ensure Peak Honey Quality

- Why is a laboratory benchtop refractometer essential for honey? Secure Stability & Quality

- What role does a high-precision refractometer play in honey moisture analysis? Ensure Honey Quality & Stability

- Why is a refractometer necessary for determining the moisture content and quality grade of honey? Ensure Market Success

- What is the principle and importance of using a refractometer for honey moisture? Ensure Quality & Prevent Fermentation