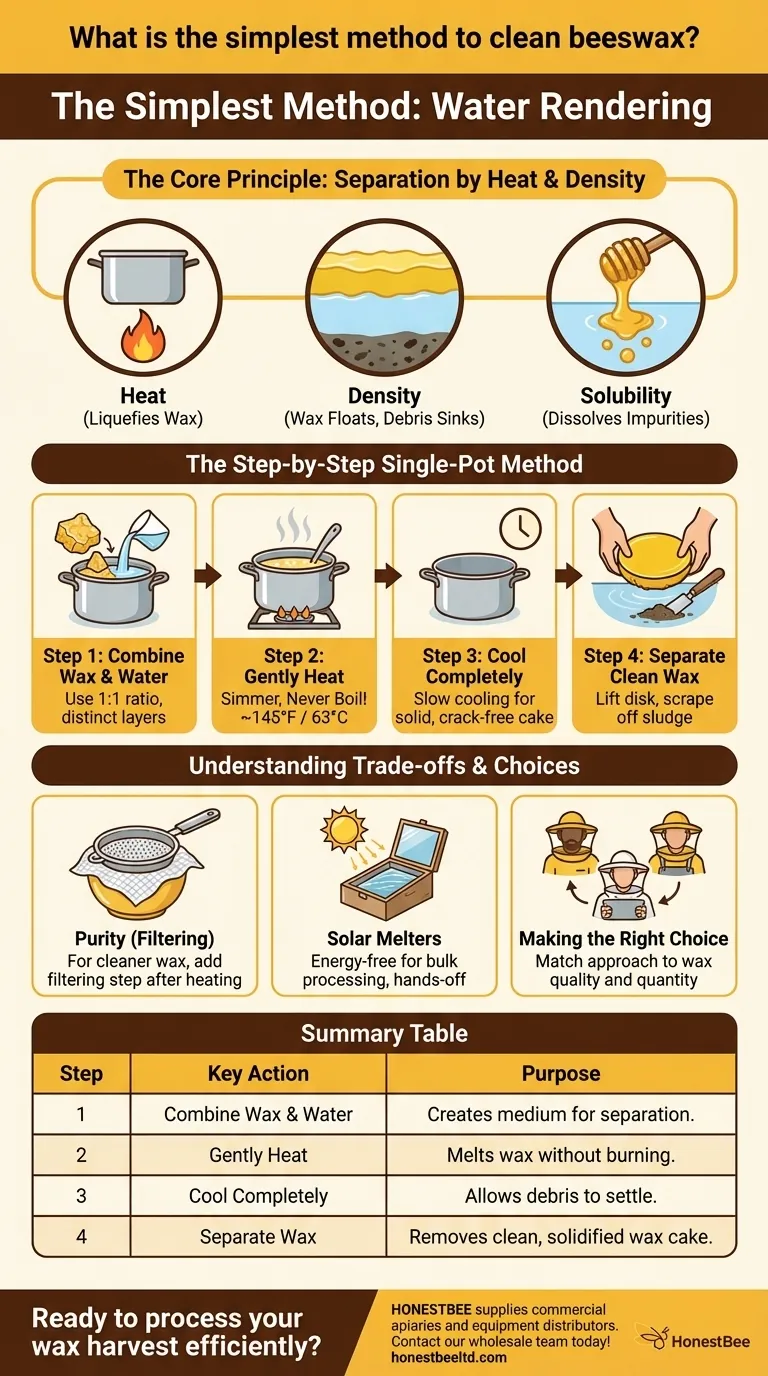

The simplest and most effective method for cleaning raw beeswax is water rendering. This process involves melting the wax in water, allowing the mixture to cool completely, and then separating the solidified, clean wax from the water and debris that have settled at the bottom.

The core principle is not simply melting, but using the different densities of wax, water, and debris. Hot water provides a medium for the lighter wax to float, heavier debris to sink, and water-soluble impurities like honey to dissolve away.

The Principle: Why Water Rendering Works

To clean beeswax effectively, you are performing a simple act of physical separation. Water is the ideal medium to facilitate this process for three key reasons.

The Role of Heat

Melting the wax is the essential first step. In its solid, raw form—as cappings, burr comb, or old honeycomb—impurities are trapped within the wax structure. Applying gentle heat liquefies the wax, releasing the debris.

Separation by Density

Once melted, the components naturally stratify. Beeswax is hydrophobic (repels water) and less dense than water, so it floats to the surface. Most impurities, such as dirt, propolis, and other hive debris, are heavier and will sink through the water to the bottom of the pot.

Removing Soluble Impurities

Raw wax often contains residual honey or other water-soluble elements. The hot water bath acts as a solvent, dissolving these impurities and holding them in the water layer, separate from the pure wax.

The Step-by-Step Single-Pot Method

This is the foundational technique suitable for nearly any quantity of raw wax. It requires only a dedicated pot (not used for food), water, and a heat source.

Step 1: Combine Wax and Water

Place your raw beeswax into a pot. Add enough water to ensure that once the wax melts, there will be a distinct layer of water underneath it. A 1:1 ratio by volume is a good starting point.

Step 2: Gently Heat the Mixture

Heat the pot over low to medium heat. Never boil the mixture. Overheating can darken the beeswax and is a fire hazard. The goal is to bring the water to a gentle simmer, which is more than enough to melt the wax (which melts around 145°F / 63°C).

Step 3: Cool Slowly and Completely

Once the wax is fully melted, turn off the heat and let the pot cool undisturbed. Slow cooling is critical for allowing the debris to fully settle and for forming a solid, crack-free cake of wax. Letting it sit overnight is ideal.

Step 4: Separate the Clean Wax

After the pot is completely cool, the beeswax will have solidified into a hard disk on top of the water. You can easily lift or pry this disk out. The bottom of the wax disk will have a layer of sludge and debris, which can be scraped off with a hive tool or knife.

Understanding the Trade-offs

While simple water rendering is highly effective, it's important to understand its limitations and when to modify the process.

The Purity of the First Pass

For wax that starts with a large amount of debris (like old, dark brood comb), a single rendering may not be enough. Some very fine particles can remain suspended, leaving a sludgy layer on the bottom of the final wax cake.

Improving Purity with Filtering

For a cleaner final product, you can add a filtering step. After the wax has melted in the water (Step 2), pour the entire hot mixture through a strainer lined with cheesecloth or a sturdy paper towel into a second cooling container (like a plastic bucket). This physically removes debris before the cooling and separation stage.

The Alternative: Solar Melters

For beekeepers who process large quantities of wax, a solar melter is a highly efficient, energy-free alternative. This device uses the sun's heat to melt wax out of the comb, letting it drip through a filter into a collection pan. While it requires specific equipment, it is a very "hands-off" method for bulk processing.

Making the Right Choice for Your Goal

Your approach should match the quality of your raw wax and your desired outcome.

- If your primary focus is cleaning a small batch of light cappings: The simple single-pot rendering method is perfectly sufficient.

- If your goal is to process dark, dirty brood comb: Plan on performing the single-pot method twice or add a filtering step to achieve high purity.

- If you are a beekeeper with large, regular harvests of wax: Investing in or building a solar melter will save significant time and effort in the long run.

By understanding these simple principles of separation, you can confidently turn any form of raw comb into clean, valuable beeswax.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Combine Wax & Water | Creates medium for separation. |

| 2 | Gently Heat | Melts wax without burning. |

| 3 | Cool Completely | Allows debris to settle. |

| 4 | Separate Wax | Removes clean, solidified wax cake. |

Ready to process your wax harvest efficiently? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality tools needed for every step, from harvesting to rendering. Let us help you scale your operation. Contact our wholesale team today to discuss your equipment needs!

Visual Guide

Related Products

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

People Also Ask

- How does beeswax extraction equipment contribute to the value of beekeeping by-products? Maximize Your Apiary's ROI

- What are the advantages of integrated electric heating tubes compared to traditional steam heating? Boost Your Efficiency

- What is the role of beeswax processing equipment? Maximize Your Apiary Profit Through Full Resource Utilization

- What is the specific function of applying melted natural beeswax? Boost Your Hive Occupancy with Biological Lures

- What is the purpose of applying natural beeswax to the surface of artificial 3D-printed honeybee cell boxes?