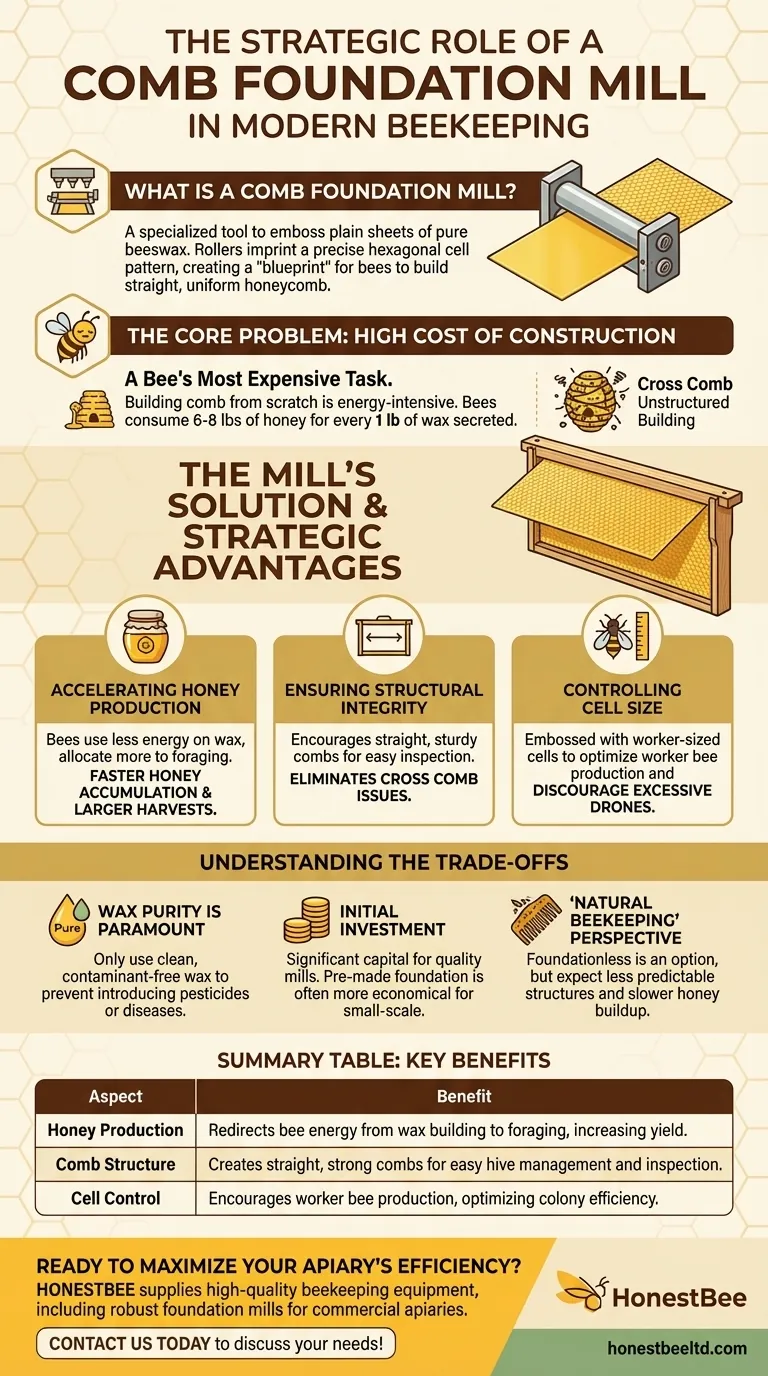

In beekeeping, a comb foundation mill is a specialized tool used to emboss plain sheets of pure beeswax. The mill's rollers imprint a precise hexagonal cell pattern onto the wax, creating what is known as "comb foundation." This embossed sheet is then placed inside a hive frame, providing a guide for the bees to build a straight, uniform, and stable honeycomb.

The core function of a comb foundation mill is to give the beekeeper strategic control over the hive's architecture. By providing a perfect "blueprint," it directs the bees' energy away from wax construction and towards the more productive task of honey production.

The Core Problem: The High Cost of Construction

A Bee's Most Expensive Task

Building comb from scratch is one of the most energy-intensive activities for a honeybee colony. Bees must consume significant amounts of honey—estimates range from 6 to 8 pounds of honey for every pound of wax they secrete.

The Risk of Unstructured Building

Left to their own devices, bees will build comb, but not always in a way that is optimal for the beekeeper. This can lead to "cross comb" (combs built across multiple frames), an overabundance of drone cells, and structurally weak combs that can break during inspection or honey extraction.

How the Foundation Mill Provides the Solution

From Plain Wax to an Embossed Guide

A foundation mill is a simple but effective machine. A beekeeper feeds a thin, plain sheet of purified beeswax through two engraved rollers.

Imprinting the Hexagonal Blueprint

These rollers are meticulously designed to emboss the exact cell outline of a natural honeycomb onto the wax sheet. This pattern serves as an irresistible guide for the worker bees.

Giving the Colony a Head Start

When a frame with foundation is placed in the hive, the bees do not have to secrete wax for the entire structure. They simply use the foundation as a base and begin building the cell walls upwards, saving immense time and energy.

The Strategic Advantages for the Beekeeper

Accelerating Honey Production

Because the bees expend far less energy on wax construction, they can allocate more resources and workforce to foraging for nectar. This directly translates to a faster accumulation of honey and a larger potential harvest.

Ensuring Structural Integrity

Foundation encourages bees to build straight combs within the confines of the frame. These combs are strong, sturdy, and easy to remove for hive inspections. This virtually eliminates the problem of cross comb, which can make a hive nearly impossible to manage.

Controlling Cell Size

Beekeepers typically use foundation embossed with worker-sized cells. This encourages the queen to lay eggs that will become female worker bees—the primary foragers of the colony—while discouraging the production of an excessive number of male drones.

Understanding the Trade-offs

The Purity of the Wax is Paramount

A foundation mill is only as good as the wax fed into it. Using old, dark, or potentially contaminated wax can introduce pesticides or disease pathogens back into your hive. Sourcing or cleaning your own wax is critical.

The Initial Investment

A high-quality comb foundation mill is a significant capital investment. For small-scale or hobbyist beekeepers, purchasing pre-made foundation is often more economical than owning a mill.

The "Natural Beekeeping" Perspective

Some beekeeping philosophies advocate for foundationless beekeeping, allowing bees to build comb entirely on their own terms. While this is a valid approach, it requires accepting the trade-offs: less predictable comb structures, a higher likelihood of drone comb, and often a slower honey buildup.

Making the Right Choice for Your Operation

Deciding whether to use or produce your own comb foundation depends entirely on your beekeeping goals.

- If your primary focus is maximizing honey yield and operational efficiency: Using comb foundation is the industry standard and provides a clear advantage.

- If your primary focus is self-sufficiency and absolute control over hive inputs: Owning a mill to create foundation from your own clean wax is the ultimate path.

- If your primary focus is mimicking the bees' most natural behavior: You may choose foundationless frames, but you must be prepared for more intensive management and potentially lower yields.

Ultimately, understanding the role of comb foundation empowers you to make a deliberate choice that aligns with your specific beekeeping philosophy and goals.

Summary Table:

| Aspect | Benefit |

|---|---|

| Honey Production | Redirects bee energy from wax building to foraging, increasing yield. |

| Comb Structure | Creates straight, strong combs for easy hive management and inspection. |

| Cell Control | Encourages worker bee production, optimizing colony efficiency. |

Ready to maximize your apiary's efficiency? At HONESTBEE, we supply commercial apiaries and distributors with high-quality beekeeping equipment, including robust foundation mills. Enhance your honey production and streamline hive management with our wholesale-focused solutions. Contact us today to discuss your needs!

Visual Guide

Related Products

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Colorful Silicone Beeswax Foundation Mold Mould for Beekeeping

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- What is the economic value of using candle-making equipment and beeswax consumables? Maximize Your Apiary Profits

- What is the primary function of a beeswax flatting and embossing machine? Optimize Your Foundation Production

- What materials are used in a silicone beeswax foundation embossing machine? Durable Steel and Alloy Construction

- What is the importance of soaping the rollers during milling? Prevent Wax Adhesion & Equipment Downtime

- What are the sequential stages of operation for a beeswax flatting and embossing machine? Master High-Quality Wax Sheets