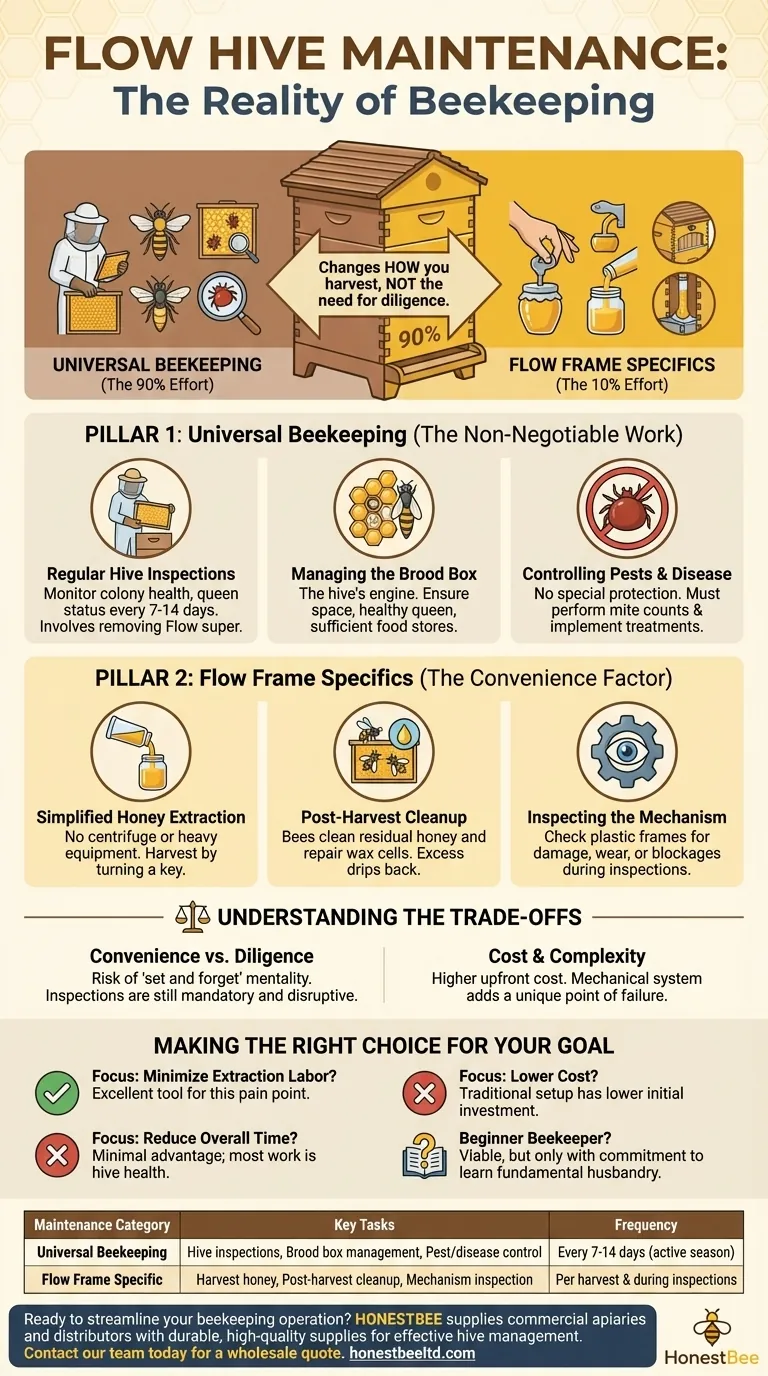

At its core, the maintenance required for a Flow Hive is fundamentally the same as for any standard Langstroth beehive. The innovative Flow Frame system dramatically simplifies the single task of honey extraction, but it does not eliminate the essential, recurring work of colony management and hive inspection. Success still depends on regular, hands-on beekeeping.

The central takeaway is that a Flow Hive changes how you harvest honey, but it does not change the fundamental need to be a diligent beekeeper. The vast majority of your time will still be spent on hive health, not honey collection.

The Two Pillars of Hive Maintenance

To understand the workload, it’s best to separate maintenance into two distinct categories: universal beekeeping tasks and tasks specific to the Flow Hive equipment.

Pillar 1: Universal Beekeeping (The 90% Effort)

This is the non-negotiable work required for any hive, Flow Hive or otherwise. It constitutes the bulk of your time and effort.

The Necessity of Regular Hive Inspections

You must still suit up and open your hive every 7 to 14 days during the active season. These inspections are critical for monitoring the health and productivity of the colony.

During an inspection, you are looking for the queen, checking her laying pattern, and ensuring the colony is free from pests and diseases. This involves removing the Flow super to access the brood box below.

Managing the Brood Box

The Flow Frames make up the honey "super," but the engine of the hive is the brood box below it. This is where the queen lays eggs and the colony raises new bees.

Managing this area—ensuring the colony has enough space, a healthy queen, and sufficient food stores—is identical to the process in a traditional hive.

Controlling Pests and Disease

Pests like Varroa mites and hive beetles, along with diseases like foulbrood, are a constant threat to all honeybee colonies.

A Flow Hive offers no special protection against these issues. You must still perform regular mite counts and implement treatment and prevention strategies as needed.

Pillar 2: Flow Frame Specifics (The 10% Effort)

This is where the Flow Hive's design alters the beekeeper's workflow, primarily focused on the convenience of harvesting.

Simplified Honey Extraction

The primary benefit of the Flow Hive is the removal of traditional honey house equipment. You do not need a centrifuge extractor, uncapping knives, or filters.

Harvesting is done by inserting a tool and turning a key, which splits the cells and allows honey to drain out via a tube, directly into your jar.

Post-Harvest Cleanup

After a harvest, the bees will typically repair the wax cells and clean up any residual honey left in the Flow Frames.

Any excess honey in the collection trough that doesn't flow out is designed to drip back into the hive through a small gap for the bees to consume.

Inspecting the Flow Frame Mechanism

While durable, the plastic Flow Frames are a mechanical system. During your regular inspections, you should check them for any signs of damage, wear, or blockages.

Ensuring the frame mechanism operates smoothly is key to preventing leaks or a failed harvest.

Understanding the Trade-offs

The convenience of a Flow Hive comes with important considerations that every prospective beekeeper must weigh.

The Myth of "No-Disturbance" Beekeeping

While the act of harvesting is far less disruptive to the bees, the necessary hive inspections are just as disruptive as in a traditional hive. You still need to open the hive, smoke the bees, and pull out frames from the brood box.

Convenience vs. Diligence

The greatest risk of the Flow Hive, especially for beginners, is the temptation to neglect essential hive inspections. The "set and forget" marketing can create a false sense of security, leading new beekeepers to believe the hive manages itself. This is a path to colony failure.

Cost and Complexity

Flow Hives have a significantly higher upfront cost compared to a basic Langstroth setup. You are paying a premium for the convenience of the harvesting mechanism. This mechanical complexity also introduces a unique point of failure not present in simple wax-and-wood frames.

Making the Right Choice for Your Goal

The Flow Hive is a tool, and its value depends entirely on your beekeeping objectives.

- If your primary focus is minimizing the labor and mess of honey extraction: The Flow Hive is an excellent tool that directly addresses this pain point.

- If your primary focus is reducing the overall time commitment of beekeeping: The Flow Hive offers a minimal advantage, as most work is related to hive health inspections.

- If your primary focus is cost: A traditional Langstroth hive and separate extraction equipment will have a lower initial investment.

- If you are a beginner: The Flow Hive is a viable option, but only if you understand that it does not replace the need to learn and practice fundamental bee husbandry.

Ultimately, successful beekeeping is the result of attentive and consistent hive stewardship, regardless of the equipment you choose.

Summary Table:

| Maintenance Category | Key Tasks | Frequency |

|---|---|---|

| Universal Beekeeping | Hive inspections, Brood box management, Pest/disease control | Every 7-14 days (active season) |

| Flow Frame Specific | Harvest honey, Post-harvest cleanup, Mechanism inspection | Per harvest & during inspections |

Ready to streamline your beekeeping operation?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, high-quality supplies needed for effective hive management—whether you use traditional Langstroth hives or innovative systems like the Flow Hive. Our wholesale-focused operations ensure you get the reliable equipment your business depends on.

Contact our team today to discuss your beekeeping supply needs and request a wholesale quote.

Visual Guide

Related Products

- Automatic Honey Flow Beehive 4 Frame Mini Hive for Beekeeping

- 7 x Auto Bee Flow Hive Frames Plastic Beekeeping Hive Box Supplies

- Honey Flow Garden Bee Hive Flow Hive Best Beehive for Beginners

- Stainless Steel Triangle Support Honey Strainer and Filters

- Professional Drop-Style Hive Handles for Beekeeping

People Also Ask

- What are the technical purposes of transparent plastic channels and baffle structures in an automated beehive monitoring system?

- How does the Flow Hive compare to traditional hives for management flexibility? Control vs. Convenience

- How does an Auto Flow Beehive improve safety for beekeepers? 5 Key Benefits for Sting-Free Harvesting

- What are the main components of a Flow Hive? Discover the Innovative Beekeeping System

- What is a major advantage of using split-cell frames for honey extraction? Simplify Harvesting & Cut Equipment Costs

- What is the primary function of an automated honey harvesting frame? Streamline Your In-Situ Honey Extraction

- How do the costs of Langstroth and Flow Hives compare? Uncover the True Investment for Your Apiary

- How do the hive bodies of Flow Hives and Langstroth hives compare? Understanding the Core Differences