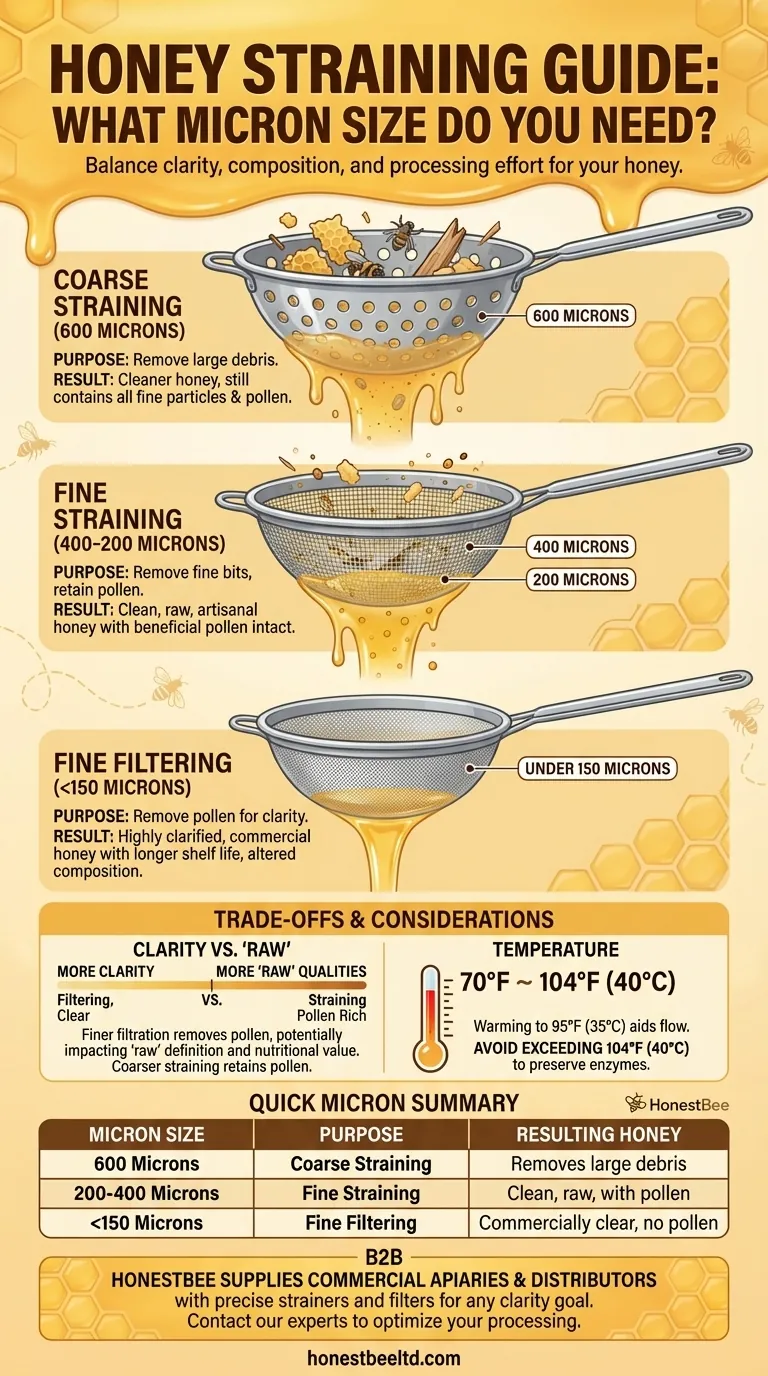

For straining honey, the ideal micron size depends entirely on your goal. A coarse 600-micron strainer is used to remove large debris like wax and bee parts, while a finer 200-micron strainer will remove fine particles while retaining beneficial pollen. To produce commercially clear honey, you must filter below 150 microns, which will remove the pollen.

The choice of a micron size is not just about cleanliness; it's a decision between preserving the "raw" qualities of honey, rich with pollen, and producing a highly clarified, stable liquid. Your goal determines the right tool for the job.

The Goal of Straining: Debris vs. Pollen

The term "straining" can be misleading because it covers a wide range of outcomes. The fundamental question is what you want to remove and what you want to keep.

Coarse Straining (600 Microns)

This is the essential first step for any honey harvest. A 600-micron strainer is designed to catch the big, undesirable contaminants.

Its sole purpose is to remove large debris such as wax cappings, wood splinters from the hive, and unfortunate bee parts, leaving everything else behind. This is the minimum level of straining required.

Fine Straining (400 to 200 Microns)

This is the most common range for beekeepers who want clean, artisanal, and "raw" honey. A 400-micron strainer is a good intermediate step, and a 200-micron strainer is often the final stage.

This level of straining removes fine wax particles and other suspended bits, resulting in a clearer product. Critically, it leaves the vast majority of beneficial pollen grains intact, which is a key characteristic of raw honey.

Fine Filtering (Under 150 Microns)

Once you go below approximately 150 microns, you are no longer just straining—you are filtering. This process removes the pollen from the honey.

This is standard practice for large commercial producers who prioritize a perfectly clear appearance and a longer shelf life before crystallization. However, this process alters the natural state of the honey.

Understanding the Trade-offs

Choosing a micron size involves balancing clarity, composition, and processing effort. There is no single "best" size, only the right size for your specific purpose.

Clarity vs. "Raw" Honey

Finer filtration produces the crystal-clear honey many consumers recognize from supermarket shelves. Removing fine particles, especially pollen, can also slow down the rate of crystallization.

Conversely, honey that is only coarsely strained (e.g., to 200 microns) will appear slightly cloudier because it retains its pollen. Many health-conscious consumers specifically seek out this type of honey for its perceived nutritional benefits.

The Impact of Temperature

Honey is highly viscous, meaning it flows slowly. The finer the strainer, the more difficult it is for honey to pass through.

Gently warming your honey to around 95°F (35°C) will significantly lower its viscosity and speed up the straining process, especially with finer meshes. Be cautious not to exceed 104°F (40°C), as higher temperatures can destroy beneficial enzymes and degrade the honey's quality.

Labeling and Definitions

The term "raw honey" generally implies it has not been heated to high temperatures or filtered to the point of removing its natural pollen content. Using a filter finer than 150 microns may mean your honey no longer meets the common or even legal definition of "raw" in some regions.

Choosing the Right Micron for Your Honey

Your equipment choice should be a direct reflection of the final product you want to create.

- If your primary focus is raw, artisanal honey: Use a 200-micron strainer as your final step to produce a clean but pollen-rich product.

- If your primary focus is maximum clarity and stability: Use a filter below 150 microns, understanding that this will remove the pollen and alter the honey's natural composition.

- If you are a beginner on a budget: Start with a simple 600-micron strainer to remove the largest debris; you can always strain it again later if you desire more clarity.

Ultimately, consciously choosing your filtration level empowers you to produce honey that perfectly aligns with your standards.

Summary Table:

| Micron Size | Purpose | Resulting Honey |

|---|---|---|

| 600 Microns | Coarse Straining | Removes large debris (wax, bee parts) |

| 200-400 Microns | Fine Straining | Clean, raw honey with pollen intact |

| <150 Microns | Fine Filtering | Commercially clear, pollen-removed honey |

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the precise strainers and filters needed to achieve any honey clarity goal. Whether you need 600-micron strainers for debris removal or sub-150-micron filters for crystal-clear commercial honey, our wholesale-focused operations provide reliable, high-quality equipment. Let us help you optimize your honey processing—contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Professional Honey Filter with Tripod Support Stand

- Professional Stainless Steel Honey Filter with Support Handle

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Two-Stage Plastic Honey Filter for Buckets

People Also Ask

- What size mesh to strain honey? A Guide to the Standard Double-Sieve Method

- Why is the use of high-density filter cloth necessary during the processing of stingless bee honey? Ensure Pure Quality

- Why is it important to inspect and replace filters in honey filtering equipment? Protect Your Honey Quality & Equipment

- Why is a Synthetic Cloth Mesh used in honey filtration? Ensure Purity and Chemical Integrity in Your Honey Samples

- What is the function of a 30 micrometer pore size nylon mesh filter? Essential Guide to Honey Sample Preparation