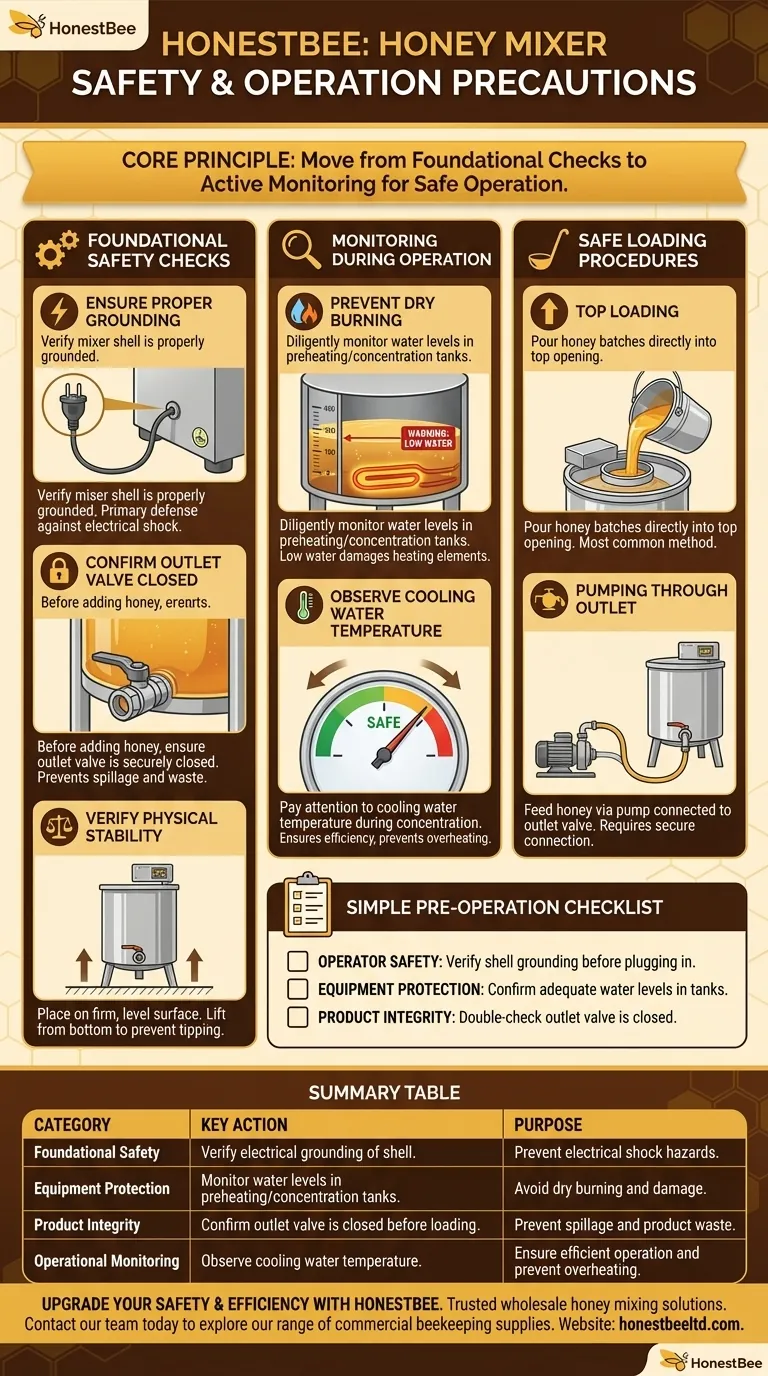

Proper operation of a honey mixer requires a combination of electrical safety, procedural discipline, and active monitoring. Key precautions include ensuring the machine's shell is properly grounded to prevent electrical hazards, confirming the outlet valve is closed before adding honey, and closely monitoring water levels in any preheating or concentration tanks to avoid equipment damage from dry burning.

The core principle for safely operating a honey mixer is to move from foundational checks to active monitoring. You must first verify the machine's electrical and physical setup before transitioning to carefully observing its operational parameters like water levels and temperatures.

Foundational Safety Checks

Before powering on or loading the mixer, a few fundamental checks are essential to prevent immediate hazards and product loss.

Ensure Proper Electrical Grounding

The single most critical safety step is to verify the mixer's shell is properly grounded. This is your primary defense against electrical shock in the event of an internal fault.

Confirm the Outlet Valve is Closed

Before adding honey from the top opening, always ensure the outlet valve is securely closed. This simple step prevents spillage, product waste, and a significant clean-up effort.

Verify Physical Stability

While the mixer is designed to be stable, it should always be placed on a firm, level surface. When lifting or moving the unit, always lift from the bottom to maintain its center of gravity and prevent tipping.

Monitoring During Active Operation

Once the mixer is running, your focus shifts from setup to monitoring. This is crucial for protecting the equipment, especially if your model includes heating or concentration functions.

Prevent Dry Burning

If your mixer has preheating or concentration tanks, you must diligently monitor the water level. Allowing the water to run low can lead to a "dry burn," which can permanently damage the heating elements.

Observe Cooling Water Temperature

During the concentration process, pay close attention to the temperature of the cooling water. This ensures the system is operating efficiently and helps prevent the equipment from overheating.

Safe Loading Procedures

There are two primary methods for loading honey into the mixer, each with its own considerations.

Loading from the Top

This is the most common method. After ensuring the outlet valve is closed, you can simply pour honey batches directly into the top opening of the mixer.

Pumping Through the Outlet

Alternatively, honey can be fed into the machine using a pump connected to the outlet valve. This requires a secure connection to prevent leaks under pressure.

A Simple Pre-Operation Checklist

Use this checklist to ensure a safe and efficient workflow every time.

- For Operator Safety: Verify the machine's shell is properly grounded before plugging it in.

- For Equipment Protection: If your unit heats, confirm adequate water levels in the tanks to prevent dry burning.

- For Product Integrity: Double-check that the outlet valve is closed before you begin loading honey.

Following these deliberate steps will ensure safe operation, protect your equipment, and maintain the quality of your product.

Summary Table:

| Precaution Category | Key Action | Purpose |

|---|---|---|

| Foundational Safety | Verify electrical grounding of the shell. | Prevent electrical shock hazards. |

| Equipment Protection | Monitor water levels in preheating/concentration tanks. | Avoid dry burning and damage to heating elements. |

| Product Integrity | Confirm outlet valve is closed before loading honey. | Prevent spillage and product waste. |

| Operational Monitoring | Observe cooling water temperature during concentration. | Ensure efficient operation and prevent overheating. |

Upgrade your honey processing safety and efficiency with HONESTBEE.

As a trusted supplier for commercial apiaries and equipment distributors, we provide robust, wholesale-focused honey mixing solutions designed for high-volume operations. Our equipment incorporates the critical safety features outlined above, helping you protect your investment, your product, and your team.

Let HONESTBEE's expertise and reliable equipment support your business growth. Contact our team today to discuss your specific needs and explore our range of commercial beekeeping supplies.

Visual Guide

Related Products

- Economy Honey Homogenizer Mixer and Melting Machine for Beekeeping

- Modern Stainless Steel Honey Dipper Stirrer

- Natural Wood Honey Dipper for Tea Coffee and Desserts

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Stainless Steel Honey Press Wax Press with Tank

People Also Ask

- How does a high-speed vortex mixer influence extraction efficiency? Maximize Honey Pretreatment Speed

- Why Use a Water Bath for Honey-Syrup Mixing? Ensure Lab Accuracy and Sample Integrity

- Why is specialized honey emulsification or stirring equipment utilized to produce cream honey? Elevate Your Honey Value

- What is the primary role of a honey decomposing machine? Master Value-Added Honey Production with Precise Blending

- What is the necessity of industrial-grade mixing equipment for sodium humate syrup? Ensure Apiary Health with Precision

- How do commercial high-efficiency mixers ensure nutritional consistency? Precision Blending for Superior Bee Patties

- Why is the use of industrial-grade homogenization equipment essential when blending processed fruits with rapeseed honey?

- What is the function of a temperature-controlled stirring device for inverted sugar syrup? Safe Bee Feed Preparation