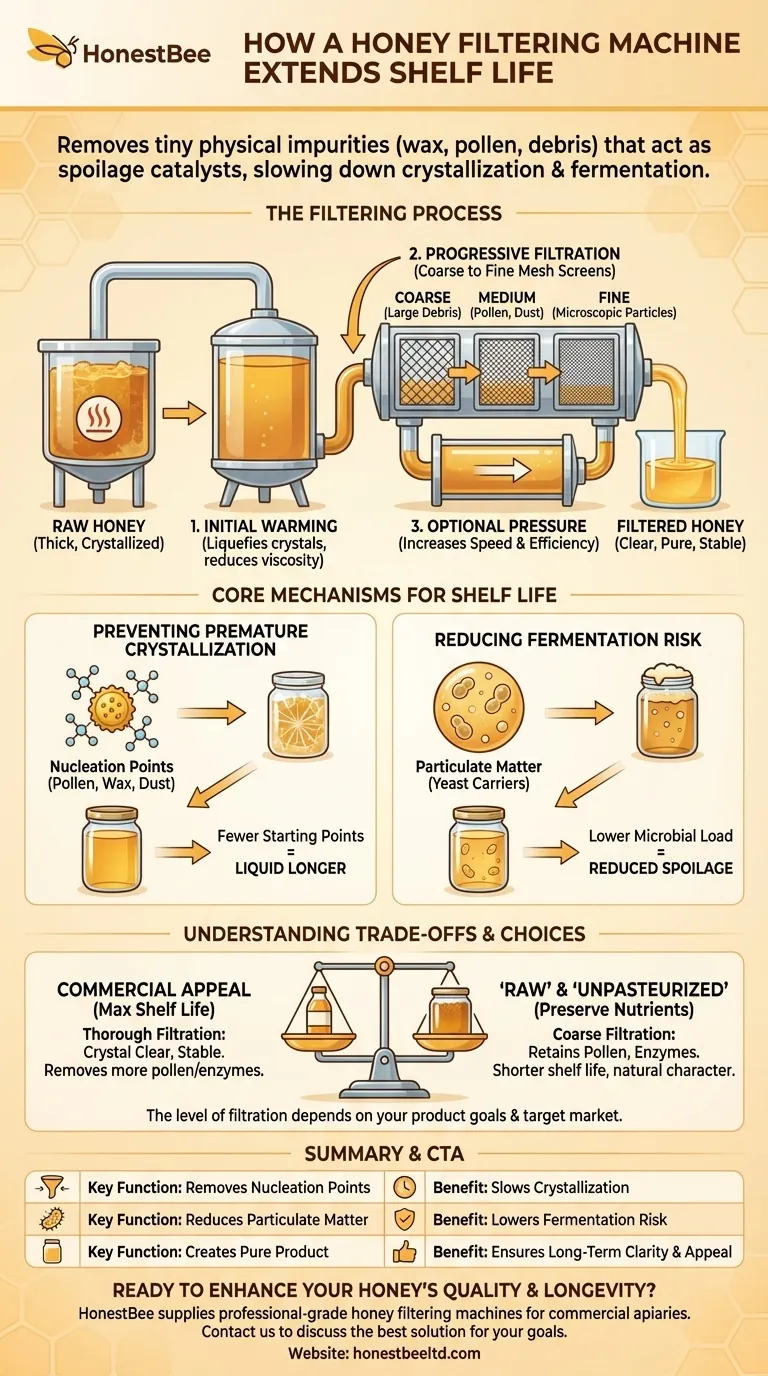

At its core, a honey filtering machine extends shelf life by removing the tiny physical impurities that act as catalysts for spoilage. By systematically straining out particles like wax, pollen grains, and microscopic debris, the machine significantly slows down the two main processes that degrade honey over time: crystallization and fermentation.

The true role of a honey filtering machine is not just cleaning; it is a strategic process of controlling the physical and chemical stability of honey, ensuring it remains in its ideal liquid state for much longer.

How the Filtering Process Works

A honey filtering machine is more than just a simple strainer. It employs a multi-stage process designed to purify the honey efficiently without damaging its fundamental qualities.

The Initial Warming Stage

Raw honey is often thick and may have already begun to crystallize. The process begins by gently heating the honey in a tank to a controlled temperature.

This warming doesn't pasteurize the honey; it simply liquefies any existing sugar crystals and reduces the honey's viscosity, allowing it to flow smoothly through the filters.

Progressive Filtration

The warmed honey then passes through a series of mesh screens. These screens become progressively finer at each stage.

The initial screens catch large debris like bee parts and chunks of wax. Subsequent, finer screens trap smaller particles like pollen and dust, resulting in a clear, pure final product.

Optional Pressure Systems

Some advanced machines use pressure or vacuum systems to push or pull the honey through the filters. This increases the speed and efficiency of the operation, especially when dealing with large volumes of honey.

The Core Mechanisms for Extending Shelf Life

Removing physical impurities directly counters the natural processes that cause honey to "go bad" or become undesirable for consumers.

Preventing Premature Crystallization

Crystallization is a natural process where the glucose in honey separates from water and forms solid crystals. While not a sign of spoilage, most consumers prefer liquid honey.

Fine particles—like dust, pollen grains, and tiny wax fragments—act as nucleation points. Sugar molecules latch onto these particles, which kickstarts and accelerates the crystallization process. By removing them, filtration leaves fewer starting points for crystals to form, keeping the honey liquid for longer.

Reducing Fermentation Risk

Fermentation occurs when naturally present osmophilic yeasts consume the honey's sugars and produce alcohol and carbon dioxide. This is a true form of spoilage.

While filtering does not sterilize the honey, it does remove some of the particulate matter that can carry yeast cells, thus lowering the overall microbial load and reducing the chances of fermentation.

Understanding the Trade-offs

While filtering offers clear benefits for shelf life and appearance, it's a process with important considerations. The decision to filter, and to what degree, is a critical one for any beekeeper or producer.

The Risk to Natural Components

Aggressive, ultra-fine filtering can remove more than just debris. It can also strip out a significant amount of pollen, which many consumers value for its potential health benefits and for verifying the honey's floral origin.

Over-filtering, especially when combined with high heat, can also risk damaging the natural enzymes that define raw honey.

The "Raw" vs. "Filtered" Distinction

There is a strong market for raw and unfiltered honey. Consumers seeking this product specifically want the pollen, enzymes, and trace amounts of propolis and wax that filtration removes.

For producers serving this niche, filtering is intentionally minimized to only remove large, undesirable debris while preserving the honey's natural character.

Making the Right Choice for Your Goal

The level of filtration you should use depends entirely on your product goals and target market.

- If your primary focus is maximum shelf life and commercial appeal: A thorough filtration process is essential to ensure long-term stability and the crystal-clear appearance that mainstream consumers expect.

- If your primary focus is selling "raw" or "unpasteurized" honey: Use only coarse filtering to remove large impurities (like bee wings or wood splinters) while leaving beneficial pollen and enzymes intact.

Ultimately, using a honey filtering machine is a deliberate choice that defines the final character and longevity of your product.

Summary Table:

| Key Function | Benefit for Shelf Life |

|---|---|

| Removes Nucleation Points (e.g., pollen, wax) | Slows down/prevents premature crystallization |

| Reduces Particulate Matter | Lowers microbial load, reducing fermentation risk |

| Creates a Pure, Stable Product | Ensures long-term clarity and consumer appeal |

| Preserves Quality (with controlled filtering) | Maintains desired 'raw' or 'commercial' product characteristics |

Ready to enhance your honey's quality and longevity?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with professional-grade honey filtering machines and a full range of beekeeping supplies. Our wholesale-focused operations ensure you get the durable, efficient equipment needed to produce a stable, high-quality product that meets market demands.

Contact HONESTBEE today to discuss the best filtering solution for your apiary's goals!

Visual Guide

Related Products

- Electric Double Wall Honey Filtering Machine Purifier Equipment for Honey Processing Plant

- Professional Stainless Steel Honey Filtering Machine with Water Bath Heating for Beekeeping

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Manual Honey Filling Machine Bottling Machine for Honey

People Also Ask

- Why are stainless steel filters essential during the initial purification phase of honey processing? Ensure Purity

- What are the technical advantages of using professional filtration for honey? Optimize Clarity and Quality

- What is the primary purpose of multi-stage honey filtration? Achieve Visual Clarity and Purity Without Compromise

- How does a stainless steel filtration system protect product quality? Ensure Purity & Stability in Honey Processing

- How does the decanting process in settling tanks contribute to honey purification? Achieve High Clarity Naturally