In short, the nozzle is the final control point for quality and efficiency in honey filling. Its design is fundamentally responsible for dispensing honey into containers cleanly, accurately, and without waste. A well-designed nozzle directly prevents costly product loss from drips and ensures a professional, mess-free final product.

The nozzle is not merely a spout; it is a precision instrument engineered to manage the unique challenges of a viscous, sticky product like honey. The right nozzle design is a critical decision that directly impacts profitability by minimizing waste, maximizing speed, and ensuring operational cleanliness.

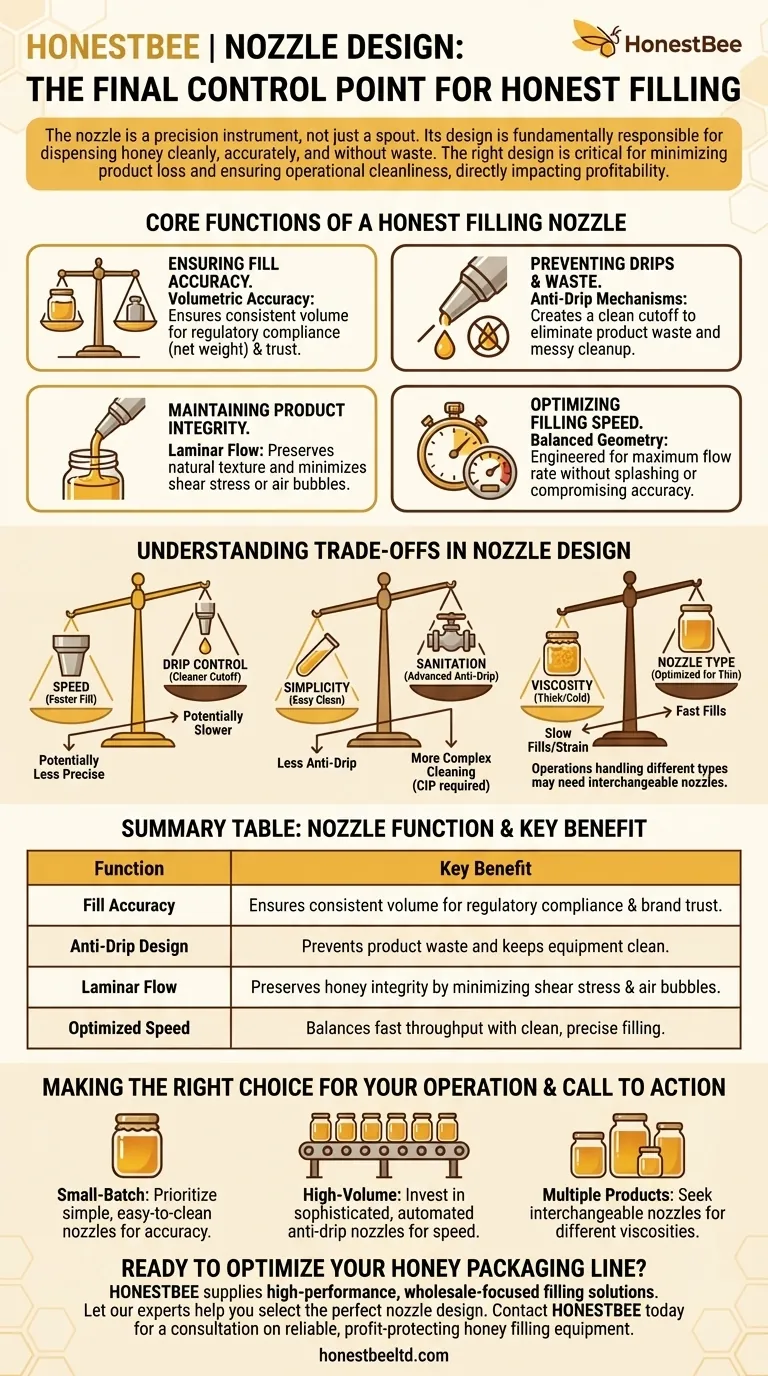

The Core Functions of a Honey Filling Nozzle

A nozzle's role extends far beyond simply directing honey. It must perform several critical functions simultaneously to ensure an efficient and high-quality packaging process.

Ensuring Fill Accuracy and Consistency

The primary job of the nozzle is to execute a clean cutoff of the honey flow. This ensures that every container receives the exact same volume of product, a concept known as volumetric accuracy.

This precision is crucial for regulatory compliance (net weight requirements) and for maintaining customer trust. Inconsistent fill levels can appear unprofessional and erode brand confidence.

Preventing Drips and Product Waste

Honey's high viscosity and stickiness make it prone to dripping after the fill cycle ends. Modern nozzles incorporate anti-drip mechanisms to solve this.

These can be mechanical valves that snap shut or designs that use pressure and surface tension to create a clean break in the honey stream. Eliminating drips prevents product waste, keeps containers and equipment clean, and significantly reduces cleanup time.

Maintaining Product Integrity

Honey can be damaged by excessive force or agitation, a phenomenon known as shear stress. A poorly designed nozzle can introduce air bubbles or alter the honey's delicate texture.

A proper nozzle design promotes laminar flow—a smooth, non-turbulent stream. This preserves the natural quality and appearance of the honey from the tank to the final container.

Optimizing Filling Speed

While precision is key, so is throughput. The nozzle's internal diameter and geometry are carefully engineered to allow the fastest possible flow rate without causing splashing or compromising fill accuracy. This balance is essential for maintaining a high-speed production line.

Understanding the Trade-offs in Nozzle Design

Choosing a nozzle involves balancing competing priorities. There is no single "best" design; the optimal choice depends on the specific operational goals.

Speed vs. Drip Control

A nozzle with a larger opening can fill jars faster, increasing throughput. However, a wider stream of honey is often harder to cut off cleanly, increasing the potential for drips if the anti-drip mechanism is not perfectly matched.

Conversely, a narrower nozzle offers superior drip control and precision but will fill containers more slowly, potentially creating a bottleneck in a high-volume operation.

Simplicity vs. Sanitation

Simple, straight-tube nozzles are incredibly easy to disassemble and clean. This is a major advantage for maintaining high sanitation standards, especially for raw or unfiltered honey.

More complex anti-drip nozzles with internal springs, seals, or moving parts offer superior performance but can create challenges for cleaning. These components must be designed for easy disassembly or be compatible with Clean-In-Place (CIP) systems to prevent contamination.

Product Viscosity vs. Nozzle Type

The viscosity of honey changes dramatically with its temperature and floral source. A nozzle optimized for thin, warm honey may struggle with thick, cold, or crystallized honey, leading to slow fills or motor strain on the filling machine.

Operations that handle different types of honey may require machines with interchangeable nozzles to adapt to changing product characteristics efficiently.

Making the Right Choice for Your Operation

The ideal nozzle is one that aligns with your production scale, product type, and business priorities.

- If your primary focus is small-batch, artisanal quality: Prioritize a simple, easy-to-clean nozzle that provides excellent accuracy, even if it operates at a slower speed.

- If your primary focus is high-volume industrial production: Invest in a system with a sophisticated, automated anti-drip nozzle engineered for maximum speed and minimal waste.

- If your primary focus is versatility for multiple products: Seek a filling machine that offers a range of interchangeable nozzles to handle different viscosities and container sizes effectively.

Ultimately, selecting the right nozzle is a strategic decision that protects your product, your process, and your profitability.

Summary Table:

| Nozzle Function | Key Benefit |

|---|---|

| Fill Accuracy | Ensures consistent volume for regulatory compliance and brand trust. |

| Anti-Drip Design | Prevents product waste and keeps equipment clean. |

| Laminar Flow | Preserves honey integrity by minimizing shear stress and air bubbles. |

| Optimized Speed | Balances fast throughput with clean, precise filling. |

Ready to optimize your honey packaging line?

The right nozzle is a precision component that directly impacts your bottom line by minimizing waste and maximizing efficiency. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-performance, wholesale-focused filling solutions they need to scale.

Let our experts help you select the perfect nozzle design for your specific honey viscosity and production volume.

Contact HONESTBEE today for a consultation on reliable, profit-protecting honey filling equipment.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Honey Gate Valve with Ergonomic Ball Handle Plastic Bee Honey Tap for Beekeeping Bottling and Honey Extractor Equipment

- Premium Diamond-Faceted Glass Honey Dispenser

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

- Honeycomb Style Drip Free Honey Dispenser

People Also Ask

- What role does honey-filling and processing machinery play in pollination? Maximize Apiary ROI & Economic Stability

- What role do honey filling machines play in meeting quality standards? Ensure Global Export Compliance

- How do industrial honey filling machines ensure compliance? Master Quality Control for Global Export

- Why is a specialized honey filling machine necessary? Meet International Standards and Preserve Premium Honey Quality

- What role do automated honey-filling machines play in trade standards? Ensure Global Export Compliance & Consistency