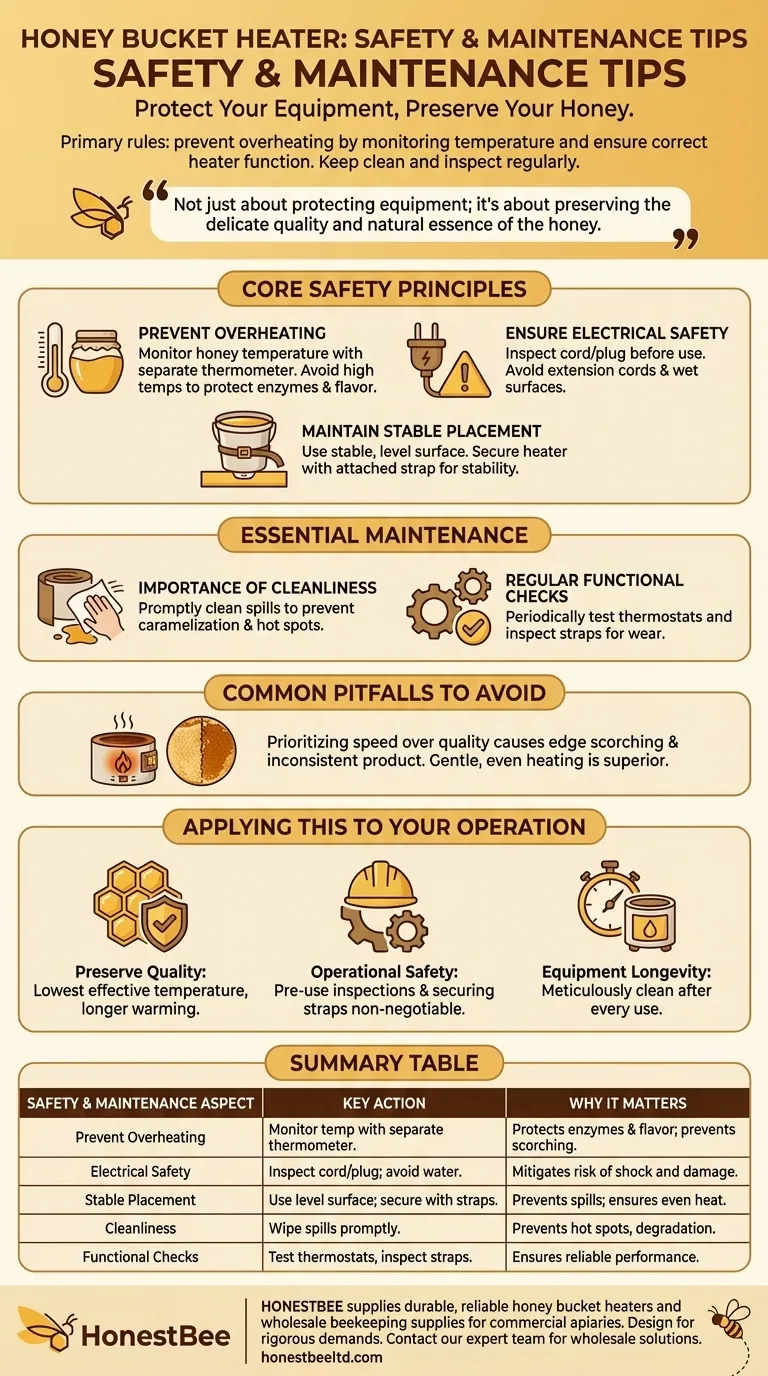

To safely use a honey bucket heater, the primary rules are to prevent overheating by regularly monitoring the honey's temperature and ensuring the heater itself is functioning correctly. For maintenance, keep the heater clean from spills and conduct routine inspections of its components to ensure longevity and consistent performance.

The core principle behind honey heater safety and maintenance is not just about protecting the equipment; it's about preserving the delicate quality and natural essence of the honey itself. Proper use ensures both safety and a superior final product.

Core Safety Principles in Detail

Operating any heating element requires attention to detail. With honey, the goal is to gently reliquefy the product without degrading its natural properties.

Preventing Overheating

Overheating is the most significant risk to your honey's quality. High temperatures can destroy the beneficial enzymes and alter the delicate flavor profile you've worked hard to produce.

To prevent this, consistently monitor the temperature of the honey, not just the setting on the heater. Use a separate thermometer to verify the honey is warming gently and not exceeding the desired temperature.

Ensuring Electrical Safety

Like any electrical appliance, your honey heater requires a safe operating environment. Before each use, perform a quick visual inspection of the power cord and plug for any signs of fraying or damage.

Always plug the heater directly into a suitable outlet. Avoid using damaged extension cords, and never operate the unit near water or on a wet surface.

Maintaining Stable Placement

A full honey bucket is heavy and presents a significant spill risk if knocked over, especially when warm. Ensure the bucket is on a stable, level surface where it won't be disturbed.

Many heaters come with an attached strap. Use this feature to secure the heating wrap firmly to the bucket, which not only improves stability but also ensures better heat transfer.

Essential Maintenance for Longevity

Proper maintenance extends the life of your heater and guarantees it performs as expected every season. These simple checks can save you from equipment failure during a critical time.

The Importance of Cleanliness

Honey spills or drips are inevitable. It is crucial to clean them off the heater's surface promptly.

If honey is left on the heater, it can caramelize and burn, creating hot spots that lead to uneven heating and potentially damaging the heater itself. A clean surface ensures uniform heat distribution.

Regular Functional Checks

Periodically, you must confirm the heater is functioning correctly. This goes beyond checking the power cord.

Ensure any thermostats or temperature controls are responding accurately. Check straps and buckles for wear and tear to ensure they can still hold the heater securely in place.

Common Pitfalls to Avoid

The most common mistake is prioritizing speed over quality. Attempting to heat a crystallized bucket of honey too quickly on a high setting can scorch the honey near the edges while the center remains solid.

This creates an inconsistent product and damages the very quality you are trying to preserve. Gentle, even heating is always the superior method, even if it takes more time.

Applying This to Your Operation

Your approach to using a honey heater should align directly with your primary goal, whether you are a hobbyist or a professional.

- If your primary focus is preserving maximum honey quality: Use the lowest effective temperature setting and allow for a longer, slower warming period to ensure enzymes and flavor are protected.

- If your primary focus is operational safety and efficiency: Make pre-use inspections of your equipment a non-negotiable part of your workflow and always use securing straps.

- If your primary focus is equipment longevity: Prioritize keeping the heater meticulously clean after every use to prevent material degradation and ensure efficient performance for years.

Ultimately, treating your honey heater with the same care and attention you give your bees and their honey will always yield the best results.

Summary Table:

| Safety & Maintenance Aspect | Key Action | Why It Matters |

|---|---|---|

| Preventing Overheating | Monitor honey temperature with a separate thermometer. | Protects delicate enzymes and flavor; prevents scorching. |

| Electrical Safety | Inspect power cord and plug before each use; avoid water. | Mitigates risk of electrical shock and equipment damage. |

| Stable Placement | Use on a level surface; secure heater with straps. | Prevents dangerous spills and ensures even heat distribution. |

| Cleanliness | Wipe off honey spills promptly after use. | Prevents caramelization, hot spots, and material degradation. |

| Functional Checks | Periodically test thermostats and inspect straps/buckles. | Ensures reliable performance and identifies wear before failure. |

Maximize the safety, efficiency, and lifespan of your honey warming equipment.

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with durable, reliable honey bucket heaters and a full range of wholesale beekeeping supplies. Our equipment is designed for the rigorous demands of commercial operations, helping you protect your valuable honey crop and streamline your workflow.

Contact our expert team today to discuss your specific needs and discover how our wholesale-focused solutions can benefit your operation.

Visual Guide

Related Products

- Stainless Steel Heated Honey Tank Warming Heating Tank

- Silicone Rubber Honey Drum Heating Belt

- Professional Honey Storage Tank with Agitation System

- Economy Honey Homogenizer Mixer and Melting Machine for Beekeeping

- Stainless Steel Honey Storage Tank with Lid for Honey

People Also Ask

- What methods are used to heat honey, and what precaution should be taken? Expert Guide to Safe Honey Liquefaction

- What factors should be considered when choosing a honey bucket heater? Protect Honey Quality with Precise Heat

- What are the key features to look for in a honey warming source? Preserve Honey Quality with Gentle, Even Heat

- How does industrial constant temperature heating equipment affect the biological activity of honey? Optimize G-CSF Output

- How to get crystallized honey out of frames? Safely reliquefy honey without damaging comb.

- How do high-precision electric heating devices function in bee colony management? Optimize Spring and Winter Success

- What advantages does an ultrasonic cleaner offer over traditional heating for honey? Preserve Quality and Nutrients

- Why is the 150°C high-temperature paraffin dipping process recommended? Master Beehive Disinfection and Preservation