To use a honey extractor without causing damage, you must ensure every load of frames is perfectly balanced and that you only use frames with internal support, like wire or plastic foundation. An unbalanced load creates violent vibrations that can break the extractor, while the intense centrifugal force will tear apart any comb that is not properly reinforced.

Preventing damage isn't just about careful operation; it's about a holistic approach. Success hinges on ensuring your equipment is appropriate for the task, your frames are prepared correctly, and your operational technique respects the physical forces at play.

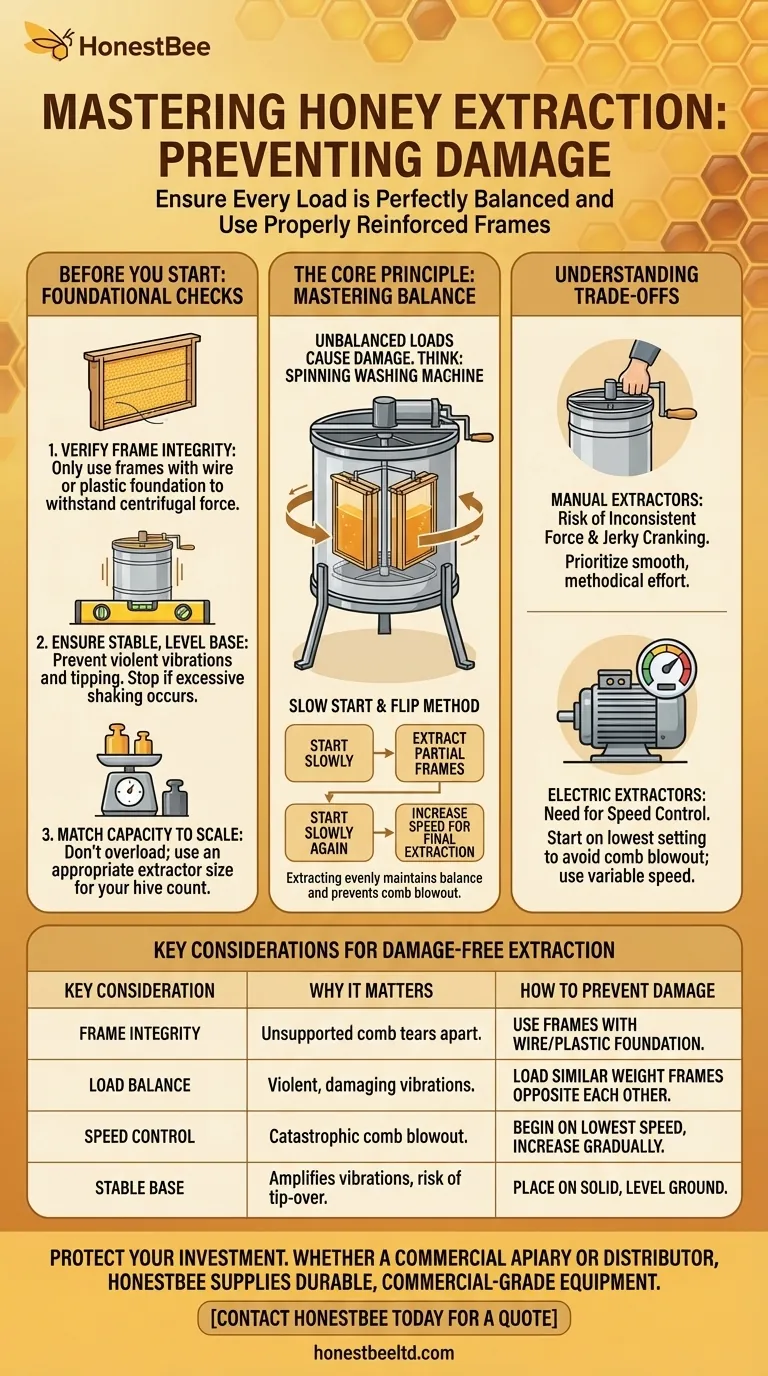

Foundational Checks: Preventing Damage Before You Start

Before you even place a frame in the extractor, a few preparatory steps are essential. Skipping these is the most common source of preventable and costly damage.

Verify Your Frame Integrity

The force generated inside an extractor is immense. Frames containing comb built without a plastic foundation or internal wiring cannot withstand this force.

The comb will tear away from the wooden frame, resulting in a catastrophic failure. This not only destroys the comb but creates a significant mess and can unbalance the load, jeopardizing the machine itself.

Ensure a Stable, Level Base

Your extractor must be on solid, level ground. During operation, especially if the load is even slightly imperfect, the machine will want to "walk" or vibrate.

An unstable or unlevel surface will amplify these vibrations, potentially causing the extractor to tip over, which can damage the motor, the drum, and the frames inside. If you see your extractor vibrating excessively, stop it immediately and re-balance the load.

Match Extractor Capacity to Your Scale

Using an extractor that is too small for your number of hives creates pressure to work too quickly. This often leads to improperly balanced loads and rushing the speed-up process.

As a general guide, an extractor can typically handle a harvest from about double the number of hives as its frame capacity (e.g., a 4-frame extractor is suitable for up to 8 hives). Pushing your equipment beyond its intended workload is a direct path to premature wear and failure.

The Core Principle: Mastering Centrifugal Balance

The single most critical factor during operation is balance. Think of your extractor like a washing machine on a high-speed spin cycle—an unbalanced load is noisy, inefficient, and destructive.

The Critical Importance of Balance

An unbalanced set of frames will cause the extractor to shudder violently. This places enormous stress on the basket, the central shaft, the bearings, and the motor.

Over time, this stress will lead to component failure. In a worst-case scenario, it can happen immediately, breaking welds or shearing parts.

How to Properly Load Frames

Always load frames of similar weight directly opposite each other. A heavy, full frame of honey should be balanced by another heavy frame, not an empty or partially filled one.

If you have an odd number of frames or frames with very different weights, it is better to run the extractor with fewer frames that are properly balanced than to run it full and unbalanced.

The "Slow Start and Flip" Method

Never start the extractor at full speed. Begin slowly, allowing a portion of the honey to be extracted from one side of the comb first.

After this initial spin, stop the extractor, flip the frames to face the other way, and repeat. This two-sided, slow-start process extracts honey more evenly, which helps maintain balance and prevents the weight of the honey from blowing out the center of the comb. Once honey is partially extracted from both sides, you can increase the speed for the final extraction.

Understanding the Trade-offs

The type of extractor you use—manual or electric—introduces different risks that you must manage to prevent damage.

Manual Extractors: The Risk of Inconsistent Force

Manual extractors rely on your physical effort. It can be difficult to maintain a smooth, consistent speed, and jerky or overly aggressive cranking can put sudden stress on the frames and gears.

Furthermore, physical fatigue can lead to poor decision-making and mistakes, especially during a long extraction day.

Electric Extractors: The Need for Speed Control

The power of an electric motor is a major benefit, but it's also a risk. Starting an electric extractor too quickly is the easiest way to cause a "comb blowout," where the sheer force tears the comb apart.

Always use a model with adjustable speed control, and always begin on the lowest possible setting, gradually increasing the speed only after you have confirmed the load is stable and balanced.

Your Checklist for a Damage-Free Extraction

Follow these guidelines to protect your equipment and your harvest.

- If your primary focus is a small, hobbyist harvest: Master the art of balancing frames by weight in your manual extractor, and prioritize a slow, methodical process over speed.

- If your primary focus is efficiency with a larger harvest: Invest in an electric extractor with variable speed control and ensure its capacity is appropriate for your number of hives to avoid rushing.

- If you are experiencing any violent shaking or noise: Stop immediately. The problem is almost certainly an unbalanced load, and continuing will cause damage.

A patient and methodical approach to extraction guarantees the safety of your equipment and the integrity of your hard-won honey.

Summary Table:

| Key Consideration | Why It Matters | How to Prevent Damage |

|---|---|---|

| Frame Integrity | Unsupported comb tears apart under centrifugal force. | Only use frames with wire or plastic foundation. |

| Load Balance | Unbalanced loads cause violent, damaging vibrations. | Load frames of similar weight directly opposite each other. |

| Speed Control | Starting too fast can cause a catastrophic comb blowout. | Begin on the lowest speed setting and increase gradually. |

| Stable Base | An unlevel surface amplifies vibrations, risking a tip-over. | Place the extractor on solid, level ground before starting. |

Protect your investment and maximize your honey yield with the right equipment. Whether you're a commercial apiary or a beekeeping equipment distributor, HONESTBEE supplies durable, commercial-grade honey extractors and beekeeping supplies designed for efficiency and longevity. Our wholesale-focused operations ensure you get the reliable equipment you need for a damage-free harvest season. Contact HONESTBEE today to discuss your needs and get a quote!

Visual Guide

Related Products

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What equipment is used for honey harvest? Essential Tools for Every Beekeeper

- What machines are needed in beekeeping besides basic tools? Scale Your Honey Harvest Efficiently

- What are the best storage conditions for a honey extractor? Protect Your Investment for Next Season

- How is honey extracted commercially? Maximize Your Apiary's Efficiency and Honey Yield

- What are the benefits of using a honey extractor? Maximize Harvest & Save Bee Energy