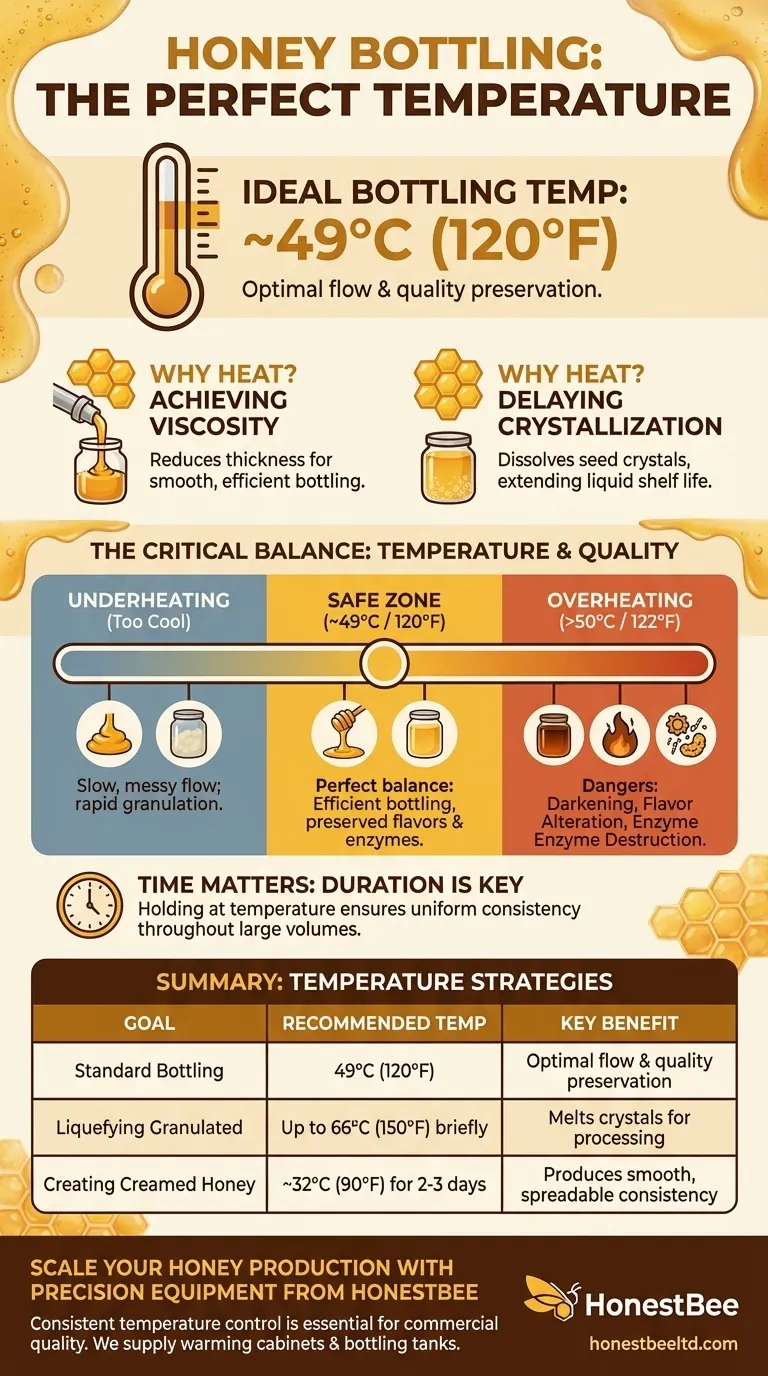

For bottling, the ideal temperature to heat your honey is approximately 49°C (120°F). This temperature strikes the perfect balance, making the honey fluid enough for a smooth and efficient bottling process while being low enough to preserve its delicate flavors, aromas, and beneficial enzymes. Holding the honey at this temperature allows it to reach a uniform consistency, ensuring a high-quality final product.

The goal of heating honey for bottling is not merely to warm it, but to achieve optimal viscosity for flow while safeguarding its natural quality. The correct temperature is the key to balancing bottling efficiency with product integrity.

Why Heating Honey is a Necessary Step

Raw honey straight from the hive is often thick and can be difficult to work with. Gently applying heat is a standard and necessary practice in honey processing for several key reasons.

Achieving the Right Viscosity

Honey's thickness, or viscosity, is its primary challenge during bottling. Warming honey significantly reduces its viscosity, allowing it to flow smoothly and quickly through pipes, filters, and bottling nozzles. This ensures an efficient process and clean, consistent fill levels in your jars.

Delaying Crystallization

All natural honey will eventually crystallize. This process is accelerated by the presence of microscopic "seed" crystals. Heating honey to the proper temperature dissolves these existing sugar crystals, which dramatically slows the rate of future crystallization and keeps the honey liquid on the shelf for much longer.

The Critical Balance: Temperature vs. Quality

While heating is necessary, it is a delicate process. The relationship between temperature, time, and honey quality is something every producer must master.

The "Safe Zone" for Bottling

The target of 49°C (120°F) is considered the industry standard "safe zone." At this temperature, honey becomes suitably fluid for bottling, and any fine crystals are dissolved. Most importantly, it is low enough to prevent significant degradation of the honey's natural enzymes and flavor compounds.

The Dangers of Overheating

Exceeding this safe zone, especially for prolonged periods, can be destructive. As temperatures rise above 50°C (122°F), you begin to risk:

- Darkening the Color: Excessive heat can caramelize the sugars, permanently darkening the honey.

- Altering the Flavor: The delicate and unique floral notes of the honey can be "cooked off," resulting in a generic, flatly sweet taste.

- Destroying Enzymes: Heat rapidly degrades beneficial enzymes like diastase and invertase, which are key markers of high-quality, raw honey.

The Problem with Underheating

Failing to heat the honey sufficiently also creates problems. If the honey is too cool and thick, bottling becomes slow, messy, and inefficient. Furthermore, if the temperature is not high enough to dissolve all sugar crystals, the honey will likely begin to granulate in the jar very quickly.

Understanding the Trade-offs

The correct temperature is only one part of the equation; the duration of heating is just as important.

Time as a Critical Factor

The reference to holding honey at bottling temperature for 24 hours is best understood as the time required for a large volume (e.g., in a bulk tank or warming cabinet) to reach a uniform temperature throughout. The principle is that a lower temperature held for a longer duration is generally safer for the honey than a high temperature applied quickly.

Adjusting for Granulated Honey

Your starting material dictates your approach. If you are starting with fully crystallized or "set" honey, a different strategy is required. Gently warming it at a much lower temperature—around 32°C (90°F) for 2-3 days—can be effective for producing a soft-set or creamed honey. For heavily granulated honey that needs to be fully liquefied for bottling, a brief period at a higher temperature (up to 66°C / 150°F) may be necessary only to melt the crystals, after which it should be cooled back down to the 49°C (120°F) bottling temperature.

Making the Right Choice for Your Goal

Your specific goal will determine your exact heating strategy.

- If your primary focus is preserving raw honey characteristics: Use the absolute minimum heat required to make the honey workable, and consider bottling in a very warm room to aid flow, accepting that crystallization may occur sooner.

- If your primary focus is commercial shelf stability and clarity: Adhere strictly to the 49°C (120°F) guideline to ensure all crystals are dissolved before bottling for a long-lasting liquid product.

- If you are dealing with heavily granulated honey: Use a two-step process by first liquefying the honey completely, then allowing it to cool to the ideal 49°C (120°F) before you begin bottling.

Mastering temperature control is the key to bottling honey that is both beautiful in the jar and true to its natural quality.

Summary Table:

| Goal | Recommended Temperature | Key Benefit |

|---|---|---|

| Standard Bottling | 49°C (120°F) | Optimal flow & quality preservation |

| Liquefying Granulated Honey | Up to 66°C (150°F) briefly | Melts crystals for processing |

| Creating Creamed Honey | ~32°C (90°F) for 2-3 days | Produces a smooth, spreadable consistency |

Scale Your Honey Production with Precision Equipment from HONESTBEE

Consistent temperature control is essential for commercial honey quality and efficiency. HONESTBEE supplies durable, high-performance honey warming cabinets, bottling tanks, and other essential beekeeping supplies to commercial apiaries and beekeeping equipment distributors.

We help you protect your product's integrity while streamlining your bottling line. Contact our wholesale experts today to discuss equipment solutions for your operation.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- How do automated filling and sealing machines contribute to the stability of bee pollen? Protect Potency and Shelf Life

- What is the use of a juice filling machine? Boost Your Production Speed & Consistency

- How do industrial automatic honey-filling machines contribute to product quality? Ensure Precision and Purity

- How do high-precision honey filling machines contribute to the competitiveness of honey production? Maximize Your ROI

- How does the implementation of planting enrichment plans impact honey processing and filling machinery requirements?

- How do automatic honey filling machines ensure product quality? 6 Ways to Achieve Consistency and Purity

- What are the technical considerations for the multi-point sampling design of industrial filling tanks? Ensure Precision

- What are the applications and benefits of an automatic filling and packaging line in large-scale honey processing?