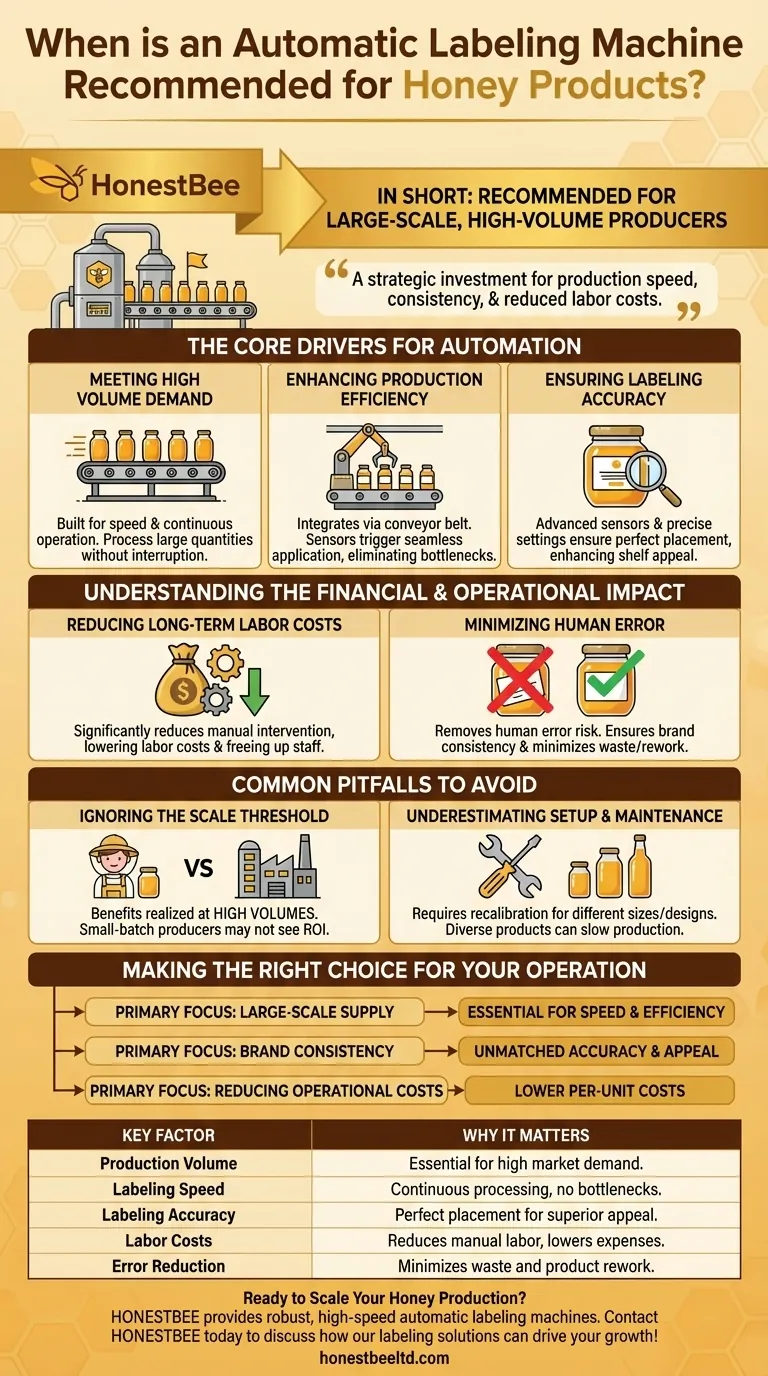

In short, an automatic labeling machine is recommended for honey producers who operate at a large scale. When your production volume is high, such as in a large processing plant, these machines are essential for applying labels quickly and efficiently enough to meet significant market demand.

The decision to invest in an automatic honey labeler is a strategic one. It becomes necessary when the need for production speed, labeling consistency, and reduced labor costs outweighs the capabilities of manual or semi-automatic methods.

The Core Drivers for Automation

Choosing to automate your labeling process is driven by specific operational pressures and goals. For high-volume honey producers, the benefits directly address the primary challenges of scaling up.

Meeting High Volume Demand

An automatic labeling machine is built for speed and continuous operation. Unlike manual labeling, which is limited by human pace, an automated system can process a large quantity of honey packages without interruption.

This capability is critical for large honey processing plants that need to fulfill substantial orders consistently and on tight deadlines.

Enhancing Production Efficiency

The machine integrates directly into a production line via a conveyor belt. As bottles or jars move into the labeling area, sensors detect their arrival and trigger the application process.

This seamless, automatic workflow eliminates bottlenecks, significantly reducing the time it takes to get products ready for shipment and increasing overall production efficiency.

Ensuring Labeling Accuracy

Manual labeling can lead to crooked labels, wrinkles, or inconsistent placement. Automatic machines use advanced sensors and precise mechanical settings to control label placement perfectly every time.

This high degree of accuracy ensures a tight, clean fit, which enhances the product's aesthetic appeal and marketability on competitive store shelves.

Understanding the Financial and Operational Impact

Beyond speed, automation introduces fundamental changes to your financial and operational models. The investment creates value by optimizing resources and improving quality control.

Reducing Long-Term Labor Costs

While there is an upfront investment, an automatic machine significantly reduces the need for manual intervention. This lowers ongoing labor costs and frees up your staff to focus on more complex tasks that require human oversight.

Minimizing Human Error

An automated system removes the risk of human error from the labeling process. It applies each label to the preset position without variation, which minimizes wasted labels, reduces product rework, and ensures brand consistency across your entire product run.

Common Pitfalls to Avoid

While powerful, an automatic labeling machine is not a universal solution. Understanding its limitations is key to making an informed decision.

Ignoring the Scale Threshold

The primary benefit of these machines is realized at high volumes. For small-batch, artisan, or hobbyist honey producers, the significant capital investment is unlikely to provide a positive return. Manual or semi-automatic solutions are often more appropriate at this scale.

Underestimating Setup and Maintenance

Switching between different bottle sizes or label designs requires recalibration and setup time. Operations with a highly diverse and frequently changing range of products may find this changeover process introduces complexity that can slow down production if not managed well.

Making the Right Choice for Your Operation

Ultimately, the right choice depends on your specific business goals and production scale.

- If your primary focus is large-scale market supply: An automatic labeling machine is an essential investment to achieve the necessary speed and efficiency.

- If your primary focus is improving brand consistency and shelf appeal: Automation provides unmatched accuracy, ensuring every product looks professional and uniform.

- If your primary focus is reducing long-term operational costs: The machine's ability to minimize labor needs and reduce error-related waste offers a clear path to lower per-unit costs.

Investing in automation is a decisive step toward scaling your honey operation for consistent growth and quality.

Summary Table:

| Key Factor | Why It Matters for Automation |

|---|---|

| Production Volume | Essential for large-scale operations to meet high market demand. |

| Labeling Speed | Processes bottles/jars continuously via conveyor belt, eliminating bottlenecks. |

| Labeling Accuracy | Advanced sensors ensure perfect placement every time for superior shelf appeal. |

| Labor Costs | Reduces long-term manual labor needs, lowering operational expenses. |

| Error Reduction | Minimizes human error, wasted labels, and product rework. |

Ready to Scale Your Honey Production with Precision Labeling?

As a trusted supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the robust, high-speed automatic labeling machines you need to meet large-scale demand. Our wholesale-focused operations ensure you get reliable equipment that enhances your production line's efficiency and guarantees a professional, consistent look for your brand.

Contact HONESTBEE today to discuss how our labeling solutions can drive your growth!

Visual Guide

Related Products

- Automatic In-Line Flat Surface Labeling Machine

- Semi Automatic Round Bottle Labeling Machine

- Automatic Dual Sided In Line Labeling Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

People Also Ask

- What factors should be considered when designing the size and shape of a honey label? Optimize Your Packaging Design

- What are the advantages of using automated labeling and sealing equipment for honey export? Boost Quality & Compliance

- What types of content are typically included on a honey label? Essential Branding and Compliance Guide

- How do high-precision labeling and coding machines influence honey consumer trust? Build Brand Integrity and Value

- How does a honey bottle labeling machine improve work efficiency? Boost Speed, Accuracy & Profits

- How does container shape influence the efficiency of the honey labeling process? Choose the Best Jar for Automation

- What are the characteristics and benefits of using an automatic labeling machine for honey products? Boost Your Brand

- What is the role of labeling machines in the packaging process? Boost Precision, Efficiency, and Brand Compliance