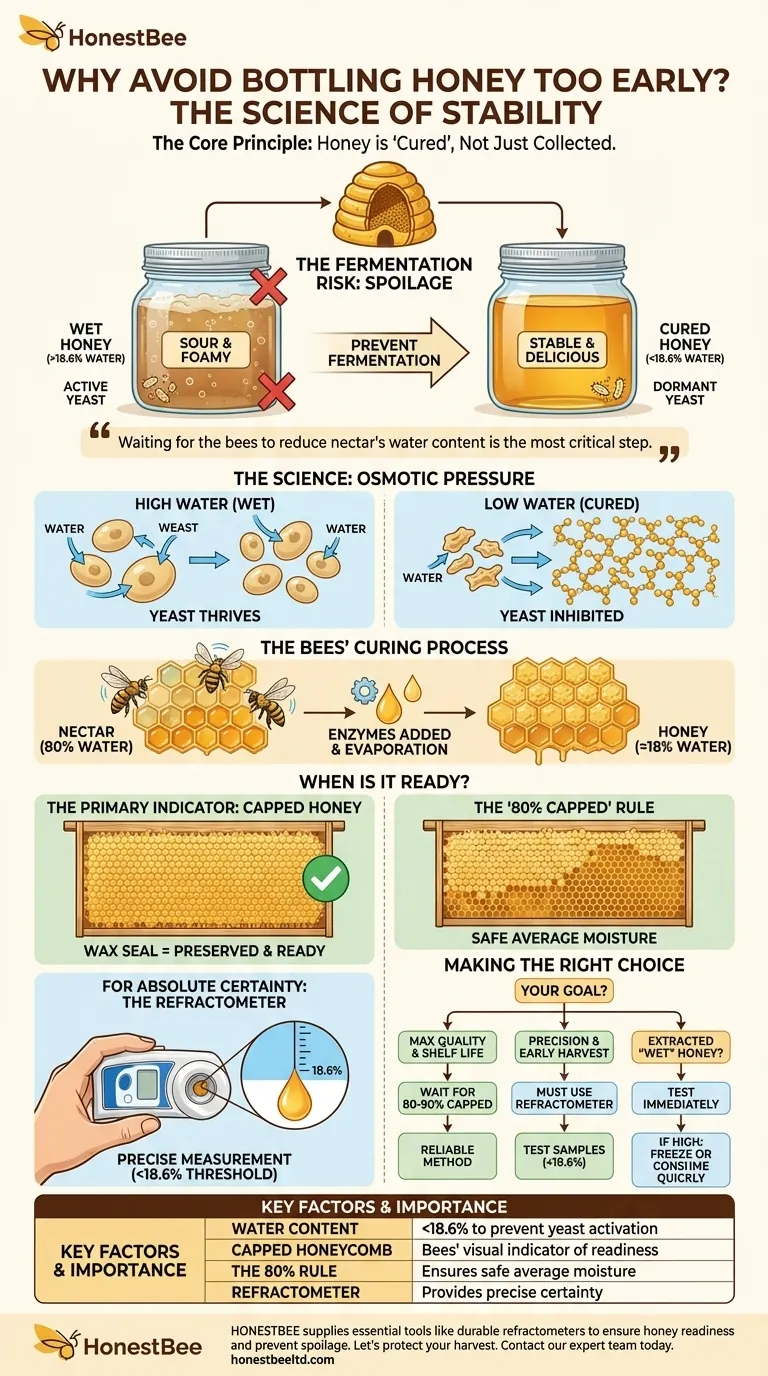

The primary reason to avoid bottling honey too early is to prevent fermentation. Honey with high water content—typically above 18.6%—creates an environment where naturally present yeasts can thrive, consuming the sugars and spoiling the product. This process ruins the honey's flavor, texture, and shelf life, turning your harvest into a sour, fizzy liquid.

The core principle is that honey is not simply collected; it is "cured." Waiting for the bees to complete this curing process by reducing the nectar's water content is the single most critical step to ensure your honey is stable, delicious, and will last indefinitely.

The Science of Honey Stability

Honey's incredible shelf life is not an accident; it's a result of its unique chemical properties, primarily its low water content and high sugar concentration.

What Makes Honey Spoil?

All honey contains dormant wild yeasts. When the water content is sufficiently low (under 18.6%), the high sugar concentration creates immense osmotic pressure, drawing water out of any yeast cells and preventing them from activating.

If honey is harvested "wet," or uncured, these yeasts have enough water to metabolize the sugars. They produce carbon dioxide and alcohol, which can then turn into acetic acid, giving the honey a sour, fermented taste and a foamy appearance.

The Bees' Curing Process

Nectar collected from flowers can have a water content as high as 80%. Bees transform this into honey through two key actions.

First, they add enzymes that begin breaking down complex sugars. Second, and most critically, they actively dehydrate the nectar by fanning their wings over the honeycomb, creating airflow that evaporates excess water until the concentration reaches that stable threshold of around 18%.

How to Know When Honey Is Ready

The bees themselves provide the clearest signal that the honey is cured and ready for long-term storage.

The Primary Indicator: Capped Honey

Once the bees have reduced the moisture to the correct level, they seal the honeycomb cell with a fresh layer of beeswax. This is known as capping.

A frame of honey that is fully or mostly capped is the beekeeper's green light for harvesting. This wax seal is the bees' way of certifying that the honey underneath is preserved and ready.

The "80% Capped" Rule of Thumb

In practice, you rarely find a frame that is 100% capped. A widely accepted guideline is to harvest frames that are at least 80% capped.

The small amount of uncapped honey on such a frame will typically have its moisture content averaged out by the much larger volume of cured, capped honey, usually resulting in a safe final mixture.

For Absolute Certainty: The Refractometer

The most precise way to ensure your honey is safe to bottle is to use a honey refractometer. This simple tool measures the water content of a liquid by measuring how it bends light.

A single drop of honey is all that's needed. For beekeepers who want to eliminate all guesswork, a refractometer provides a definitive reading, ensuring every batch is below the 18.6% fermentation threshold.

Understanding the Trade-offs

Harvesting honey is a balance of patience and practicality. Pushing the process can lead to significant problems.

The Risk of Harvesting Uncapped Frames

Extracting a frame with large, uncapped sections is a major gamble. This "wet" honey will raise the overall moisture level of your entire batch, potentially causing all of it to ferment.

While you might gain a little more honey in the short term, you risk losing the whole harvest to spoilage. The time and effort saved by not waiting are insignificant compared to the potential for total loss.

Can "Wet" Honey Be Saved?

If you mistakenly extract honey with high moisture content, it is not always a total loss, but the solutions are difficult.

Some commercial operations use expensive dehydrators to lower the water content after extraction. For a hobbyist, a simpler option is to freeze the wet honey for immediate use, as freezing will prevent fermentation. However, it will not make the honey shelf-stable.

Making the Right Choice for Your Harvest

Your approach to harvesting should be guided by your goal for the final product.

- If your primary focus is maximum quality and indefinite shelf life: Wait until your frames are at least 80-90% capped. This is the most reliable, time-tested method for ensuring a stable product.

- If your primary focus is precision and you must harvest earlier: You must use a honey refractometer. Test samples from the uncapped areas to ensure the water content is safely below 18.6% before you extract.

- If you have already extracted potentially "wet" honey: Test it with a refractometer immediately. If it's too high, either freeze it for personal use or consume it quickly, as it will likely begin to ferment at room temperature.

Ultimately, patience is your greatest tool in producing high-quality honey.

Summary Table:

| Key Factor | Why It Matters |

|---|---|

| Water Content | Must be below 18.6% to prevent yeast activation and fermentation. |

| Capped Honeycomb | Bees cap cells with wax when honey is cured; the primary visual indicator of readiness. |

| The 80% Rule | Harvest when frames are at least 80% capped to ensure a safe average moisture level. |

| Refractometer | Provides a precise measurement of water content for absolute certainty. |

Produce stable, high-quality honey with confidence.

As a commercial beekeeper or distributor, your reputation depends on the quality and shelf life of your product. HONESTBEE supplies the essential tools—including durable refractometers and extraction equipment—to help you accurately gauge honey readiness and prevent costly spoilage.

Let's protect your harvest. Contact our expert team today to discuss the right supplies for your apiary's scale and needs.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- Digital Honey Refractometer for Precision Measurement of Optimal Honey Quality

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

People Also Ask

- How is a manual refractometer used to determine honey quality? Essential Moisture Control for Commercial Beekeeping

- What should be considered regarding the measurement range of a honey refractometer? Ensure Peak Honey Quality

- What is the primary function of a desktop refractometer? Ensure Honey Quality and Prevent Fermentation

- Why is a refractometer necessary for determining the moisture content and quality grade of honey? Ensure Market Success

- Why is a high-precision refractometer considered essential for honey quality? Master Moisture Control for Stability