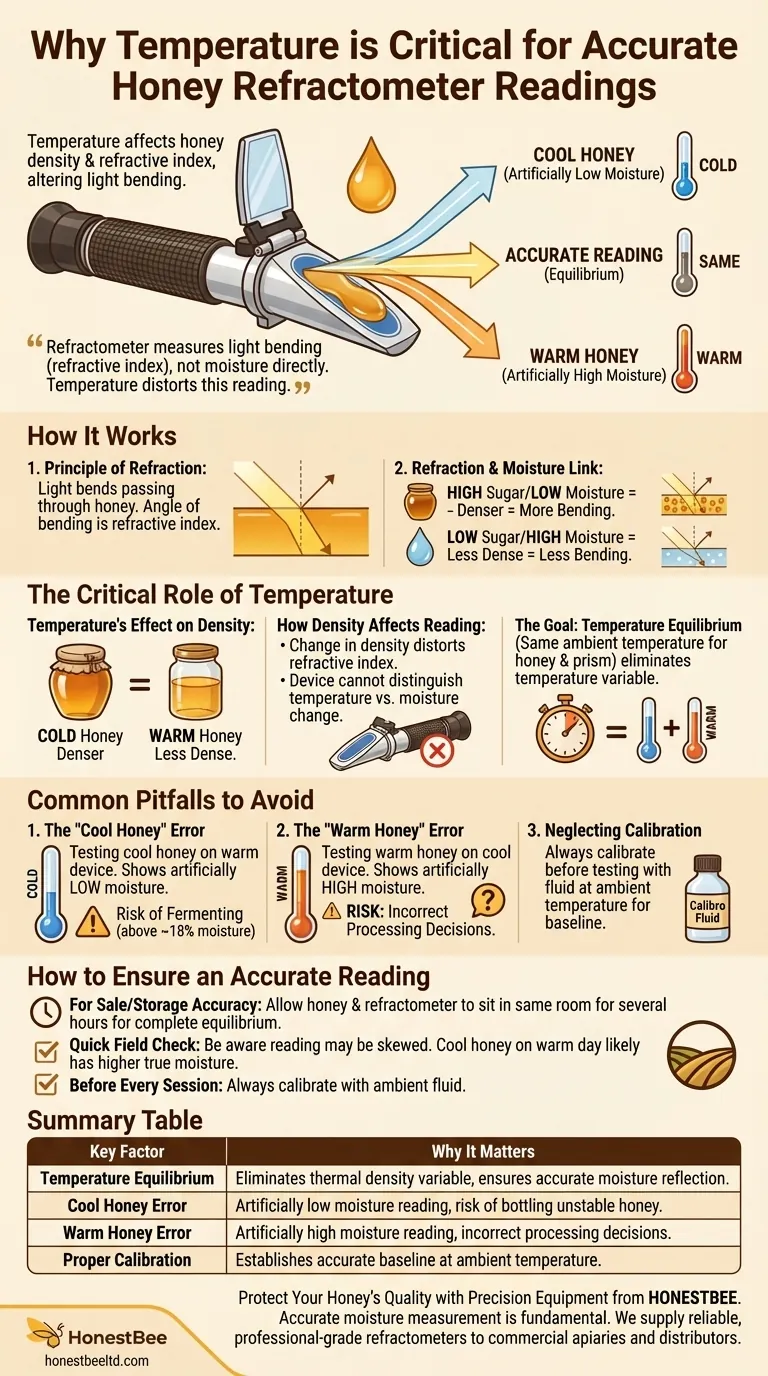

Temperature is critical for an accurate honey refractometer reading because it directly affects the density and refractive index of the honey. If the honey and the refractometer are at different temperatures, the measurement of light bending through the sample will be distorted, leading to a false reading of the honey's true moisture content.

A refractometer does not directly measure moisture; it measures how light bends (refractive index). Since temperature alters this property, achieving temperature equilibrium between your honey and the device is the only way to ensure the reading reflects the actual water content, not just thermal effects.

How a Refractometer Measures Honey Moisture

The Principle of Refraction

A refractometer works by passing light through a thin layer of honey. It measures the angle at which the light bends, a property known as the refractive index.

The Link Between Refraction and Moisture

This angle of bending is directly correlated to the concentration of dissolved solids—primarily sugars—in the honey.

Honey with a high sugar concentration (low moisture) is denser, causing light to bend more. Honey with a lower sugar concentration (high moisture) is less dense, causing light to bend less. The device's scale is calibrated to translate this angle into a moisture percentage.

The Critical Role of Temperature

Temperature's Effect on Density

The physical properties of any liquid, including honey, change with temperature. When honey is cold, it becomes thicker and denser. When it is warm, it becomes thinner and less dense.

How Density Affects the Reading

This change in density directly alters the refractive index. A refractometer cannot distinguish between a change in density caused by moisture content and one caused by temperature.

If you place cold, dense honey on a room-temperature refractometer, the light will bend more than it should. The device will interpret this as a higher sugar concentration, giving you an artificially low moisture reading.

The Goal: Temperature Equilibrium

To get a true reading, you must eliminate temperature as a variable. By ensuring the honey and the refractometer prism are at the same ambient temperature, you guarantee that the only significant factor influencing the refractive index is the honey's moisture content.

Common Pitfalls to Avoid

The "Cool Honey" Error

Testing honey that is cooler than the refractometer is the most dangerous mistake. It will show a lower moisture percentage than is actually present, potentially leading you to bottle honey that is at risk of fermenting (above ~18% moisture).

The "Warm Honey" Error

Conversely, testing honey that is warmer than the device will produce an artificially high moisture reading. While less risky than the "cool honey" error, it is still inaccurate and can lead to incorrect processing decisions.

Neglecting Calibration

Always calibrate your refractometer before a testing session. Use the supplied calibration fluid and ensure both the fluid and the device have been sitting at the same room temperature to establish a correct baseline.

How to Ensure an Accurate Reading

Follow these guidelines to ensure your measurements are reliable and your honey quality is protected.

- If your primary focus is accuracy for sale or storage: Allow your honey sample and your refractometer to sit in the same room for several hours to reach complete temperature equilibrium before testing.

- If you are performing a quick field check: Be aware that the reading may be skewed. If you test cool honey on a warm day, know that the true moisture content is likely higher than what the reading shows.

- Before every testing session: Always calibrate the refractometer with its fluid at ambient temperature to ensure your starting point is accurate.

Mastering this process transforms the refractometer from a simple gadget into a precise scientific instrument for safeguarding your honey.

Summary Table:

| Key Factor | Why It Matters |

|---|---|

| Temperature Equilibrium | Eliminates variable of thermal density change, ensuring refractive index reflects only moisture content. |

| Cool Honey Error | Causes artificially low moisture reading, risking fermentation by bottling unstable honey. |

| Warm Honey Error | Causes artificially high moisture reading, leading to incorrect processing decisions. |

| Proper Calibration | Establishes an accurate baseline for measurements when done at ambient temperature. |

Protect Your Honey's Quality with Precision Equipment from HONESTBEE

Accurate moisture measurement is fundamental to producing stable, high-quality honey. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with reliable, professional-grade refractometers and other essential beekeeping supplies through our wholesale-focused operations.

Ensure every batch meets quality standards. Contact our experts today to find the right equipment for your operation's scale and needs.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- Digital Honey Refractometer for Precision Measurement of Optimal Honey Quality

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- Why is a refractometer necessary for determining the moisture content and quality grade of honey? Ensure Market Success

- What role does a high-precision refractometer play in honey moisture analysis? Ensure Honey Quality & Stability

- How is a manual refractometer used to determine honey quality? Essential Moisture Control for Commercial Beekeeping

- Why is an industrial-grade refractometer used to measure honey moisture? Ensure Stability and Prevent Fermentation

- Why is a high-precision refractometer considered essential for honey quality? Master Moisture Control for Stability