For commercial beekeepers and distributors, honey filtration isn’t just a processing step—it’s a critical safeguard for product integrity, regulatory compliance, and consumer trust. This guide breaks down the science, standards, and optimization strategies behind effective honey filtration, equipping industry professionals with actionable insights to elevate their product quality.

The Science of Honey Filtration

What Impurities Are Removed and Why It Matters

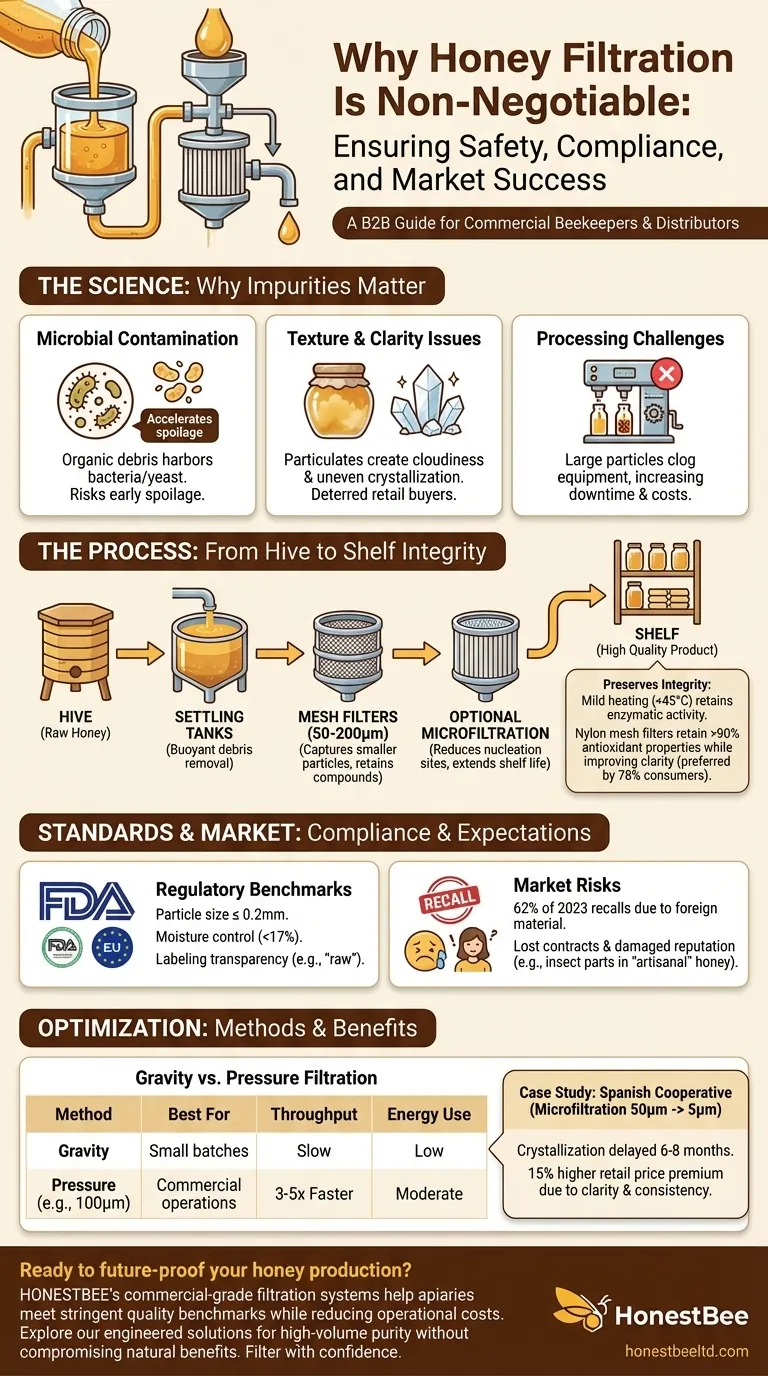

Raw honey straight from the hive contains wax fragments, pollen grains, bee parts, and environmental debris like dust or plant matter. While some consumers value "unfiltered" honey for its perceived naturalness, these impurities pose tangible risks:

- Microbial contamination: Organic debris can harbor bacteria or yeast, accelerating spoilage.

- Texture and clarity issues: Particulates create cloudiness and uneven crystallization, deterring retail buyers.

- Processing challenges: Large particles clog bottling equipment, increasing downtime.

Research shows that even mild heating (below 45°C) during filtration preserves enzymatic activity while improving flow efficiency—striking a balance between purity and nutritional retention.

From Hive to Shelf: How Filtration Preserves Integrity

Modern filtration systems use a staged approach:

- Settling tanks: Allow buoyant wax and debris to rise for easy removal.

- Mesh filters (50–200 microns): Capture smaller particles without stripping beneficial compounds.

- Optional microfiltration: Reduces crystallization rates by removing nucleation sites (e.g., pollen), extending shelf life by months.

A study cited by industry experts found that honey filtered through nylon meshes retained over 90% of its antioxidant properties while achieving visual clarity preferred by 78% of consumers in blind tests.

Industry Standards and Consumer Expectations

Meeting Regulatory Benchmarks for Honey Purity

Global food safety agencies, including the FDA and EU Commission, mandate that commercial honey must be "free from foreign matter" and "processed to prevent fermentation." Key compliance checkpoints:

- Particle size limits: Most jurisdictions require particles ≤ 0.2mm.

- Moisture content: Filtration aids in controlling water activity (

- Labeling transparency: Terms like "raw" or "unfiltered" trigger specific testing protocols.

How Unfiltered Honey Risks Brand Reputation

A 2023 market analysis revealed that 62% of honey recalls stemmed from contamination by foreign materials—a preventable issue with proper filtration. Case in point: A Midwest apiary lost a major grocery contract after consumers reported finding insect parts in jars, despite the honey’s artisanal appeal.

Optimizing the Filtration Process

Comparing Methods: Gravity vs. Pressure Filtration

| Method | Best For | Throughput | Energy Use |

|---|---|---|---|

| Gravity | Small batches ( | Slow | Low |

| Pressure | Commercial operations | 3–5x faster | Moderate |

Pressure systems with stainless steel filters (e.g., 100-micron screens) are gaining traction for their hygienic design and scalability. One distributor using this method reduced filtration time by 40% while cutting post-process crystallization complaints by half.

Case Study: Increased Shelf Life Post-Microfiltration

A Spanish cooperative implemented a two-stage microfiltration system (50μm → 5μm) and observed:

- Crystallization delayed by 6–8 months (vs. unfiltered batches) due to removed nucleation sites.

- Higher retail pricing power: Clarity and consistency justified a 15% price premium.

Ready to future-proof your honey production? HONESTBEE’s commercial-grade filtration systems help apiaries and distributors meet stringent quality benchmarks while reducing operational costs. Explore our Product Name—engineered for high-volume purity without compromising honey’s natural benefits.

For beekeeping professionals, every drop counts. Filter with confidence.

Visual Guide

Related Products

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Professional Thermostatic Conical Honey Melter

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

Related Articles

- How to Choose Between Semi-Automatic and Fully Automatic Honey Filling Machines

- The Unseen Battle in Every Honey Bucket: Heat, Time, and Quality

- Centrifugal Extractors vs. Honey Presses: Choosing the Right Tool for Your Beekeeping Goals

- The Unseen Cost of Manual Honey Filling: A Case for Automation

- How Honey Processing Affects Nutrition: Science-Backed Insights for Healthier Choices