At their core, filling machines work by dispensing a precise, predetermined amount of product into a container. This process is the backbone of modern packaging, designed to ensure accuracy, consistency, and speed, whether handling liquids, powders, or granulated goods. The specific mechanism used is chosen to perfectly match the properties of the product being filled.

The central challenge in filling is control. How a machine achieves this control depends entirely on the product's physical properties, especially its viscosity. The choice between the primary mechanisms—piston, gravity, or pump—is the most critical decision in designing an effective filling line.

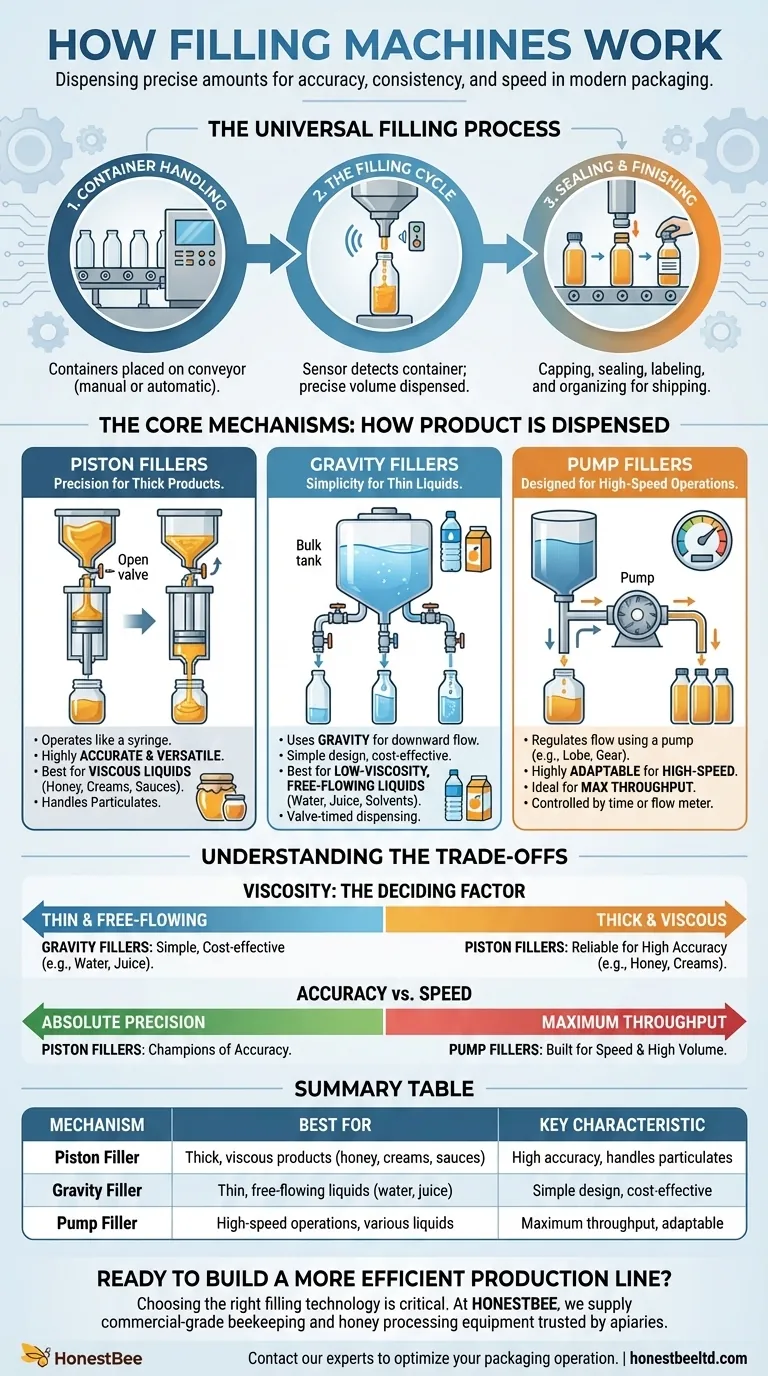

The Universal Filling Process

While the dispensing technology varies, most automated filling operations follow a similar sequence of events. This workflow is designed to move containers through the system efficiently and without human error.

Step 1: Container Handling

The process begins with empty containers being placed onto a conveyor system. This can be done manually by an operator or automatically by auxiliary equipment for higher-speed operations.

Step 2: The Filling Cycle

The containers are then transported to the filling station. A sensor detects the container's presence and positions it directly under a filling nozzle. The machine dispenses the exact volume of product required.

Step 3: Sealing and Finishing

Once filled, the container moves along the conveyor to subsequent stations. Here, it is typically capped, sealed, and often labeled before being organized for final packaging and shipping.

The Core Mechanisms: How Product is Dispensed

The "magic" of a filling machine happens at the nozzle. The technology used to move the product from a bulk source (like a hopper) into the container is what truly defines the machine.

Piston Fillers: Precision for Thick Products

A piston filler operates much like a large syringe. A valve opens, allowing product to flow from a hopper into a precisely machined cylinder as the piston retracts.

Once the cylinder is full, the valve switches, and the piston pushes forward, forcing the exact volume of product out through the nozzle and into the container. This mechanism is highly accurate and versatile, making it the standard for viscous liquids like honey, creams, and sauces, as well as products containing particulates.

Gravity Fillers: Simplicity for Thin Liquids

A gravity filler is the simplest design. It uses a bulk tank or hopper positioned above the filling nozzles. As the name implies, gravity is the force that causes the product to flow downward.

Valves at the nozzles open for a set amount of time to allow the product to flow into the containers. This method is straightforward and effective for low-viscosity, free-flowing liquids like water, juice, or solvents.

Pump Fillers: Designed for High-Speed Operations

Pump-based systems regulate product flow using a pump (such as a lobe, gear, or peristaltic pump) connected to the filling nozzles. The amount of product dispensed is controlled by precisely managing the pump's operation time or by using a flow meter.

This method is highly adaptable and is often chosen for high-speed production lines where throughput is the primary concern.

Understanding the Trade-offs

Choosing a filling mechanism is not about finding the "best" one, but the right one for your specific product and operational goals. Each technology comes with distinct advantages and limitations.

Viscosity: The Deciding Factor

This is the most critical variable. Trying to use a gravity filler for a thick paste will result in extremely slow and inconsistent fills. Conversely, using a complex piston filler for a water-thin liquid may be unnecessarily expensive.

- Thick & Viscous: Piston fillers provide the force needed to move the product accurately.

- Thin & Free-Flowing: Gravity fillers are a simple, cost-effective solution.

Accuracy vs. Speed

There is often a trade-off between absolute precision and maximum throughput.

Piston fillers are champions of accuracy, volumetrically dispensing the same amount every single time. Pump fillers are often built for speed, making them ideal for high-volume manufacturing where minor variations are acceptable.

Auxiliary Features

For some products, additional features are necessary. For example, when filling honey, a machine may incorporate a gentle heating system within the hopper. This reduces the honey's viscosity, allowing it to flow more smoothly and preventing air bubbles from forming during the fill.

Making the Right Choice for Your Product

To select the correct technology, you must start with a clear understanding of your product's properties and your production goals.

- If your product is thick, viscous, or contains particles (e.g., honey, creams, salsa): A piston filler is the most reliable choice for achieving high accuracy and consistency.

- If your product is a thin, free-flowing liquid (e.g., water, juice, alcohol): A gravity filler provides a simple, dependable, and cost-effective solution.

- If your primary focus is maximizing production speed for a range of liquid types: A pump-based filling system offers the high throughput and flexibility needed for large-scale operations.

Ultimately, selecting the correct filling technology is the foundation of an efficient, consistent, and profitable production line.

Summary Table:

| Mechanism | Best For | Key Characteristic |

|---|---|---|

| Piston Filler | Thick, viscous products (honey, creams, sauces) | High accuracy, handles particulates |

| Gravity Filler | Thin, free-flowing liquids (water, juice) | Simple design, cost-effective |

| Pump Filler | High-speed operations, various liquids | Maximum throughput, adaptable |

Ready to Build a More Efficient Production Line?

Choosing the right filling technology is critical for accuracy, speed, and profitability. At HONESTBEE, we supply the commercial-grade beekeeping and honey processing equipment that apiaries and distributors trust.

We can help you select the perfect piston, gravity, or pump-based filling system to handle your specific products—from raw honey to creamed honey and beyond.

Contact our experts today to discuss your production needs and discover how our wholesale-focused solutions can optimize your packaging operation.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

People Also Ask

- How does high-efficiency honey filling machinery contribute to commercialization? Scaling Your Honey Brand Effectively

- What are the technical advantages of using industrial-grade honey filling machines compared to manual filling processes?

- What are the benefits of using proper honey bottling equipment? Elevate Your Product Quality and Profitability

- How do honey filling machines and specialized packaging impact production? Boost Efficiency & Market Value

- What is the industrial value of professional honey filling and processing machinery? Maximize Your Market Value

- What are pump liquid fillers and in what scenarios are they used for honey packaging? Optimize Large-Scale Production

- What is the purpose of a Weighing Filling Machine? Ensure Precision and Profitability

- Why are automated honey filling machines critical for the commercialization of honey? Build a Consistent, Scalable Brand